Preparation method and application of N-P-dopted carbon fiber/graphene/bacterial cellulose conducting film material

A bacterial cellulose and flexible electrode technology, applied in the preparation and application of nitrogen and phosphorus doped carbon fiber/graphene/bacterial cellulose flexible electrode materials, can solve the problem that flexible electrode materials do not have stability, cycle performance and mechanical properties and other issues, to achieve the effects of increased cycle performance, abundant resources, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

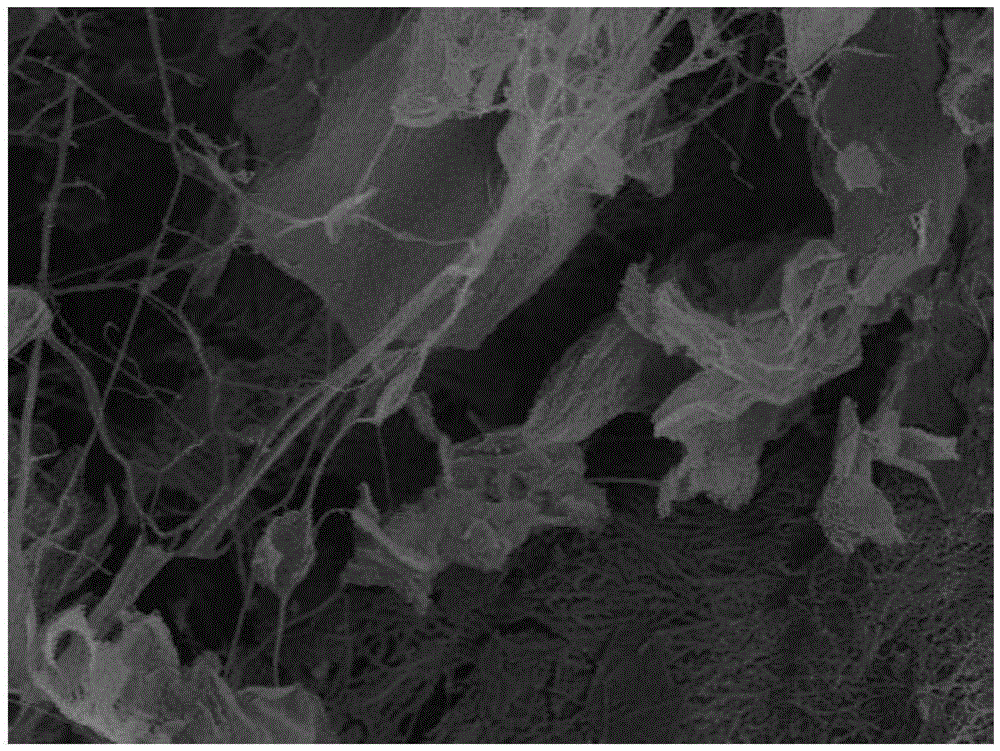

[0024] Embodiment 1: In this embodiment, a method for preparing a nitrogen-phosphorus-doped carbon fiber / graphene / bacterial cellulose flexible electrode material is performed according to the following steps:

[0025] 1. Soak the bacterial cellulose in deionized water for ultrasonic washing, then evenly disperse it in deionized water, and then transfer it to a homogenizer for high-speed stirring to obtain bacterial cellulose slurry for substrate;

[0026] 2. Another bacterial cellulose is soaked in deionized water for ultrasonic washing, freeze-dried to obtain dry bacterial cellulose; the dried bacterial cellulose is soaked in a dopant solution, ultrasonically treated after stirring, and then freeze-dried to obtain bacteria Cellulose precursor, the bacterial cellulose precursor is placed in a tube furnace for pyrolysis and carbonization to obtain carbon fibers doped with nitrogen and phosphorus; wherein the dopant solution is a mixed solution of urea and ammonium dihydrogen pho...

specific Embodiment approach 2

[0037] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the power of the ultrasonic wave is 1000w, and the frequency is 30KHz. Others are the same as the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the condition of the ultrasonic washing in step 1 is an ultrasonic time of 1-10 hours. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com