Cationic silicon-containing acrylate fabric water repellent and preparation method thereof

A silicone acrylate and cationic technology, applied in textiles and papermaking, liquid-repellent fibers, fiber treatment, etc., can solve the problems of high viscosity of macromolecular silicone oil, unstable emulsion reaction, difficult emulsification and dispersion, etc., and achieve excellent Film-forming performance, water-repellent effect improvement, low-adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

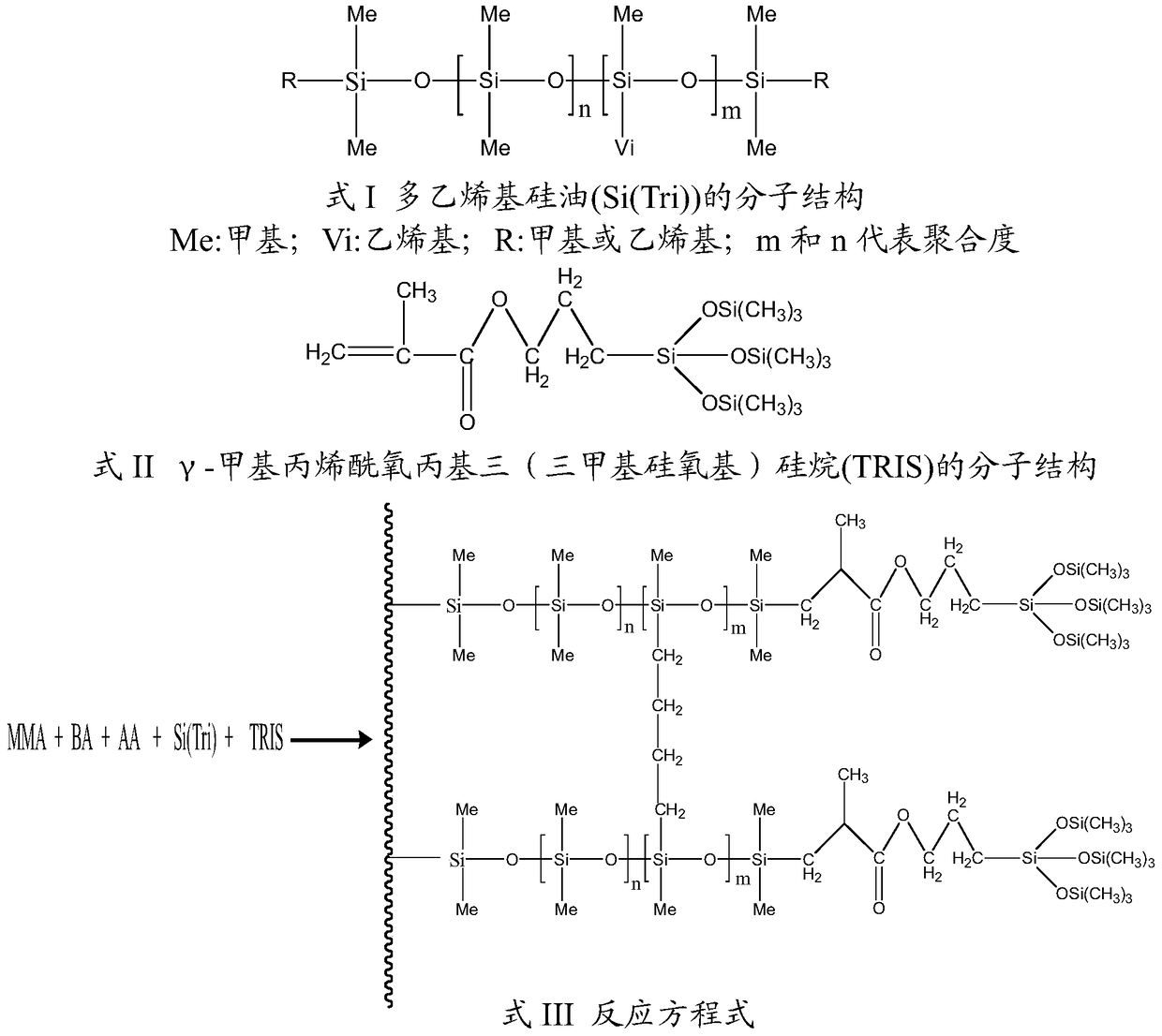

[0050] In this example, a cationic silicon-containing acrylate fabric water repellent is prepared from the following raw materials in parts by weight: 900 parts of acrylate mixed monomers, 100 parts of silicone monomers, 30 parts of emulsifiers, and 3 parts of initiators. parts, 30 parts of cross-linking agent, 4000 parts of deionized water;

[0051] The acrylate mixed monomer is methyl methacrylate (MMA), butyl acrylate (BA) and acrylic acid (AA) with a mass ratio of 5.0:5.0:0.15;

[0052] The organosilicon monomer is γ-methacryloxypropyl tris(trimethylsiloxy)silane (TRIS) and polyvinyl silicone oil (Si(Tri), viscosity 3000±500cst, vinyl content 10.0mol %), the mass ratio is 8.5:1.5;

[0053] The emulsifier is composed of octadecyl polyether acrylate trimethylammonium chloride (OATAC) and isomeric tridecyl alcohol polyoxyethylene ether (DNS500), and the mass ratio of the two is 1.2:0.3;

[0054] The initiator is azobisisobutylamidine hydrochloride (AIBA);

[0055] The cros...

Embodiment 2

[0067] In this example, a cationic silicon-containing acrylate fabric water repellent is prepared from the following raw materials in parts by weight: 800 parts of acrylate mixed monomer, 200 parts of silicone monomer, 40 parts of emulsifier, 4 parts of initiator parts, 23 parts of cross-linking agent, 3000 parts of deionized water;

[0068] The acrylate mixed monomer is methyl methacrylate (MMA), butyl acrylate (BA) and acrylic acid (AA) with a mass ratio of 6.5:3.5:0.25;

[0069] The organosilicon monomer is γ-methacryloxypropyl tris(trimethylsiloxy)silane (TRIS) and polyvinyl silicone oil (Si(Tri), viscosity 3000±500cst, vinyl content 10.0mol %), the mass ratio is 7.5:2.5;

[0070] The emulsifier is composed of octadecyl polyether acrylate trimethylammonium chloride (OATAC) and isomeric tridecyl alcohol polyoxyethylene ether (DNS500), and the mass ratio of the two is 1.0:0.4;

[0071] Described initiator is azobisisobutylimidazoline hydrochloride (AIBI);

[0072] The cro...

Embodiment 3

[0084] In this example, a cationic silicon-containing acrylate fabric water repellent is prepared from the following raw materials in parts by weight: 720 parts of acrylate mixed monomers, 280 parts of silicone monomers, 48.88 parts of emulsifiers, and 4.5 parts of initiators. parts, 18 parts of cross-linking agent, 2800 parts of deionized water;

[0085] The acrylate mixed monomer is methyl methacrylate (MMA), butyl acrylate (BA) and acrylic acid (AA) with a mass ratio of 7.5:2.5:0.30;

[0086] The organosilicon monomer is γ-methacryloxypropyl tris(trimethylsiloxy)silane (TRIS) and polyvinyl silicone oil (Si(Tri), viscosity 85000±6000cst, vinyl content 6.0mol %), the mass ratio is 6.5:3.5;

[0087] The emulsifier is composed of octadecyl polyether acrylate trimethylammonium chloride (OATAC) and isomeric tridecyl alcohol polyoxyethylene ether (DNS500), and the mass ratio of the two is 0.8:0.4;

[0088] The initiator is azobisisobutylamidine hydrochloride (AIBA);

[0089] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com