Production method of bioorganic fertilizer capable of improving soil environment

A bio-organic fertilizer and soil-improving technology, applied in the field of bio-organic fertilizer production with the effect of improving the soil environment, can solve the problems of single function, unable to solve other problems of soil, single function of soil conditioner, etc., to reduce labor and prevent Effects of soil acidification and salinization, and fertilizer conservation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

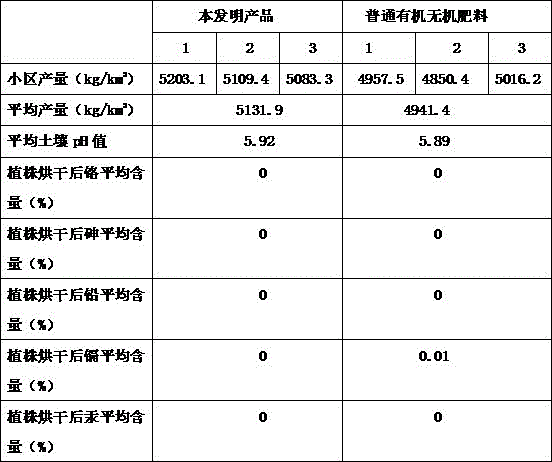

Examples

Embodiment 1

[0016] Soybean meal, potassium fulvic acid, Bacillus jellybacillus, Bacillus megaterium, soluble starch, sodium alginate, potassium polyglutamate and hydroxyethyl ethylenediamine triacetic acid in a mass ratio of 40:50:2:1:2 :1:2:2, transported to the silo by belt metering for extrusion granulation, after granulation, the product is screened to obtain the product of the present invention.

Embodiment 2

[0018] The decomposed animal manure, humic acid, molasses fermentation liquid, Bacillus licheniformis, polyacrylamide and potassium polyaspartate are transported to the silo by belt metering according to the mass ratio of 60:32:2:3:2:1 Extrusion granulation is carried out in the medium, and after granulation, the product is sieved to obtain the product of the present invention.

Embodiment 3

[0020] Soybean meal, decomposed animal manure, Bacillus subtilis, Bacillus megaterium, sodium polyacrylate, disodium ethylenediaminetetraacetic acid and aminotriacetic acid in a mass ratio of 20:70:2:3:1:2:1, passed The belt is metered and transported to the silo for extrusion and granulation. After the granulated product is screened, the product of the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com