Recovery method of rare earth metal electrolysis fused salt slag

A technology of rare earth metals and recycling methods, applied in the direction of improving process efficiency, etc., can solve problems such as high energy consumption, high cost, and difficulty in meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

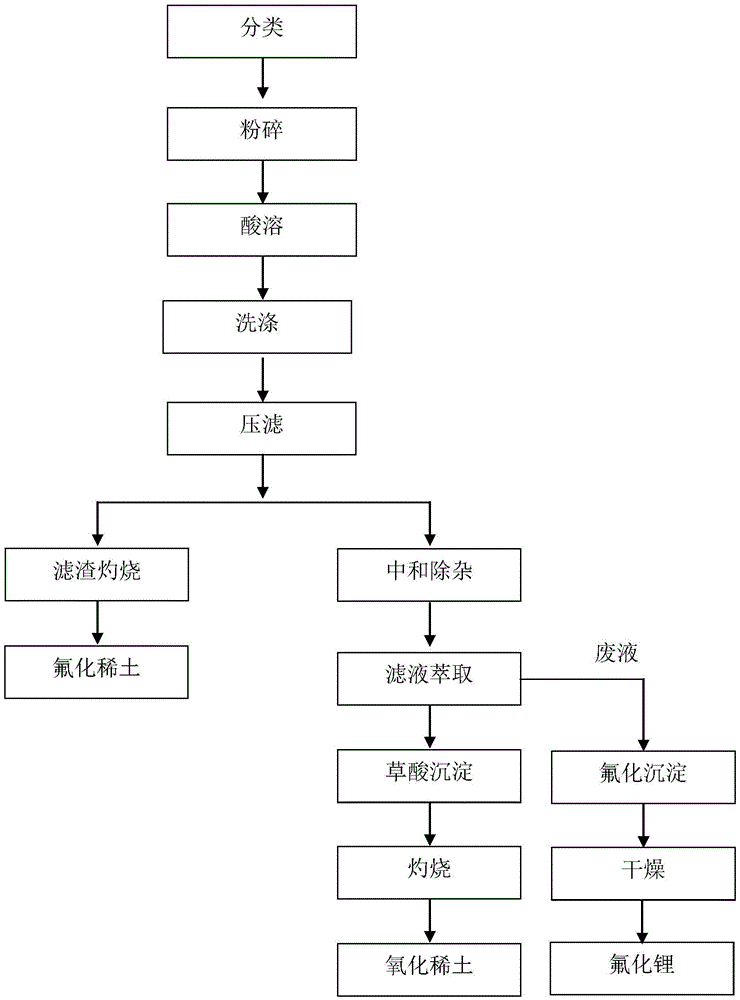

Method used

Image

Examples

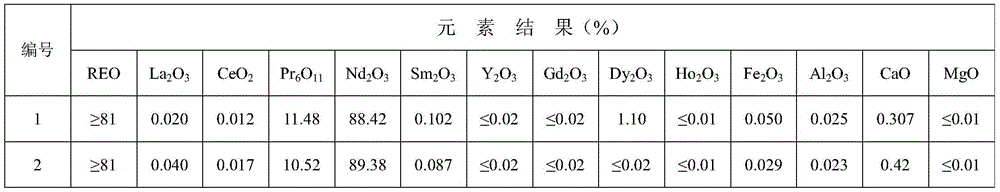

Embodiment 1

[0027] A method for recovering molten salt slag from rare earth metal electrolysis, using waste molten salt slag produced during electrolysis of rare earth molten salt in a fluoride system as a raw material, and proceeding according to the following steps:

[0028] (1) Classify the molten salt slag according to the content of impurities contained in the molten salt slag and the total amount of rare earth, and recycle the praseodymium neodymium and neodymium molten salt slag;

[0029] (2) The molten salt slag is pulverized, and then the ball mill is used to grind the slag material until the particle size reaches more than 100 mesh after the first break through the crusher, and it is set aside;

[0030] (3) Put the pulverized rare earth molten salt powder obtained in step 2 into the reaction tank, slowly add hydrochloric acid / nitric acid mixed acid solution with a volume ratio of 1:3 at a uniform speed, so that the acid solution is immersed in the powder, and the powder and The ...

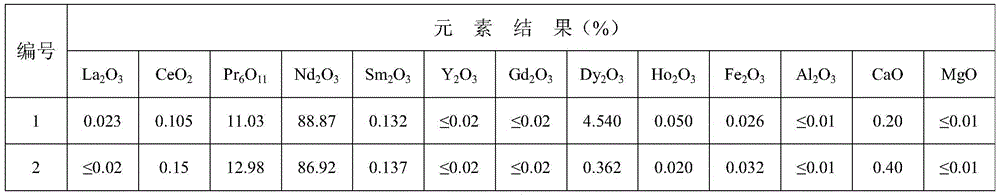

Embodiment 2

[0044] A method for recovering molten salt slag from rare earth metal electrolysis, using waste molten salt slag produced during electrolysis of rare earth molten salt in a fluoride system as a raw material, and proceeding according to the following steps:

[0045] (1) Classify the molten salt slag according to the content of impurities contained in the molten salt slag and the total amount of rare earth, and recycle the dysprosium-iron molten salt slag;

[0046] (2) The molten salt slag is pulverized, and then the ball mill is used to grind the slag material until the particle size reaches more than 100 mesh after the first break through the crusher, and it is set aside;

[0047] (3) Put the pulverized rare earth molten salt powder obtained in step 2 into the reaction tank, slowly add hydrochloric acid / nitric acid mixed acid solution with a volume ratio of 1:3 at a uniform speed, so that the acid solution is immersed in the powder, and the powder and The volume ratio of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com