High-temperature high-salinity oil reservoir polymer microsphere dispersed system modifying and flooding agent, and preparation method and application thereof

A dispersion system, high temperature and high salt technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of dispersion polymerization that has not been disclosed, and achieve the effect of improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

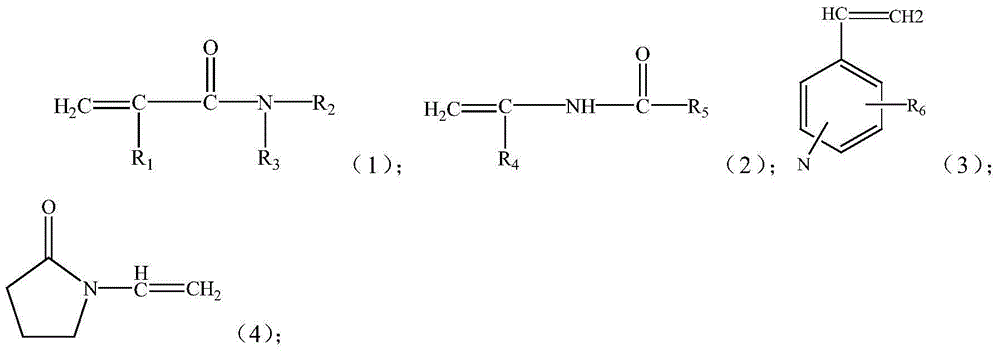

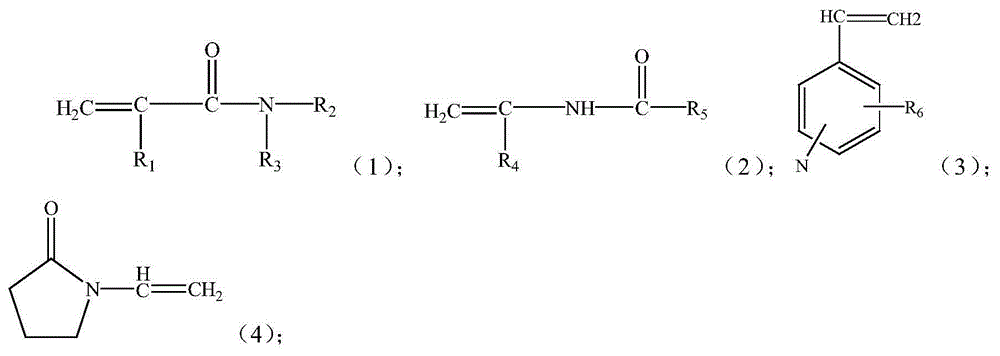

Method used

Image

Examples

Embodiment 1

[0047] First add 1000g of deionized water, 2.5g of methylenebisacrylamide (MBA), 0.3g of disodium ethylenediaminetetraacetic acid (EDTA), 2-acrylamido-2-methylpropanesulfonic acid (AMPS) into the container ) 125g, acrylamide (AM) 375g, sodium 2-acrylamidotetradecylsulfonate 5g, stir until completely mixed, neutralize with AMPS equimolar sodium hydroxide (NaOH) and adjust the pH to 7. Add 1,300 g of tert-butanol (TBA) and 250 g of polyethylene glycol (PEG) with a molecular weight of 20,000 and stir until completely mixed. Put this solution into the reaction kettle, and pass nitrogen gas for 30min. Turn on the stirring at 15°C, keep the rotation speed at 300rpm, and drop in 1.25% ammonium persulfate (APS) aqueous solution, 0.75% sodium bisulfite (MBS) aqueous solution and 2.5% 2,2'-even Nitrogen[2-(2-imidazolin-2-yl)propane] dihydrochloride (AIBA) aqueous solution 10g, and keep continuing nitrogen and stirring, stop nitrogen after 30min, raise the temperature to 30°C for 1h, I...

Embodiment 2

[0050] First add 1000g of deionized water, 2.2g of pentaerythritol triacrylate, 0.22g of disodium ethylenediamine tetraacetate (EDTA), 90g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), acryloyl Oxyethyltrimethylammonium chloride 30g, acrylamide (AM) 330g, octyl acrylate 4g, stir until completely mixed, neutralize with AMPS equimolar sodium hydroxide (NaOH) and adjust the pH to 6.5 , then add 775g of tert-butanol (TBA) and 25g of polyvinylpyrrolidone (PVP) of K30 and stir until completely mixed. Put this solution into the reaction kettle, and pass nitrogen gas for 30min. Turn on the stirring at 15°C, keep the rotation speed at 280rpm, and drop in 5.5% ammonium persulfate (APS) aqueous solution, 3.3% sodium bisulfite (MBS) aqueous solution and 11% 2,2'-even Nitrogen[2-(2-imidazolin-2-yl)propane] dihydrochloride (AIBA) aqueous solution 10g, and keep continuing nitrogen and stirring, stop nitrogen after 30min, raise the temperature to 30°C for 1h, It was then raised to 45...

Embodiment 3

[0053] First add 880g of deionized water, 3.2g of divinylbenzene, 0.28g of disodium ethylenediaminetetraacetic acid (EDTA), 80g of methacryloyloxyethyltrimethylammonium chloride, acrylamide (AM ) 480g, tert-butyl styrene 6g, stir until completely mixed evenly, neutralize with AMPS equimolar sodium hydroxide (NaOH) and adjust the pH to 5.5, then add tert-butanol (TBA) 1590g and the grade is 17-88 polyvinyl alcohol (PVA) 25g and stir until completely mixed. Put this solution into the reaction kettle, and pass nitrogen gas for 30min. Stirring is started at 30°C, the rotating speed is kept at 280rpm, 10 g of azobisisobutyronitrile (AIBN) ethanol solution with a concentration of 4% is added dropwise, and the nitrogen flow and stirring are continued, and the nitrogen flow is stopped after 30 minutes, and the temperature is raised to Raise to 55°C and keep for 3 hours, during which time it can be seen that the reaction solution gradually changes from transparent to translucent until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com