Coupling system of membrane aerated biofilm and bioelectrochemistry and its application

A membrane aeration biofilm and bioelectrochemical technology, which is applied in the field of membrane aeration biofilm and bioelectrochemical coupling systems, can solve the problems of large energy consumption, weakened fixation force, and low oxygen utilization rate, and achieve low energy consumption. , no foam formation, good power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

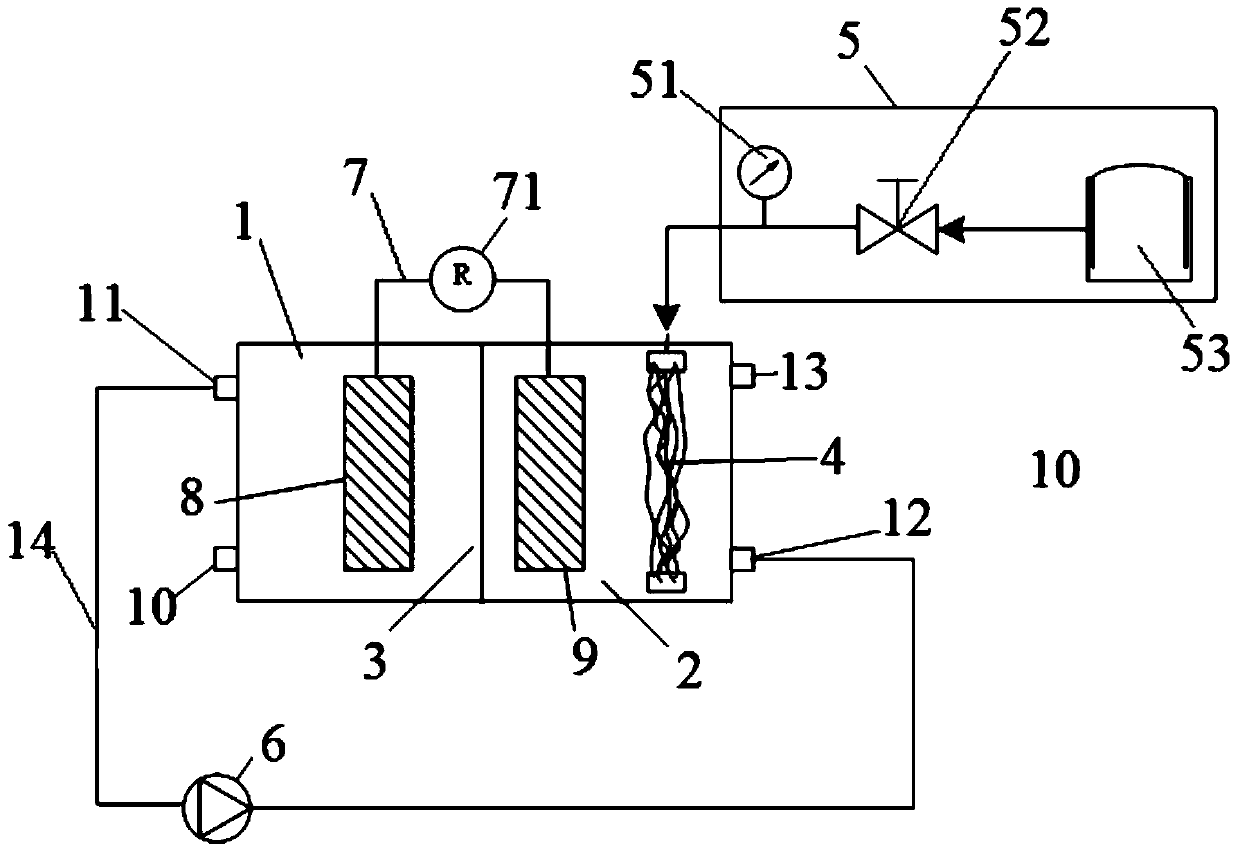

[0045] Such as figure 1 As shown, the membrane aerated biofilm and bioelectrochemical coupling system includes an anode chamber, a cathode chamber and a separation membrane 3 arranged between the anode chamber and the cathode chamber, and also includes a membrane aerated biofilm arranged in the cathode chamber 4. The external oxygen supply unit 5 connected to the membrane aeration biofilm 4 and the external pipeline 14 connecting the anode chamber and the cathode chamber, the anode chamber and the cathode chamber are respectively provided with a bioanode electrode 8 and a biocathode electrode 9, And the bioanode electrode 8 is electrically connected with the biocathode electrode 9 through the external circuit 7 . The external oxygen supply unit 5 includes a pressure gauge 51 , an airflow regulating valve 52 and an air compressor 53 sequentially connected to the membrane aerated biofilm 4 .

[0046] Wherein, the anode chamber includes an anode reaction chamber 1 and a bioanode...

Embodiment 2

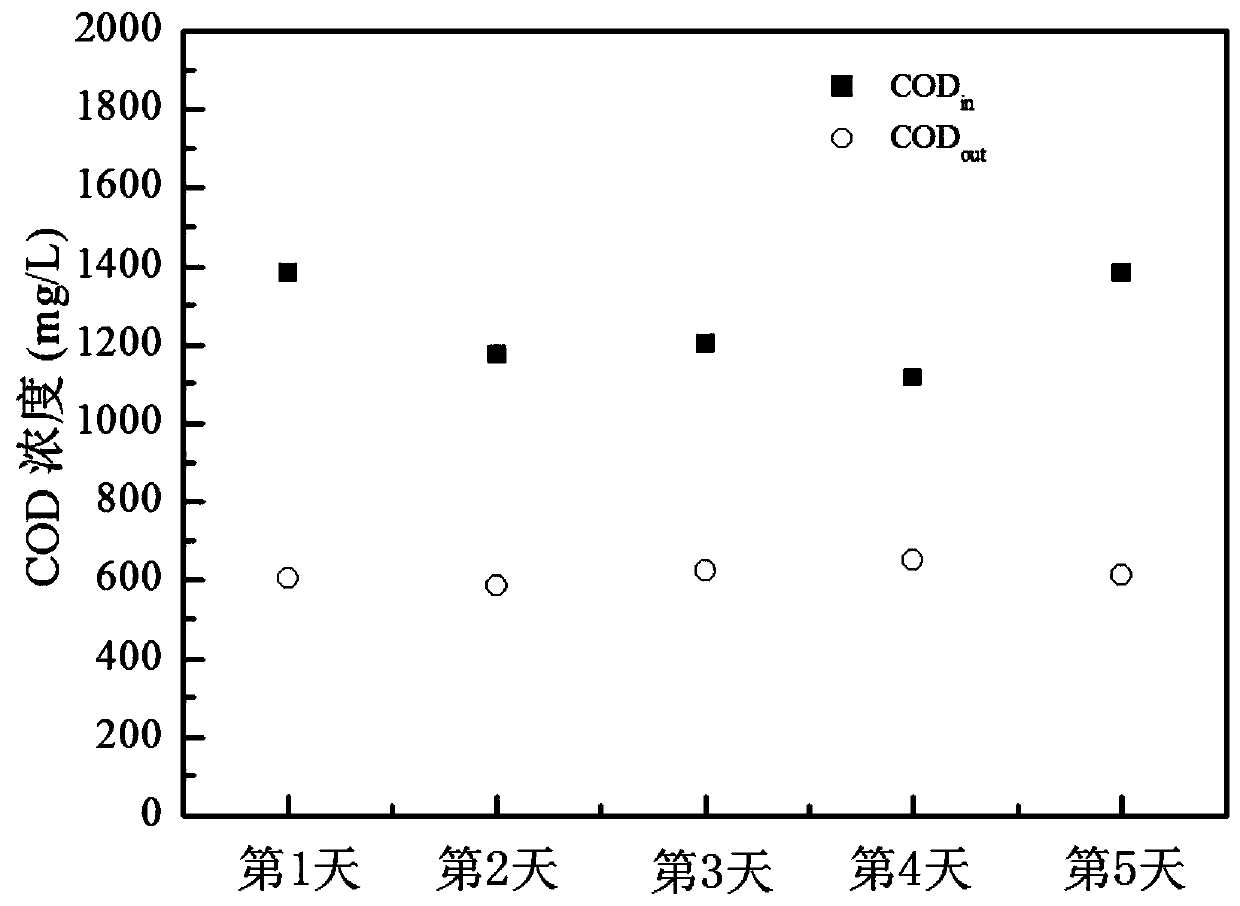

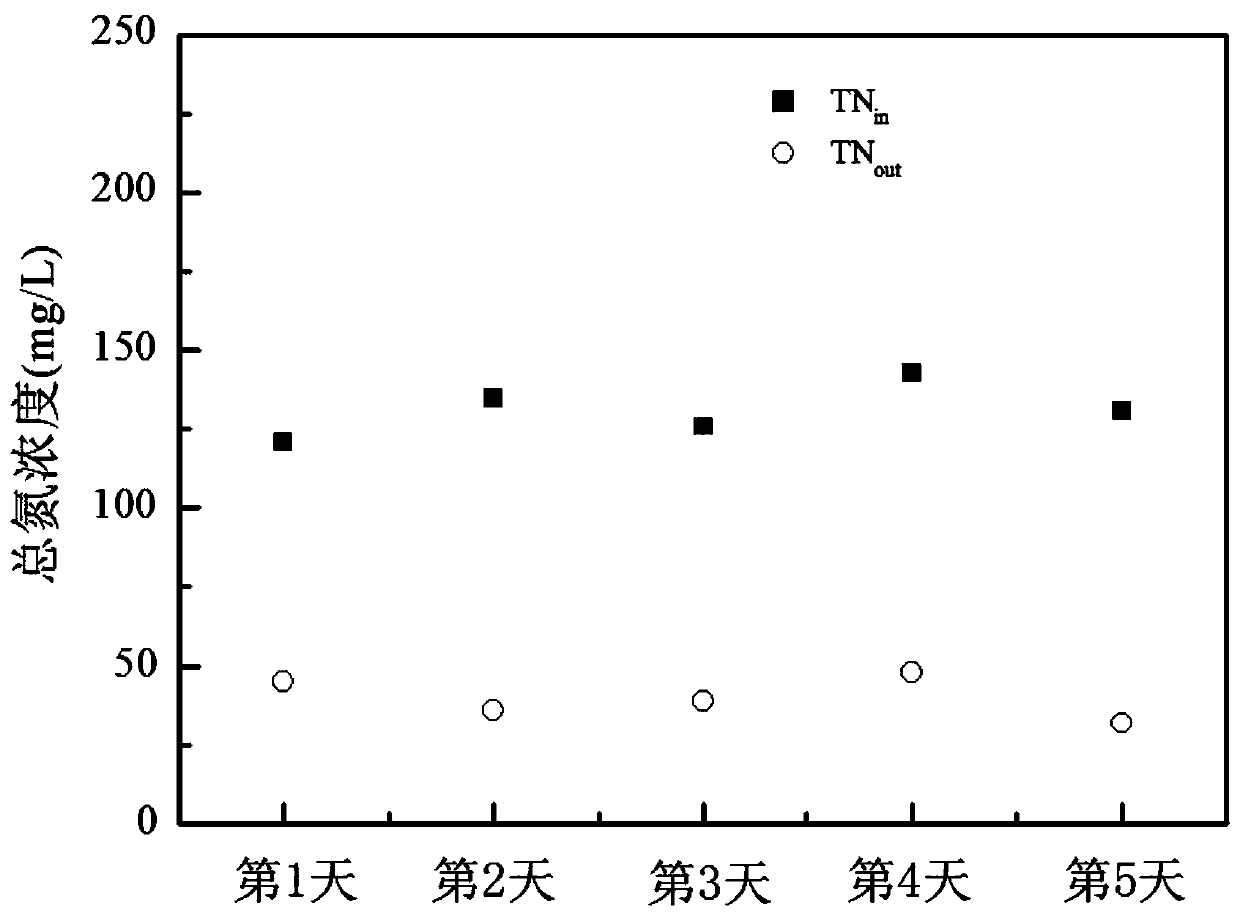

[0055] In this embodiment, the anaerobic microorganism adopts Shewanella, the anoxic microorganism adopts Steinbacillus, the separation membrane 3 is a cation exchange membrane, the electrode material of the anode electrode and the cathode electrode is carbon cloth, and the membrane aeration biofilm 4 is hydrophobic microporous membrane. The COD of the waste water is about 1000 mg / L, the total nitrogen concentration is about 100 mg / L, the oxygen supply pressure is 0.1 MPa, and the rest are the same as in Example 1.

Embodiment 3

[0057] In this embodiment, Rhodospirillum is used for anaerobic microorganisms, Trichobacterium fluorescens is used for anoxic microorganisms, the separation membrane 3 is an anion exchange membrane, the electrode material of the anode electrode and the cathode electrode is carbon felt, and the membrane aeration biofilm 4 is surface modification film. The COD of wastewater is about 1000mg / L, the total nitrogen concentration is about 500mg / L, and the oxygen supply pressure is 0.1MPa. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com