Preparation method of highly-stable and cold water-soluble natural astaxanthin microcapsule preparation

A technology of natural astaxanthin and high stability, which is applied in the field of preparation of high-stability cold water-soluble natural astaxanthin microcapsule preparations, can solve problems such as poor transparency, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

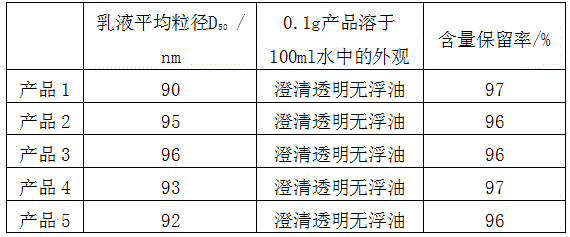

Examples

Embodiment 1

[0026] 1. Mix 30g of astaxanthin oil with a content of 10%, 3.0g of natural vitamin E, and 3.0g of polysorbate 80 at 55°C for 15 minutes until uniform to obtain an oil phase.

[0027] 2. Add 68g of gum arabic, 88g of sucrose, 4.0g of sodium ascorbate and 4.0g of tea polyphenols into 300g of purified water, stir at 75°C for 30 minutes until completely dissolved, adjust the pH value to 7.6, and obtain an aqueous phase.

[0028] 3. Add the oil phase at 55°C to the stirring water phase at 75°C, continue to stir for 30 minutes, then pass through the sand mill for 30 minutes, and the speed of the sand mill is 2200rpm, so that the particle size of the emulsion particles after grinding can reach 100nm Next, the obtained emulsion is granulated by spray cooling-starch fluidized bed drying method to obtain astaxanthin microcapsules. The spray drying conditions are: the inlet air temperature is 40°C, and the starch fluidized bed blast temperature is 65°C.

Embodiment 2

[0030] 1. Mix 300g of 10% astaxanthin oil, 60g of rosemary extract, and 30g of sucrose fatty acid ester at 55°C for 15 minutes until uniform to obtain an oil phase.

[0031] 2. Add 660g of sodium starch octenyl succinate, 900g of glucose, 25g of sodium ascorbate and 25g of tea polyphenol into 2.5kg of purified water, stir at 75°C for 30 minutes until completely dissolved, and adjust the pH to 7.8 to obtain an aqueous phase.

[0032] 3. Add the oil phase at 55°C to the stirring water phase at 75°C, continue to stir for 30 minutes, then pass through the sand mill for 30 minutes, and the speed of the sand mill is 2000rpm, so that the particle size of the emulsion particles after grinding can reach 100nm Next, the obtained emulsion is granulated by cold spray-starch fluidized bed drying method to obtain astaxanthin microcapsules. The spray drying conditions are: the inlet air temperature is 45°C, and the starch fluidized bed blast temperature is 60°C.

Embodiment 3

[0034] 1. Mix 6kg of astaxanthin oil with a content of 10%, 3kg of natural vitamin E, and 1.2kg of polyglycerol fatty acid ester at 55°C for 30 minutes until uniform to obtain an oil phase.

[0035] 2. Add 17.2kg of gum arabic, 12.0kg of isomalt, 0.3kg of sodium ascorbate and 0.3kg of citric acid into 40kg of purified water, stir at 75°C for 1 hour until completely dissolved, and adjust the pH value to 7.6 to obtain an aqueous phase.

[0036] 3. Add the oil phase at 55°C to the stirring water phase at 75°C, continue to stir for 30 minutes, then pass through the sand mill for 30 minutes, and the speed of the sand mill is 2100rpm, so that the particle size of the emulsion particles after grinding can reach 100nm Next, the obtained emulsion is granulated by cold spray-starch fluidized bed drying method to obtain astaxanthin microcapsules. The spray drying conditions are: the inlet air temperature is 40°C, and the starch fluidized bed blast temperature is 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com