A kind of copper-zinc composite oxide, its preparation method and application

A composite oxide and copper-zinc technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. Uniformity and other issues, to achieve the effect of environmental friendliness, high M2 selectivity, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A preparation method of copper-zinc composite oxide, comprising the steps of:

[0067] (1) At 20°C, configure a solution containing copper ions and zinc ions (n Cu2+ 4mmol and n Cu2+ :n Zn2+ =10:1) 50mL, the solvent is a pure aqueous solution, the copper ions are derived from copper nitrate, and the zinc ions are derived from zinc nitrate;

[0068] (2) prepare sodium carbonate solution (C Na2CO3 0.8mol / L) 50mL, it was added to the solution containing copper ions and zinc ions described in (1), stirred for 0.5h to obtain a suspension;

[0069] (3) Transfer the suspension to a 100mL polytetrafluoroethylene-lined autoclave, perform a hydrothermal reaction at 130°C for 18 hours, then cool naturally to 20°C to obtain a hydrothermal product;

[0070] (4) Filtrate the hydrothermal product, wash the obtained solid several times with deionized water and absolute ethanol, and then dry it at 60° C. for 12 hours;

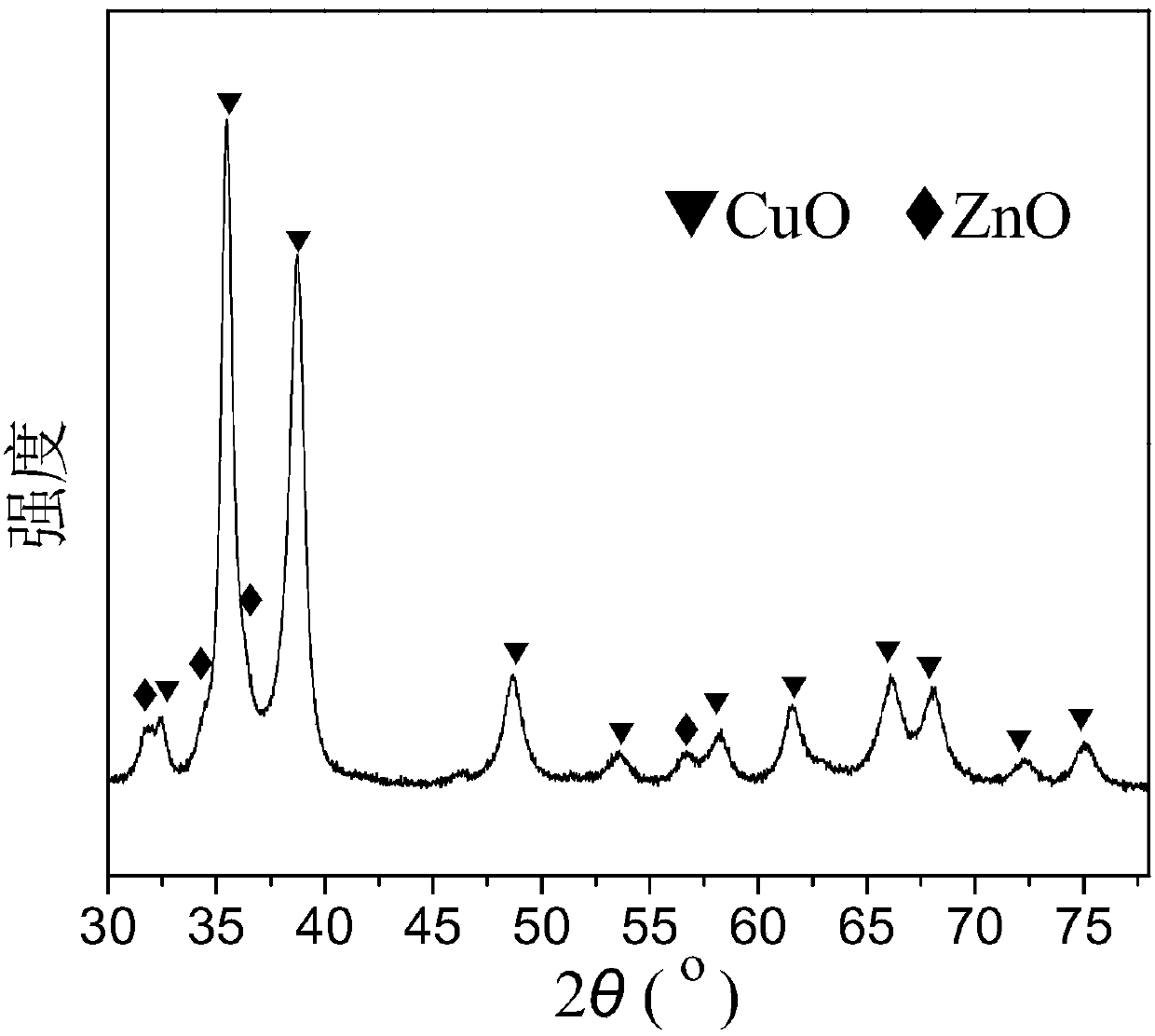

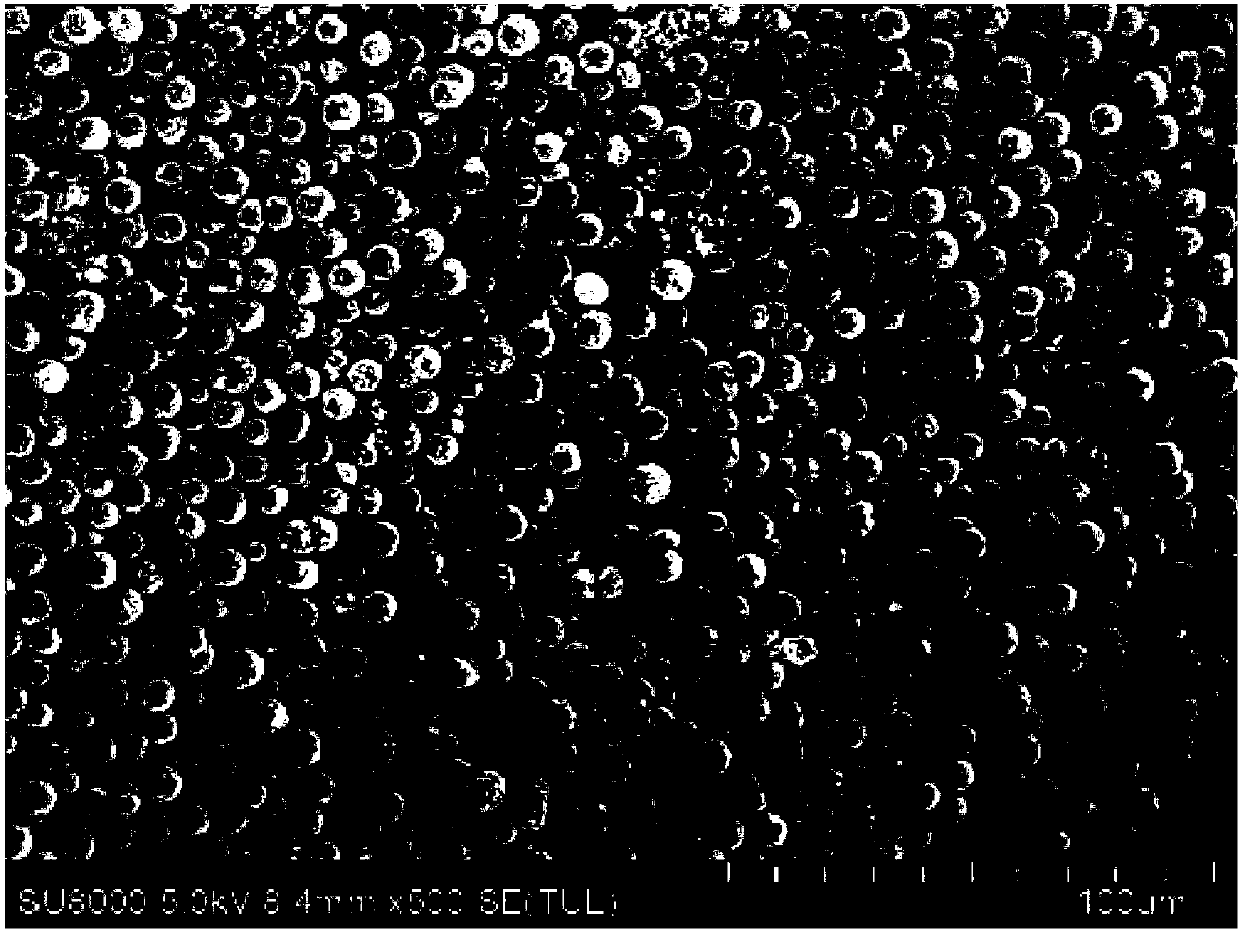

[0071] (5) Calcining the dried product at 400° C. for 12 hours...

Embodiment 2

[0076] A preparation method of copper-zinc composite oxide, comprising the steps of:

[0077] (1) At 25°C, configure a solution containing copper ions and zinc ions (n Cu2+ is 10mmol and n Cu2+ :n Zn2+ =5:1) 300mL, the solvent is a pure aqueous solution, the copper ions are derived from copper acetate, and the zinc ions are derived from zinc acetate;

[0078] (2) preparation potassium carbonate solution (C K2CO3 2mol / L) 50mL, it was added to the solution containing copper ions and zinc ions described in (1), stirred for 1.5h to obtain a suspension;

[0079](3) Transfer the suspension to a 600mL polytetrafluoroethylene-lined autoclave, perform a hydrothermal reaction at 100°C for 24 hours, then cool naturally to 20°C to obtain a hydrothermal product;

[0080] (4) Centrifuge the hydrothermal product, wash the obtained solid several times with deionized water and absolute ethanol, and then dry it at 80° C. for 10 h;

[0081] (5) Calcining the dried product at 500° C. for 10 ...

Embodiment 3

[0085] A preparation method of copper-zinc composite oxide, comprising the steps of:

[0086] (1) At 30°C, configure a solution containing copper ions and zinc ions (n Cu2+ is 50mmol and n Cu2+ :n Zn2+ =6:1) 200mL, solvent is aqueous ethanol (alcohol-water ratio is 0.4:1), copper ion is derived from copper chloride, and zinc ion is derived from zinc chloride;

[0087] (2) prepare sodium bicarbonate solution (C NaHCO3 1mol / L) 100mL, which was added to the solution containing copper ions and zinc ions described in (1), stirred for 2.5h to obtain a suspension;

[0088] (3) Transfer the suspension to a 500mL polytetrafluoroethylene-lined autoclave, perform a hydrothermal reaction at 150°C for 18 hours, then cool naturally to 20°C to obtain a hydrothermal product;

[0089] (4) Filtrate the hydrothermal product, wash the obtained solid several times with deionized water and absolute ethanol, and then dry it at 100°C for 8 hours;

[0090] (5) Calcining the dried product at 600° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com