Preparation method of intervertebral disc fibrous ring tissue engineering scaffold

A technology of tissue engineering scaffold and annulus fibrosus, which is applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of low simulation degree of fibrous annulus scaffold structure, lack of mechanical properties, and uncontrollable degradation rate, etc., to achieve beneficial Effects of Adhesive Growth, Good Biocompatibility, and High Porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

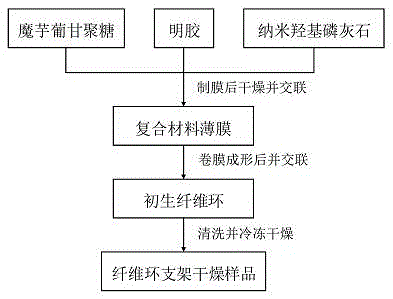

Method used

Image

Examples

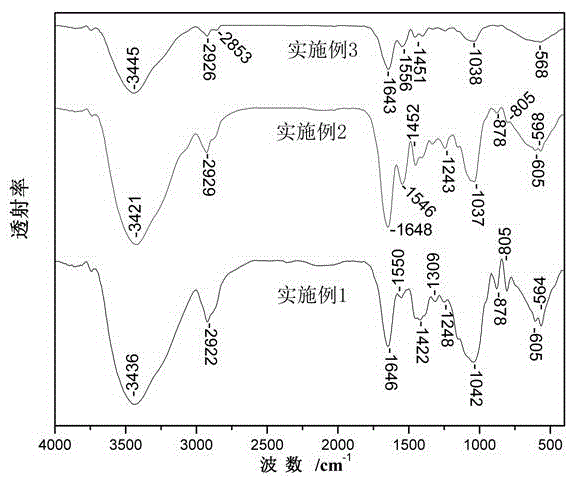

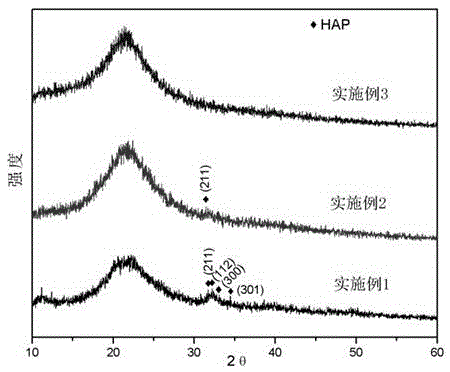

Embodiment 1

[0031] (1) Preparation of stock solution: add gelatin to distilled water and let it stand for 2 hours, then heat it in a water bath to 50°C, stir well until the gelatin is completely dissolved; then add nano-hydroxyapatite powder, and continue stirring until nano-hydroxyapatite powder is formed Form a uniform suspension state in the solution; add konjac glucomannan and stir until the konjac glucomannan is fully mixed with the suspension, the stirring speed is 1300r / min, and the time is 30min; After completion, take out and cool to room temperature to obtain stock solution; the concentration of konjac glucomannan in the stock solution is 30g / L, the concentration of gelatin is 25g / L, and the concentration of nano-hydroxyapatite is 15g / L.

[0032] (2) Film making: Pour the original solution on a specific template, the original solution flows under the action of gravity and spreads on the template to form a uniform thin layer, the thickness of the thin layer is 1mm, and then the fi...

Embodiment 2

[0040] (1) Preparation of stock solution: add gelatin to distilled water and let it stand for 5 hours, then heat it in a water bath to 60°C, stir well until the gelatin is completely dissolved; then add nano-hydroxyapatite powder, and continue stirring until nano-hydroxyapatite powder is formed Form a uniform suspension state in the solution; add konjac glucomannan and stir until the konjac glucomannan is fully mixed with the suspension, the stirring speed is 1400r / min, and the time is 40min; After completion, take out and cool to room temperature to obtain stock solution; the concentration of konjac glucomannan in the stock solution is 25g / L, the concentration of gelatin is 30g / L, and the concentration of nano-hydroxyapatite is 20g / L.

[0041] (2) Film making: Pour the original solution on a specific template, the original solution flows under the action of gravity and spreads on the template to form a uniform thin layer, the thickness of the thin layer is 3mm, and then the fi...

Embodiment 3

[0050] (1) Preparation of stock solution: Add gelatin to distilled water and let it stand for 12 hours, then heat it in a water bath to 70°C, stir well until the gelatin is completely dissolved; then add konjac glucomannan and stir until the konjac glucomannan is fully dissolved, the stirring speed is 1200r / min for 50min; then place it in a microwave oven with a power of 700W and heat it for 30s. After the heating is completed, take it out and cool it to room temperature to obtain the stock solution; the concentration of konjac glucomannan in the stock solution is 20g / L, and the concentration of gelatin is 35g / L.

[0051] (2) Membrane making: Pour the original solution on a specific template, and the original solution flows under the action of gravity and spreads on the template to form a uniform thin layer. Thin layer thickness is 2 mm. Subsequently, the film was dried in a drying oven at 55°C.

[0052] (3) Cross-linking of the membrane: The dried membrane was cross-linked b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com