A production method for directly spinning hydrophilic and moisture-conducting polyester staple fibers

A polyester staple fiber and production method technology, which is applied in fiber processing, stretch spinning, fiber chemical characteristics, etc., can solve the problem of undefined continuous preparation method of hydrophilic polyester and polyester fiber that does not reflect moisture conduction and drainage Dryness, environmental or human injury and other problems, to achieve the effect of improving the hydrophilic and moisture-conducting effect, improving the spinnability, and reducing the thermal degradation of the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

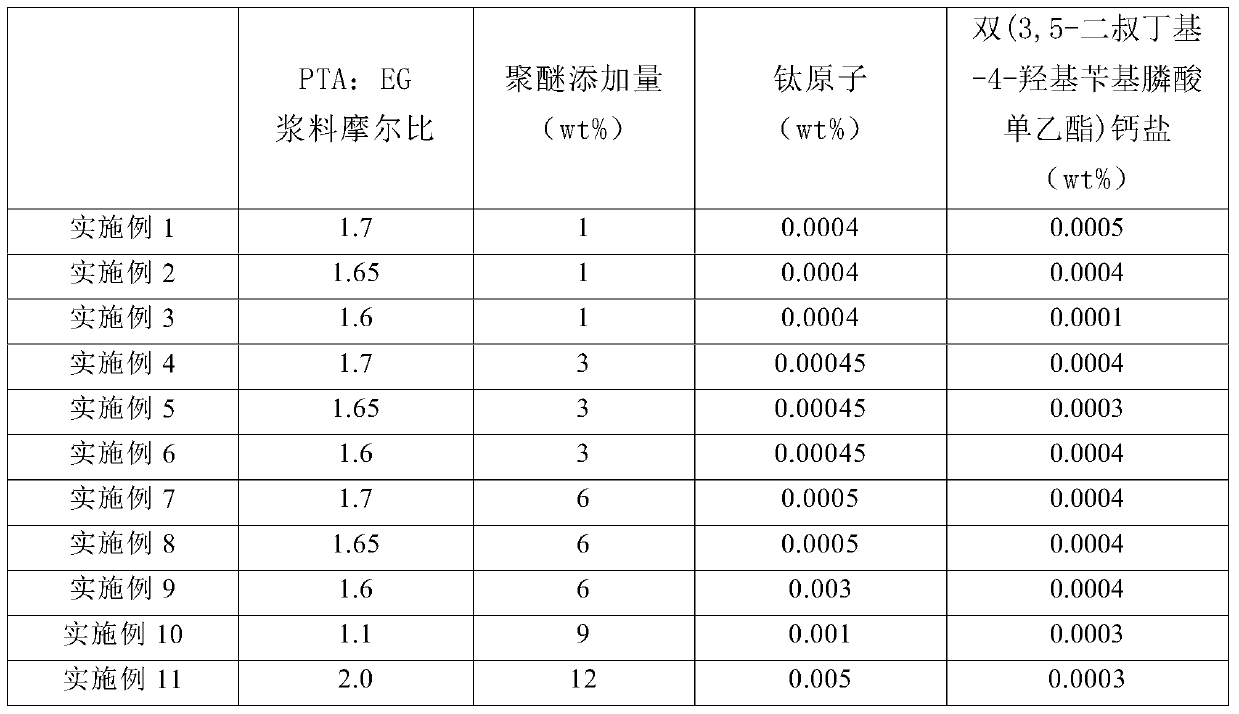

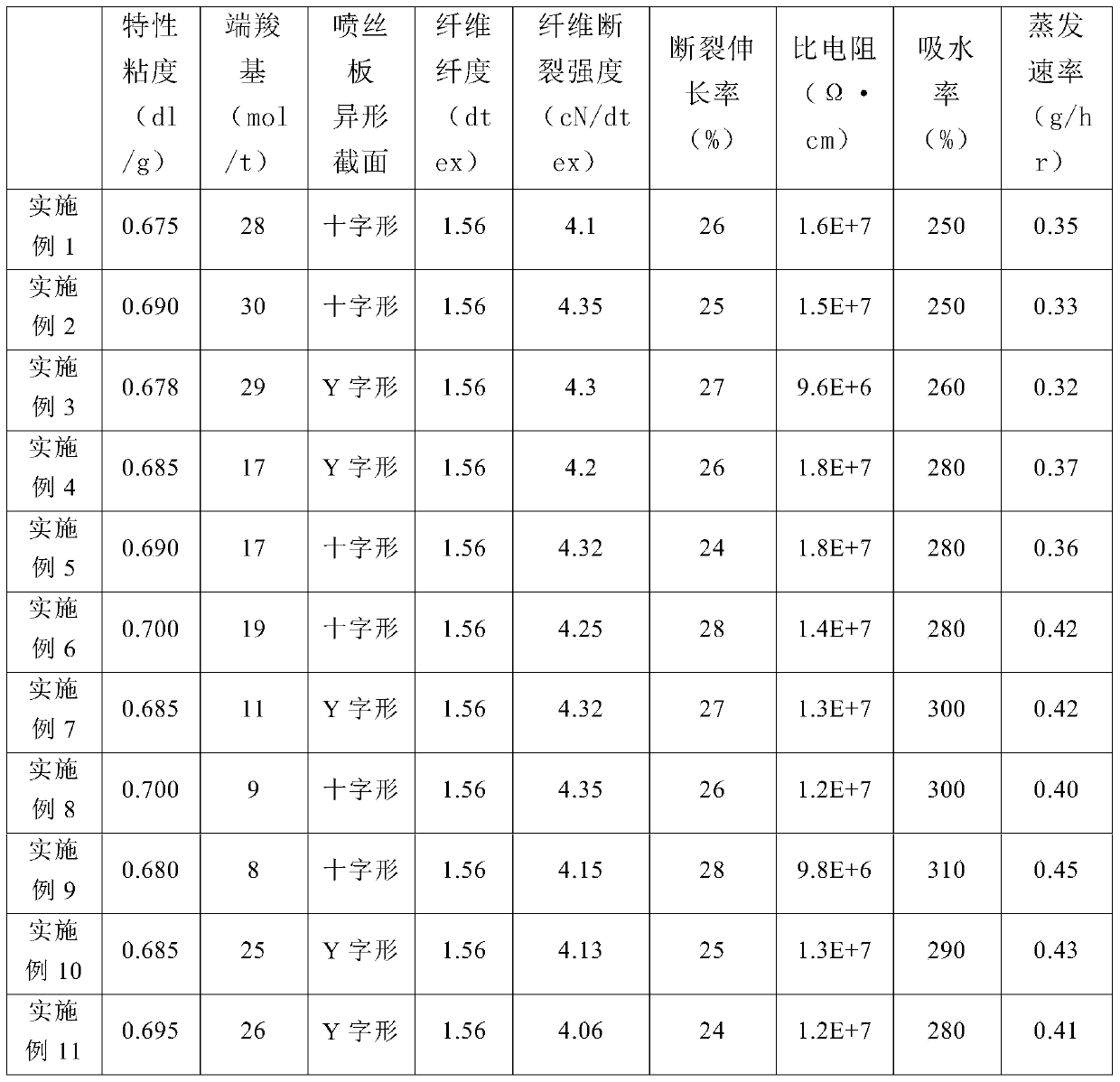

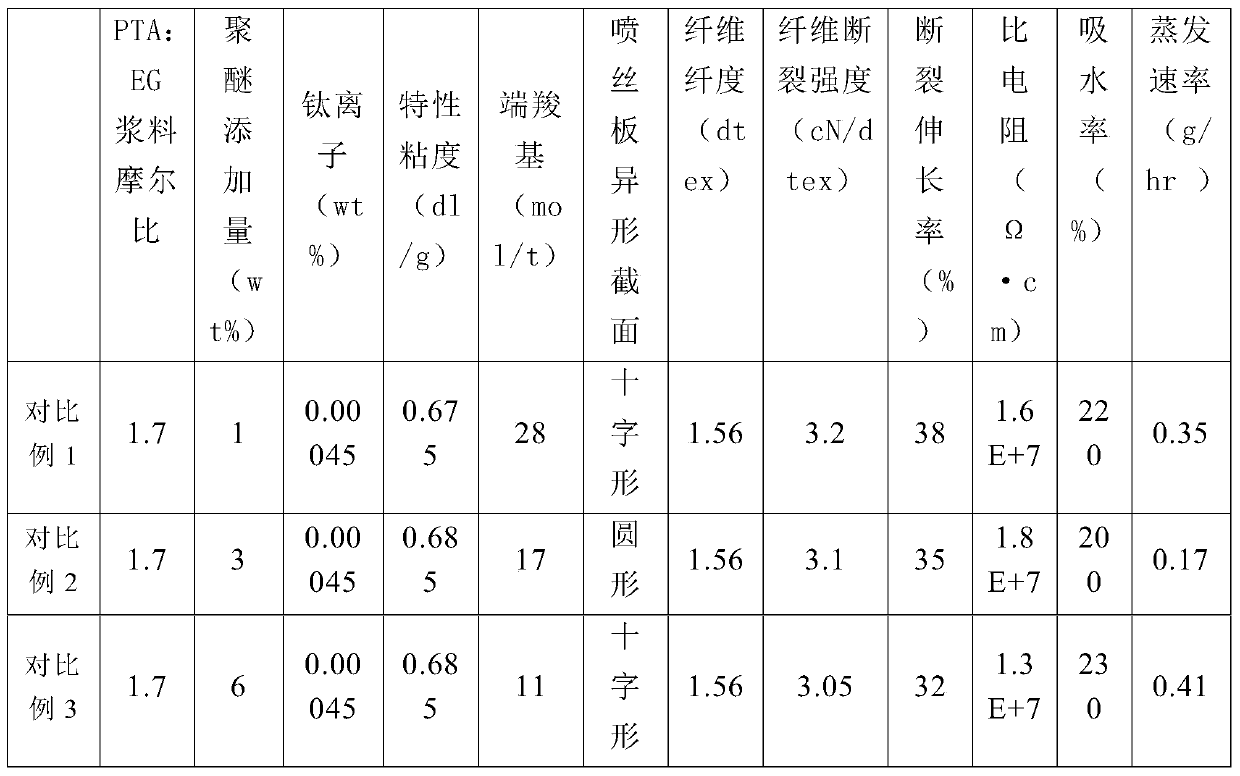

Examples

Embodiment

[0045] Raw materials terephthalic acid (PTA) and ethylene glycol (EG) are beaten according to the ratio; a 0.04wt% ethylene glycol titanium glycol solution is prepared and participates in slurry preparation.

[0046] The slurry is sent quantitatively and continuously into the horizontal agitated esterification reactor with a gear pump, and is stirred at a gauge pressure of 0.08-0.15MPa and a temperature of 255-265°C for esterification to produce an intermediate bishydroxyethyl terephthalate. When the esterification rate is 92-93%, the water generated during the esterification process is distilled out with ethylene glycol, and after the water is separated from the fractionating tower, 99wt% ethylene glycol is refluxed in the kettle, and the intermediate bishydroxyethyl terephthalate passes through The intermediate pipeline enters the pre-condensation reactor.

[0047] After polyethylene glycol with a molecular weight of 2000 enters the preparation area, additional ethylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com