Scale-inhibiting corrosion inhibitor composition, scale-inhibiting corrosion inhibitor, and applications of scale-inhibiting corrosion inhibitor

A technology of scale and corrosion inhibitor and composition, which is applied in descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc. and corrosion inhibition function, microorganisms and slime hazards, etc., to achieve the effect of reducing processing costs and daily maintenance workload, reducing bacterial corrosion and bacterial algae growth problems, and reducing secondary pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0045] This preparation example was used to synthesize the Mannich base used in the example.

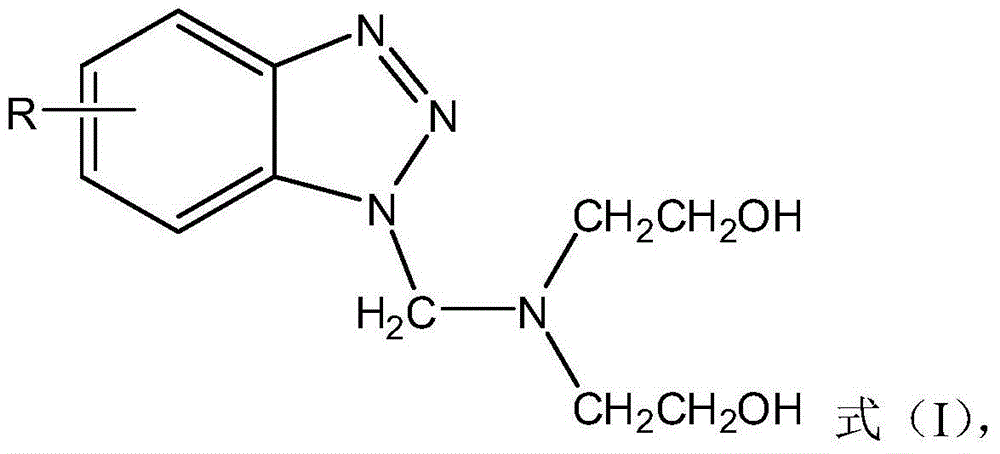

[0046] In a 250ml four-neck flask equipped with a thermometer, a stirrer, a reflux condenser and a dropping funnel, add 0.1mol (11.9g) benzotriazole (AR), 0.1mol (14.15g) diethanolamine hydrochloride ( AR), 100ml of distilled water, heated to reflux, dripped 0.1mol (8.1g of 37% aqueous solution) formaldehyde solution (AR) under reflux conditions, refluxed for 5 hours after dripping, and then cooled to obtain a light yellow solution, concentrated and cooled to obtain a light yellow Crystallized and dried to obtain 1-[N,N'-bis(2-hydroxyethyl)aminomethyl]benzotriazole (R is hydrogen, referred to as product-1).

[0047] According to the above steps, benzotriazole was replaced with methylbenzotriazole to obtain 1-[N,N'-bis(2-hydroxyethyl)aminomethyl]methylbenzotriazole (R is Methyl, referred to as product-2).

[0048] According to the above procedure, replace benzotriazole with n-butylb...

Embodiment 1

[0050] Weigh 1.0g of product-1, then add 7.78g of AA / AMPS, 7.0g of PAA, 2.0g of anhydrous zinc chloride, and finally dilute with water to form a 30% by weight pharmaceutical solution, and stir evenly.

Embodiment 2

[0052] Weigh 2.0g of product-2, then add 8.88g of AA / SMAM, 8.0g of PMA, 1.0g of anhydrous zinc chloride, and finally dilute with water to form a 30% by weight pharmaceutical solution, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com