High-throughput high-retention rate composite nanofiltration membrane preparation method

A technology of composite nanofiltration membrane and rejection rate, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of active layer thickness, small flux, low rejection rate, etc., and achieve easy operation and process Simple and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a composite nanofiltration membrane with high throughput and high rejection rate, comprising the steps of:

[0040] (1) Preparation of cross-linked porous support membrane: mix polyetherimide and N-methylpyrrolidone that have been dried at 60°C for 12h in advance so that the mass concentration of polyetherimide is 19%, and stir at 60°C 12h, stand still for 10h to defoam, get the casting solution, pour the casting solution on the polypropylene non-woven fabric, scrape the film, make the thickness of the film 100μm, get a wet film, after 0s volatilization, transfer the wet film to 25℃ Soak in water for 5 minutes, take it out to obtain a base film of polyetherimide support layer, immerse it in an aqueous solution of ethylenediamine with a concentration of 3g / L to carry out cross-linking reaction for 0.5h, take it out and rinse it with deionized water, and blot dry the surface moisture to obtain a cross-linked porous support membrane;

[0041] (2) Pr...

Embodiment 2

[0044] A method for preparing a composite nanofiltration membrane with high throughput and high rejection rate, comprising the steps of:

[0045] (1) Preparation of cross-linked porous support membrane: mix polyetherimide and N, N-dimethylformamide which have been dried at 100° C. for 12 h in advance, so that the mass concentration of polyetherimide is 22%, Stir at 90°C for 6 hours, let it stand for 6 hours to defoam, and get the casting solution. Pour the casting solution on the polysulfone non-woven fabric, scrape the film to make the thickness of the film 300 μm, and volatilize for 10 seconds to get a wet film. Transfer to water at 50°C, soak for 120min, take it out to obtain a base film of polyetherimide support layer, immerse in ethylenediamine methanol solution with a concentration of 120g / L for cross-linking reaction for 5h, take it out and rinse it with deionized water, and Blot the moisture on the surface to obtain a cross-linked porous support membrane;

[0046] (2)...

Embodiment 3

[0049] A method for preparing a composite nanofiltration membrane with high throughput and high rejection rate, comprising the steps of:

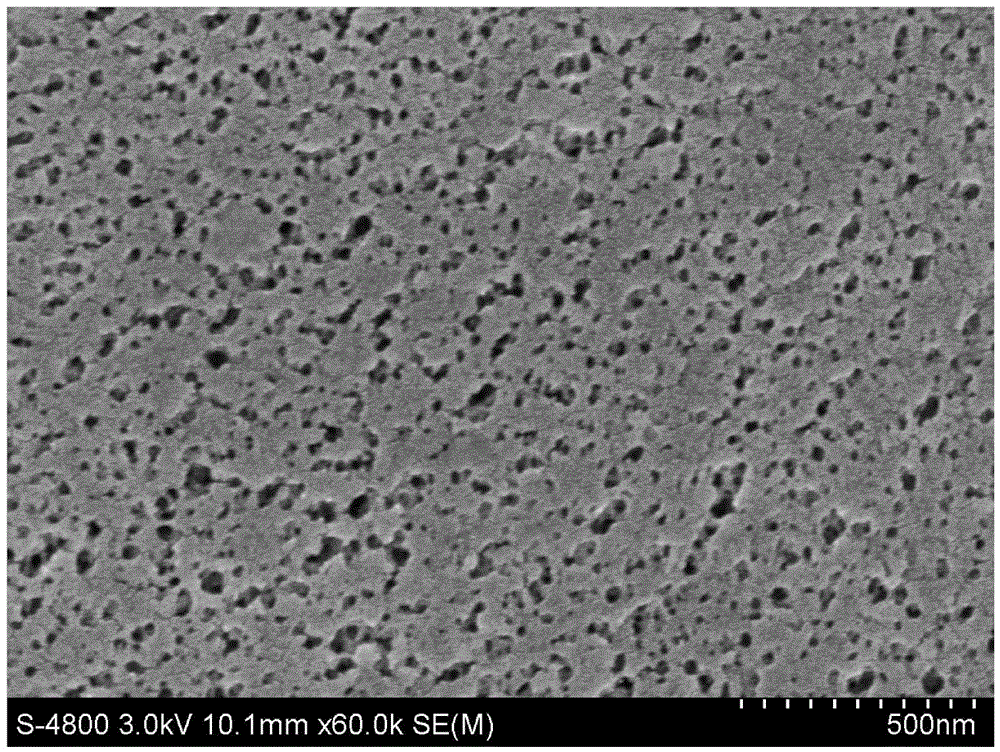

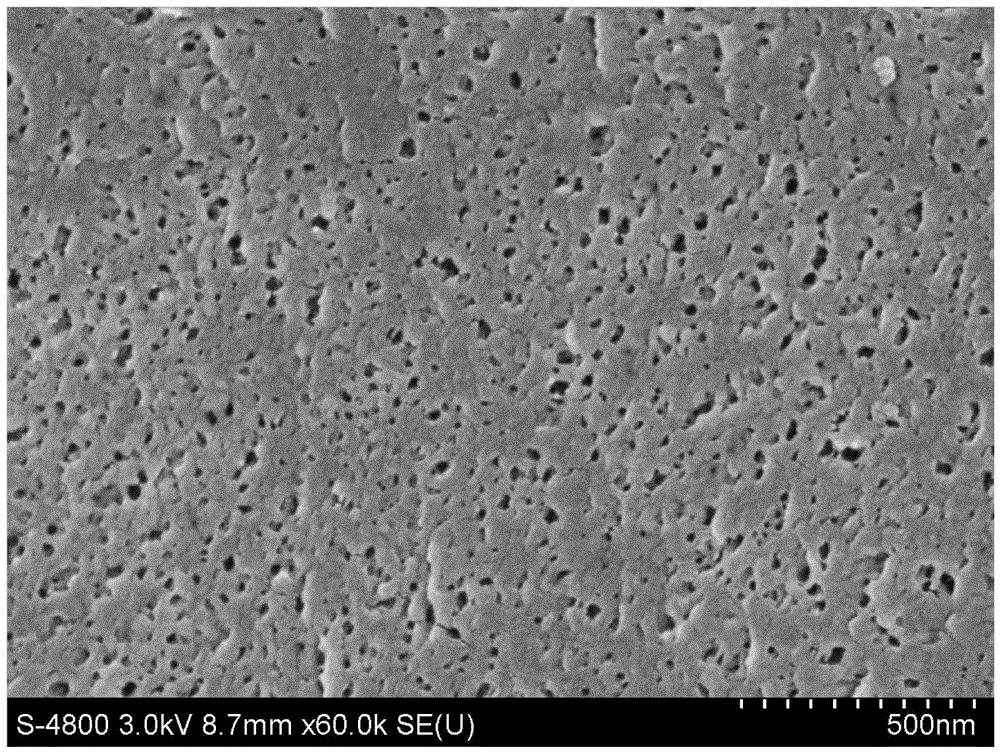

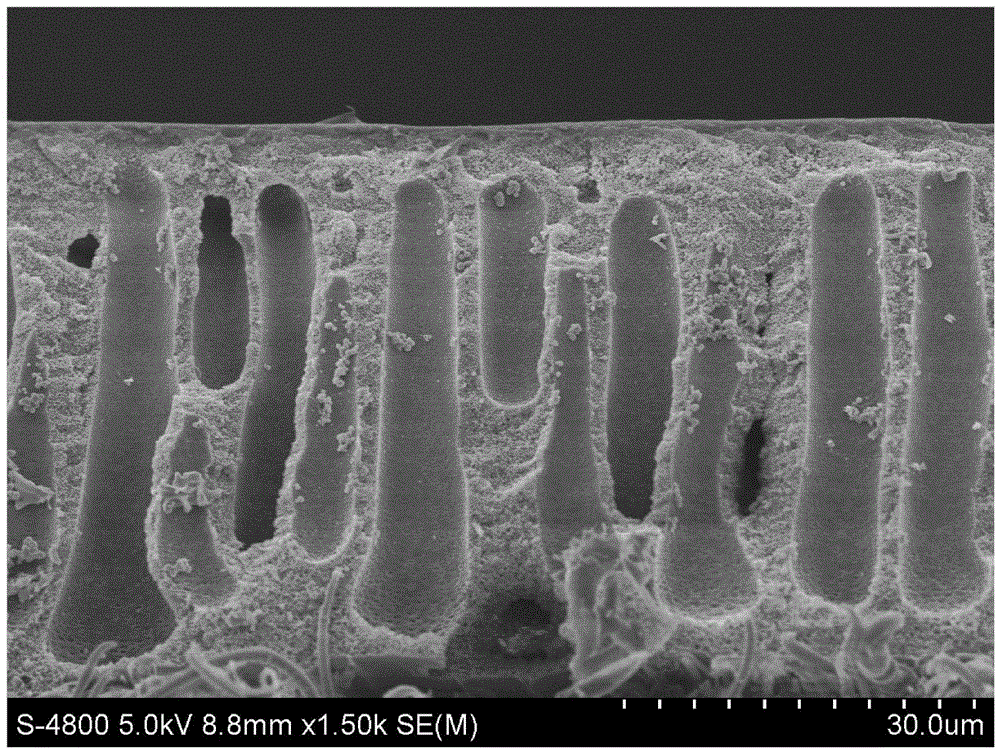

[0050] (1) Preparation of a cross-linked porous support membrane: mix polyetherimide and N, N-dimethylacetamide which have been dried at 100° C. for 8 hours, so that the mass concentration of polyetherimide is 22%, Stir at 60°C for 6 hours, stand still for 14 hours to defoam, and obtain the casting solution. Pour the casting solution on the polyester non-woven fabric, scrape the film to make the thickness of the film 300 μm, and volatilize for 60 seconds to obtain a wet film. Transfer to 25 ℃ water, soak 60min, take out, obtain polyetherimide supporting layer base film (the surface structure of base film sees figure 1 ), immersed in a concentration of ethylenediamine isopropanol solution of 60g / L to carry out cross-linking reaction 5h, take out and rinse with deionized water, and blot the moisture on the surface to obtain a cross-linked por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com