Aftertreatment method for Sr2Si5N8: Eu<2+> fluorescent powder

A fluorescent powder and powder technology, which is applied in the field of luminescent materials, can solve the problems of reduced luminous efficiency and poor moisture resistance of fluorescent powder, and achieve the effects of increasing luminous intensity, improving photoluminescence efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

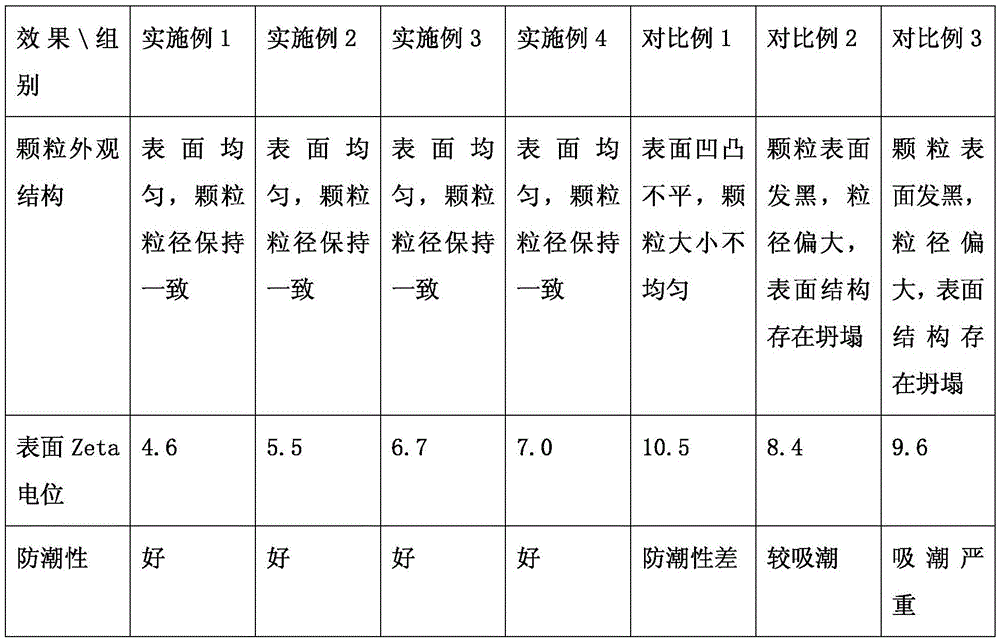

Examples

Embodiment 1

[0032]Embodiment 1 A kind of Sr 2 Si 5 N 8 : Eu 2+ The aftertreatment method of fluorescent powder comprises the following steps:

[0033] (1) Pickling treatment: prepare a nitric acid solution with a concentration of 0.5mol / L, take phosphor powder and disperse it evenly in the nitric acid solution to prepare a phosphor powder suspension with a concentration of 50%, centrifuge after stirring at room temperature, and then separate the Phosphor powder was washed to pH 7.0.

[0034] (2) Surfactant solution treatment: add the fluorescent powder obtained in step (1) to 1mol / L sodium lauryl sulfate solution, prepare a fluorescent powder suspension with a concentration of 35%, centrifuge after stirring at room temperature separate.

[0035] (3) Coating treatment: mix absolute ethanol, fluorescent powder and tetraamine silicon alkoxide evenly, prepare a suspension with a concentration of 60%, and drop into the fluorescent powder suspension while stirring 8% deionized water, afte...

Embodiment 2

[0037] Embodiment 2 A kind of Sr 2 Si 5 N 8 : Eu 2+ The aftertreatment method of fluorescent powder comprises the following steps:

[0038] (1) Pickling treatment: prepare a hydrochloric acid solution with a concentration of 5mol / L, take phosphor powder and disperse it evenly in the hydrochloric acid solution to prepare a phosphor powder suspension with a concentration of 50%, centrifuge after stirring at room temperature, and then separate the phosphor powder Powder wash to pH 7.1.

[0039] (2) Surfactant solution treatment: the fluorescent powder obtained in step (1) is added to 1mol / L sodium dodecylbenzene sulfate solution, and it is prepared into a fluorescent powder suspension with a concentration of 40%, after stirring at room temperature Centrifuge.

[0040] (3) Coating treatment: mix methanol, fluorescent powder and tetraamine titanium alkoxide evenly, prepare a suspension with a concentration of 50%, and drop 10% of the weight of the fluorescent powder into the f...

Embodiment 3

[0042] Embodiment 3 A kind of Sr 2 Si 5 N 8 : Eu 2+ The aftertreatment method of fluorescent powder comprises the following steps:

[0043] (1) Pickling treatment: prepare a sulfuric acid solution with a concentration of 2mol / L, take the fluorescent powder and evenly disperse it in the sulfuric acid solution to prepare a fluorescent powder suspension with a concentration of 45%, centrifuge after stirring at room temperature, and then separate the fluorescent powder Powder wash to pH 7.2.

[0044] (2) Surfactant solution treatment: add the fluorescent powder obtained in step (1) into 0.8mol / L triethanolamine stearate solution, prepare a fluorescent powder suspension with a concentration of 35%, centrifuge after stirring at room temperature separate.

[0045] (3) Coating treatment: mix acetone, fluorescent powder and tetraamine zirconium alkoxide evenly, prepare a suspension with a concentration of 45%, and drop 7% of the fluorescent powder into the fluorescent powder suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com