Composite film with photothermal conversion and heat energy storage/release functions and preparation method thereof

A composite film, photothermal conversion technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of high packaging requirements, low photothermal conversion efficiency, easy leakage, etc., to achieve a small temperature change range, photothermal Low conversion efficiency, preventing leakage and aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the composite film with functions of light-to-heat conversion and thermal energy storage and release uses polyvinyl alcohol as the main material of the film, gold nanoparticles as the light-to-heat conversion material, self-assembled and filled with organic phase change materials and evaporated water solvent, wherein the solid content of the organic phase change material PEG2000 is 5%.

[0035] In this example, the composite film with the functions of light-to-heat conversion and thermal energy storage and release is prepared according to the following method:

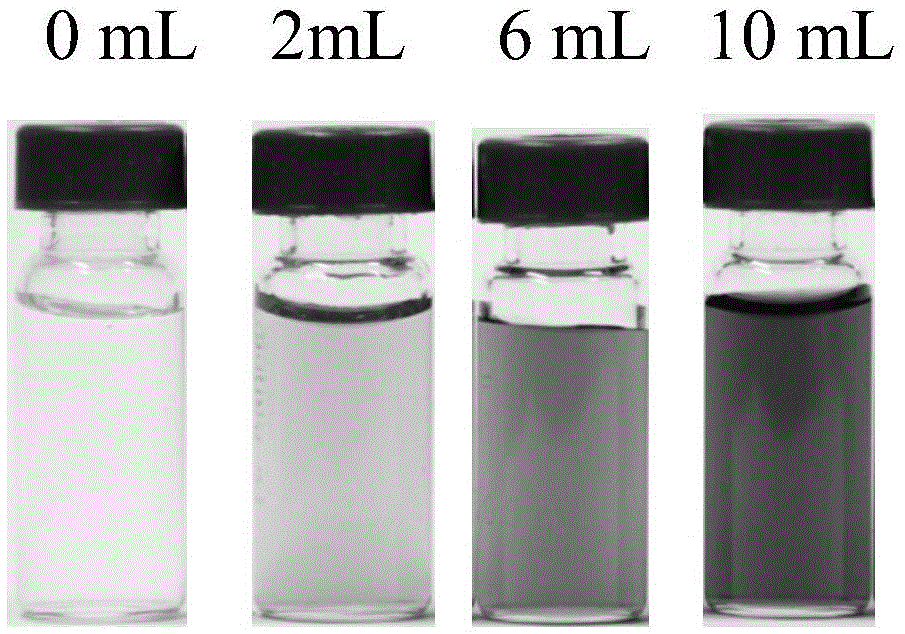

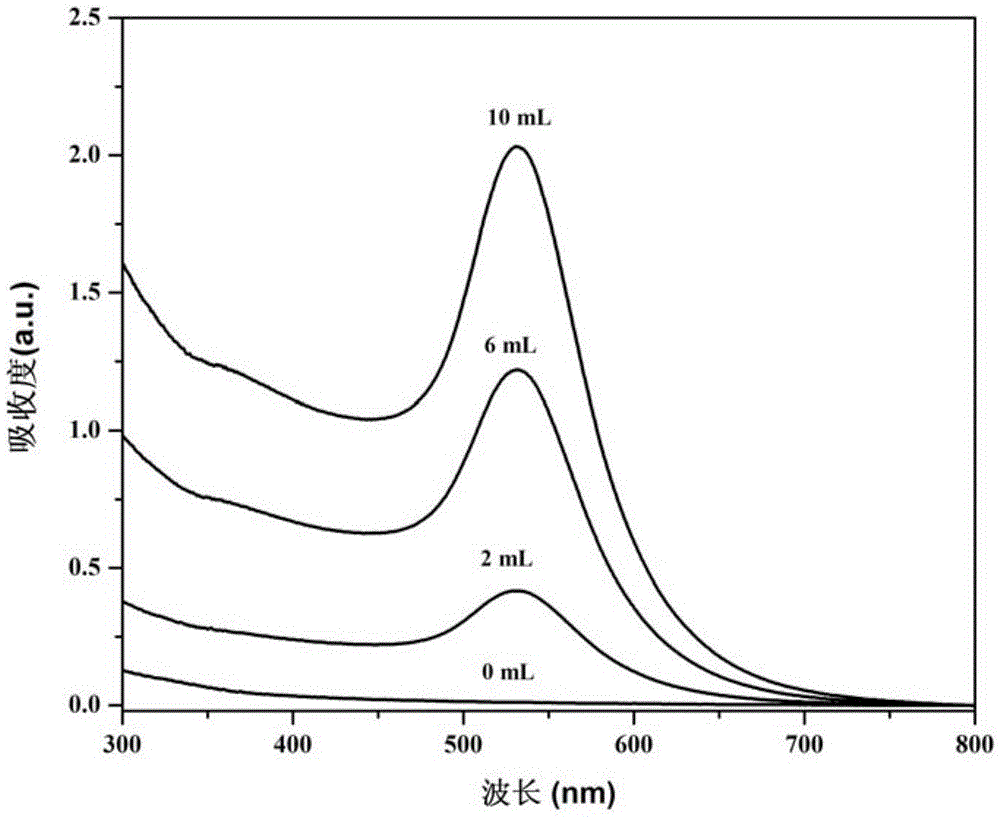

[0036] a. Preparation of gold nanoparticles

[0037] Add 1.25mL of 0.1M chloroauric acid aqueous solution into 50mL of ultrapure water, stir and heat to boiling, then add 750μL of 10% trisodium citrate aqueous solution, continue to reflux at 95°C for 0.5 hours, stop Stir and cool to room temperature to obtain a gold nanoparticle solution, which is stored in a refrigerator at 4°C for later use;...

Embodiment 2

[0047] The preparation method of the composite film of this embodiment is the same as that of Example 1, the amount of the added nano-gold particle solution is 10mL, the difference is that the added organic phase change material is 3.33mL of PEG2000 aqueous solution with a mass fraction of 20%. The solid content of PEG2000 in the obtained film was 40%.

[0048] After testing, when PEG2000 is used as the organic phase change material in Examples 1 and 2, the phase transition temperature of the obtained composite film is about 51-55°C.

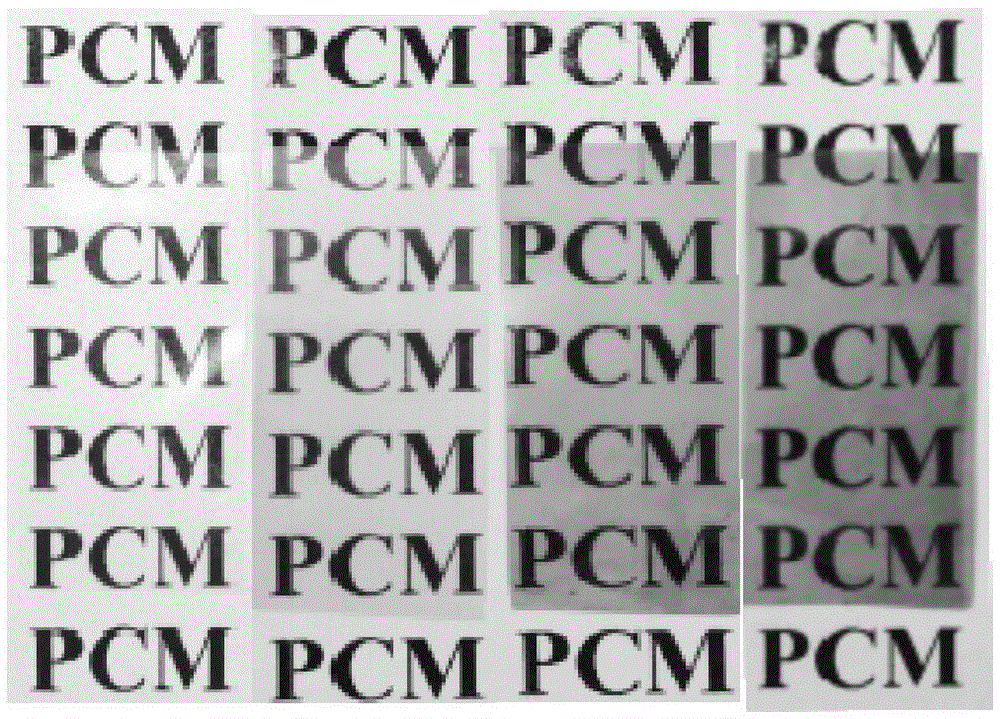

[0049] Figure 4 It is an optical photo of the composite film prepared in this embodiment to prevent leakage. The upper figure is the original PEG2000 material, and the lower figure is the composite phase change energy storage material (PEG / PVA / Au) prepared in this embodiment. It can be seen from the figure , when the temperature of the hot stage gradually increased from 20°C to 80°C, the original PEG2000 material gradually melted and leaked, t...

Embodiment 3

[0053] The preparation method of this example is the same as that of Example 1, the amount of the added nano-gold particle solution is 10mL, the difference is that the organic phase change material is PEG1000, the addition amount is 2.63mL of PEG1000 aqueous solution with a mass fraction of 2%, and the mass fraction is 5.55mL of 2% PEG1000 aqueous solution, 1.25mL of 20% PEG1000 aqueous solution by mass fraction, 3.33mL of 20% PEG1000 aqueous solution by mass fraction, the solid content of PEG1000 in the obtained composite phase change material is 5%, 10%, 20% respectively and 40%. After testing, when PEG1000 is used as the organic phase change material in this embodiment, the phase transition temperature of the obtained composite film is about 35-40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com