Waste color raw material powder and application thereof

A technology of waste and raw material powder, applied in the direction of multi-color effect coatings, etc., can solve problems such as waste pollution, achieve the effects of good coating film quality, wide application space, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

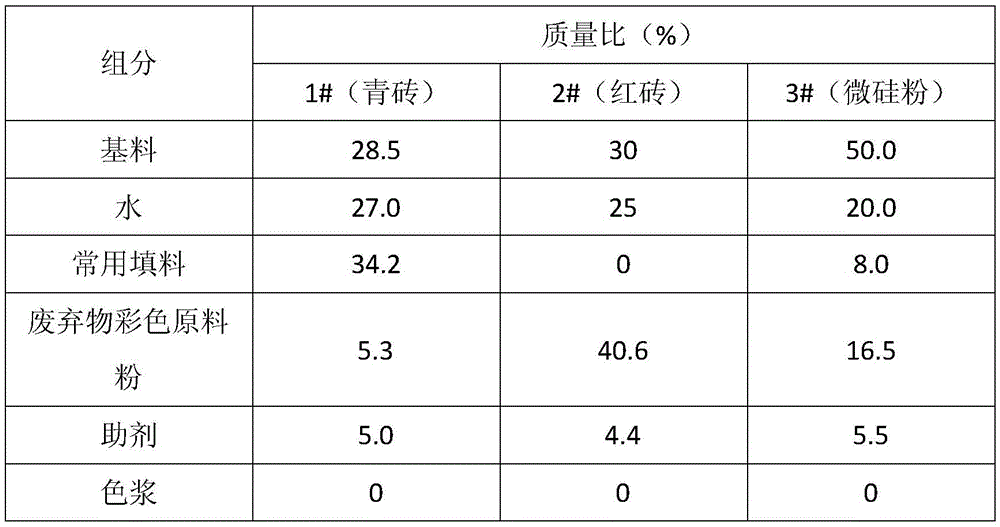

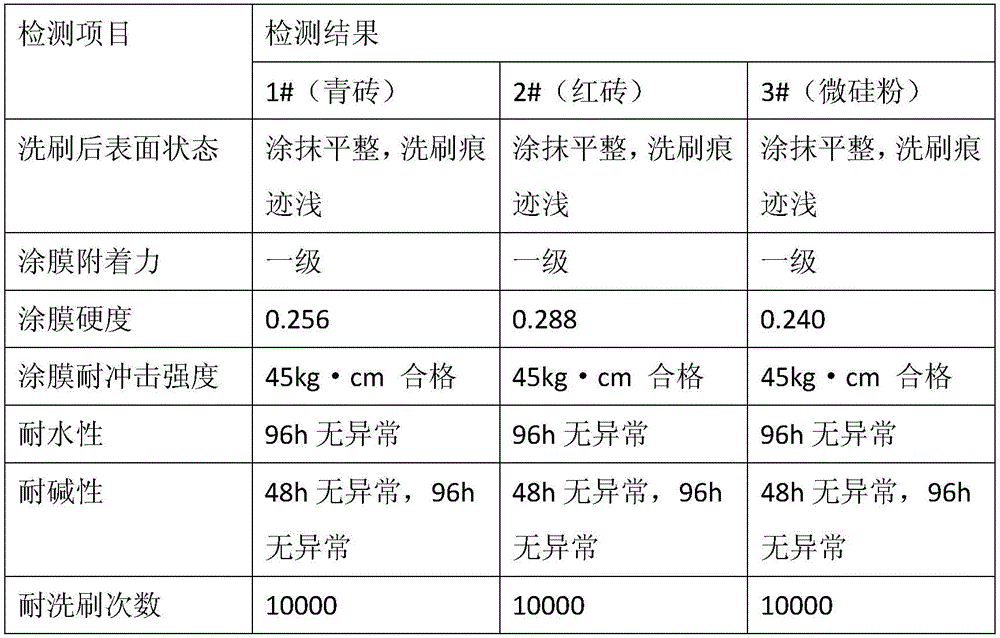

Examples

Embodiment 1

[0014] Embodiment 1: the preparation of red brick brick red raw material powder

[0015] 1. Waste sorting and recycling: firstly select recyclable waste, take construction solid waste wall material red brick as an example, filter out impurity wood, metal objects and mortar through manual sorting, and obtain recyclable waste Waste red brick fragments, which are cleaned;

[0016] 2. Cleaning and drying: Clean the recyclable waste red brick fragments, and dry them with an online dryer. After drying, the moisture content is below 2-3%. For the online dryer, please refer to CN201420333632. The online dryer provided in the utility model "A Kind of Online Dryer" of 5.

[0017] 3. Crushing and grinding: pass the dried red brick fragments through the jaw crusher, crush them into red brick particles with a particle size of 2-15mm, and then use a vertical mill for grinding to process into 30μm brick color powder abrasive.

[0018] 4. Surface modification: use titanate coupling agent t...

Embodiment 2

[0020] Embodiment 2: the preparation of yellow rust stone golden yellow raw material powder

[0021] 1. Waste sorting and recycling: firstly select recyclable waste, taking construction solid waste curtain wall stone yellow rust stone as an example, through manual sorting to screen out impurities such as silicone glue, metal objects and mortar, and obtain recyclable waste. Recycled waste yellow rust stone fragments.

[0022] 2. Cleaning and drying: Clean the recyclable waste yellow rust stone fragments and dry them on-line. After drying, the moisture content is below 2-3%.

[0023] 3. Crushing and grinding: pass the dried yellow rust stone fragments through the jaw crusher, crush them into yellow rust stone particles with a particle size of ≤20mm, and then use a ball mill for grinding to process into 40μm golden yellow powder abrasive.

[0024] 4. Surface modification: use titanate coupling agent to modify the surface of the golden yellow powder abrasive, and the dosage of t...

Embodiment 3

[0026] Embodiment 3: the preparation of fly ash gray raw material powder

[0027] 1. Waste crushing and grinding: first select the recyclable waste, and use the industrial solid waste fly ash (the fine ash collected from the flue gas after coal combustion is called fly ash, and fly ash is the The main solid waste discharged from coal power plants) as an example, because the fly ash is dry and has no other impurities, there is no need for sorting, recycling, cleaning, and drying steps, and the dry fly ash is directly ground by a vertical mill and processed into a 15μm gray powder abrasive.

[0028] 2. Surface modification: use silane coupling agent to modify the surface of the gray powder abrasive, and the amount of silane coupling agent is 1% of the mass of the gray powder abrasive.

[0029] 3. PH value adjustment: PH adjustment is carried out on the gray powder abrasive, the pH value is controlled between 8 and 9, and the gray raw material powder of fly ash is output.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com