A kind of resource treatment method of antibiotic bacteria residue

A technology of antibiotic bacteria residue and treatment method, which is applied in the direction of solid waste removal, etc., can solve the problems of landfill method occupying large land resources, high cost of incineration method, and a large amount of harmful gas, so as to achieve harmlessness and resource utilization, Reliable process technical parameters and the effect of eliminating drug residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

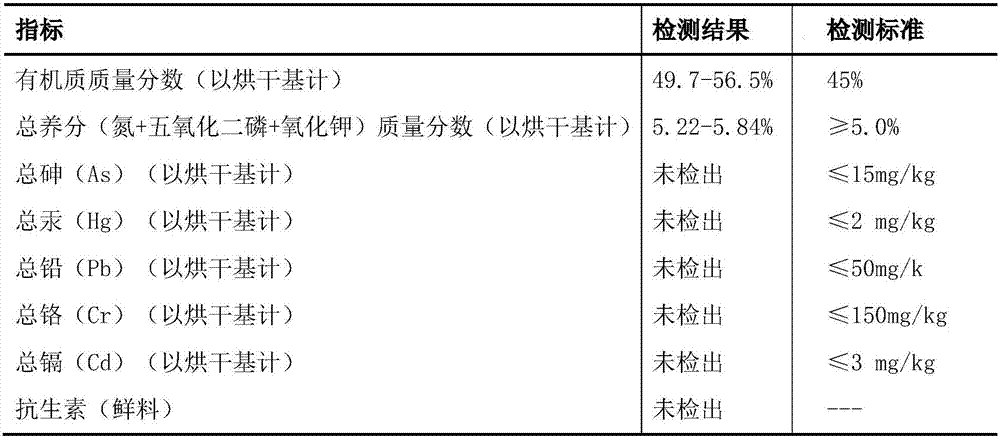

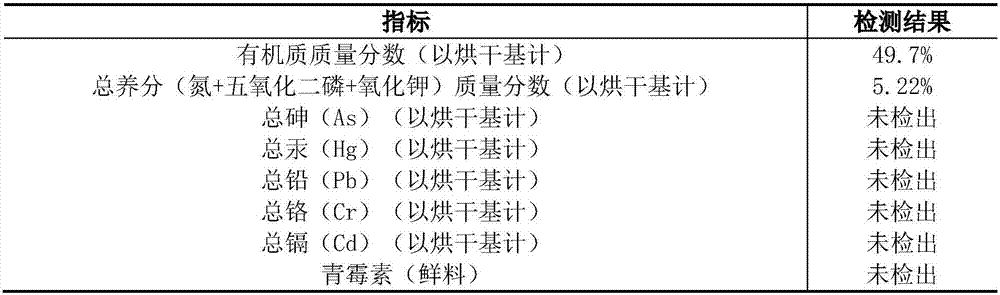

Embodiment 1

[0040] The resource processing of embodiment 1 penicillin scum:

[0041]Place the penicillin slag in the autoclave, first pass high-pressure steam flash for 8 minutes, cool naturally to 100°C, pass high-pressure steam flash for 12 minutes for the second time, and naturally cool to 80°C, steam temperature is 160°C, pressure It is 1200kPa, and the bacterial residue after two-stage steam flash evaporation is placed in the blending tank. According to the weight ratio of bacterial residue:penicillin process wastewater:potassium dihydrogen phosphate=250:5:1.5, stir for 10min, and adjust the pH value after mixing evenly After 6, the prepared liquid is obtained, and enters the acid-producing reactor, and the acid-producing reactor is inoculated with anaerobic digested sludge, the inoculation ratio is 40% by volume, the pH value is controlled at 6, the temperature is 30-40°C, and the hydraulic retention time is 30h; The effluent from the acid-producing reactor enters the methanogenic r...

Embodiment 2

[0045] The resource processing of embodiment 2 erythromycin scum:

[0046] Place the erythromycin residue in an autoclave, pass high-pressure steam for 5 minutes for the first time, and naturally cool to 100°C, pass high-pressure steam for 15 minutes for the second time, and naturally cool to 80°C, and the steam temperature is 150°C , the pressure is 1300kPa, the bacteria residue after two-stage steam flashing is placed in the deployment tank, according to the weight ratio of bacteria residue:penicillin process wastewater:potassium dihydrogen phosphate=230:6:2.5, stir for 10min, mix well and adjust the pH After the value is 6, the prepared solution is obtained, and enters the acid production reactor, and the acid production reactor is inoculated with anaerobic digested sludge, the inoculation ratio is 35% by volume, the pH value is controlled to be 6, the temperature is 30-40 °C, and the hydraulic retention time is 32h; the effluent from the acid-producing reactor enters the m...

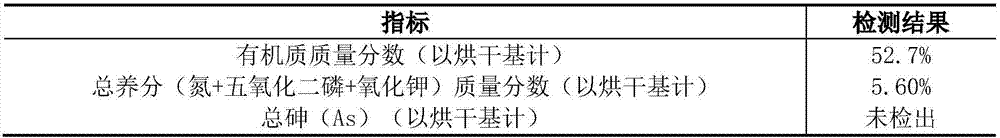

Embodiment 3

[0051] Embodiment 3 Recycling treatment of cephalosporin scum:

[0052] 4) In the dehydration section, the conditioner is a mixture of fly ash, bentonite and calcium oxide, and its mass ratio is fly ash: bentonite: calcium oxide = (1-2): (0.5-1): (0.1- 0.3).

[0053] Place the cephalosporin slag in the autoclave, pass high-pressure steam for 6 minutes for the first time, and naturally cool to 100°C, pass high-pressure steam for 12 minutes for the second time, and naturally cool to 80°C, and the steam temperature is 170°C , the pressure is 1400kPa, the bacteria residue after two-stage steam flashing is placed in the deployment tank, according to the weight ratio of bacteria residue:penicillin process wastewater:potassium dihydrogen phosphate=220:6:2.2, stir for 10min, mix well and then adjust the pH After the value is 6.5, the preparation solution is obtained, and enters the acid production reactor, and the acid production reactor is inoculated with anaerobic digested sludge, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com