Method for preparing magnetic-biochar-supported photocatalyst

A photocatalyst, biochar technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult catalyst recovery, unfavorable catalyst regeneration and reuse, etc., to increase the photocatalytic efficiency. , the effect of reducing churn and reducing churn loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (A) Preparation of magnetic biochar:

[0037] Wash 10.00g of rice roots, dry them, shred them, and place them in a crucible; carry out pre-carbonization treatment in a muffle furnace, in an air atmosphere, at a heating rate of 5°C / min, and heat up to 250°C for 4 hours at a constant temperature. Take it out after cooling to get 4.60g of the pre-carbonized sample; put the pre-carbonized sample into a porcelain boat, raise the temperature in a tube furnace with nitrogen protection (at a rate of 5°C / min), and heat it up to 700°C for 4 hours at a constant temperature , take out after natural cooling, and grind to obtain 2.30 g of magnetic biochar powder.

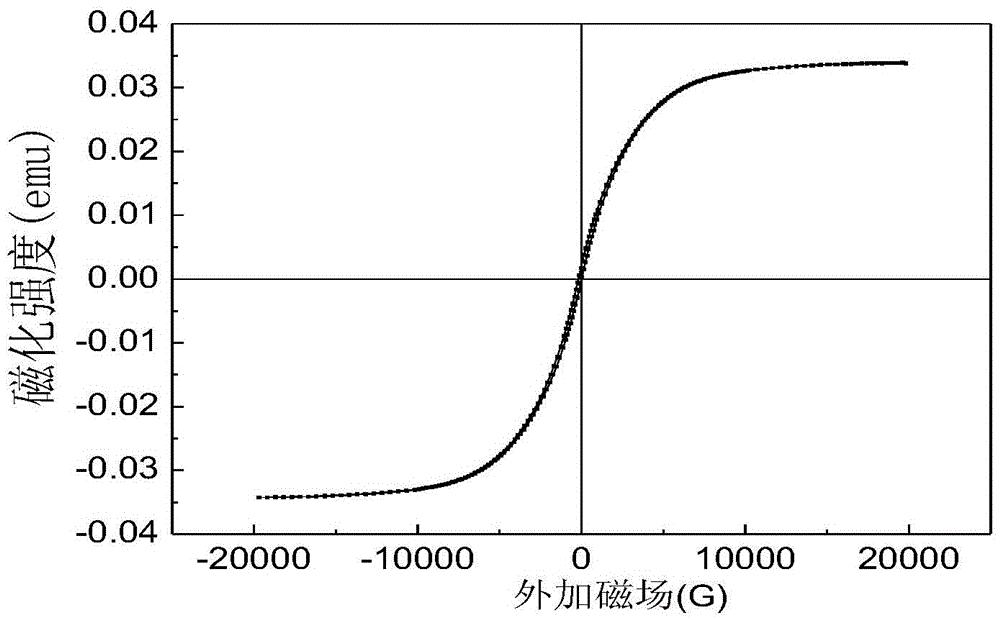

[0038] The hysteresis curve of the magnetic biochar powder calcined at 700℃ is as follows: figure 1 shown, from figure 1 It can be seen that the magnetic biochar powder is a kind of soft magnetic material.

[0039] (B) Preparation of photocatalyst precursor

[0040] Take 17mL of butyl titanate, add 11mL of absolute eth...

Embodiment 2

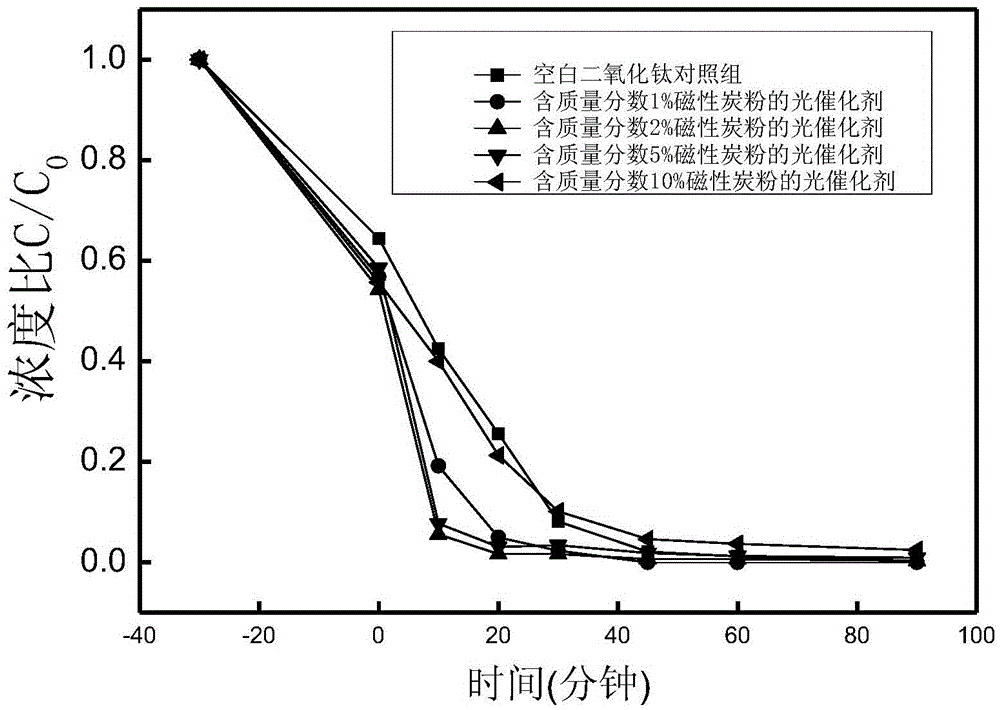

[0046] The photocatalyst containing 5% magnetic biochar with the best degradation effect was used for repeated performance tests to degrade the simulated pollutant Active Brilliant Red X-3B.

[0047] Take 5ml of the reactive brilliant red dye stock solution prepared in advance in a 250mL volumetric flask, add deionized water to dilute to a constant volume, and obtain a dye solution with a concentration of 20mg / L. Transfer the solution to a 500ml beaker, add 0.25g catalyst, put it into a constant temperature water tank, stir it mechanically for 30min until the adsorption equilibrium, turn on the light source, and start photocatalytic degradation. Samples were taken at 10min, 20min, 30min, 45min, 60min, and 90min after the start of illumination, and the supernatant was taken after centrifugation (10000rpm, 10min), and the ultraviolet absorption spectrum was measured at 536nm, and compared with the standard curve, the concentration of the dye solution after illumination was calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com