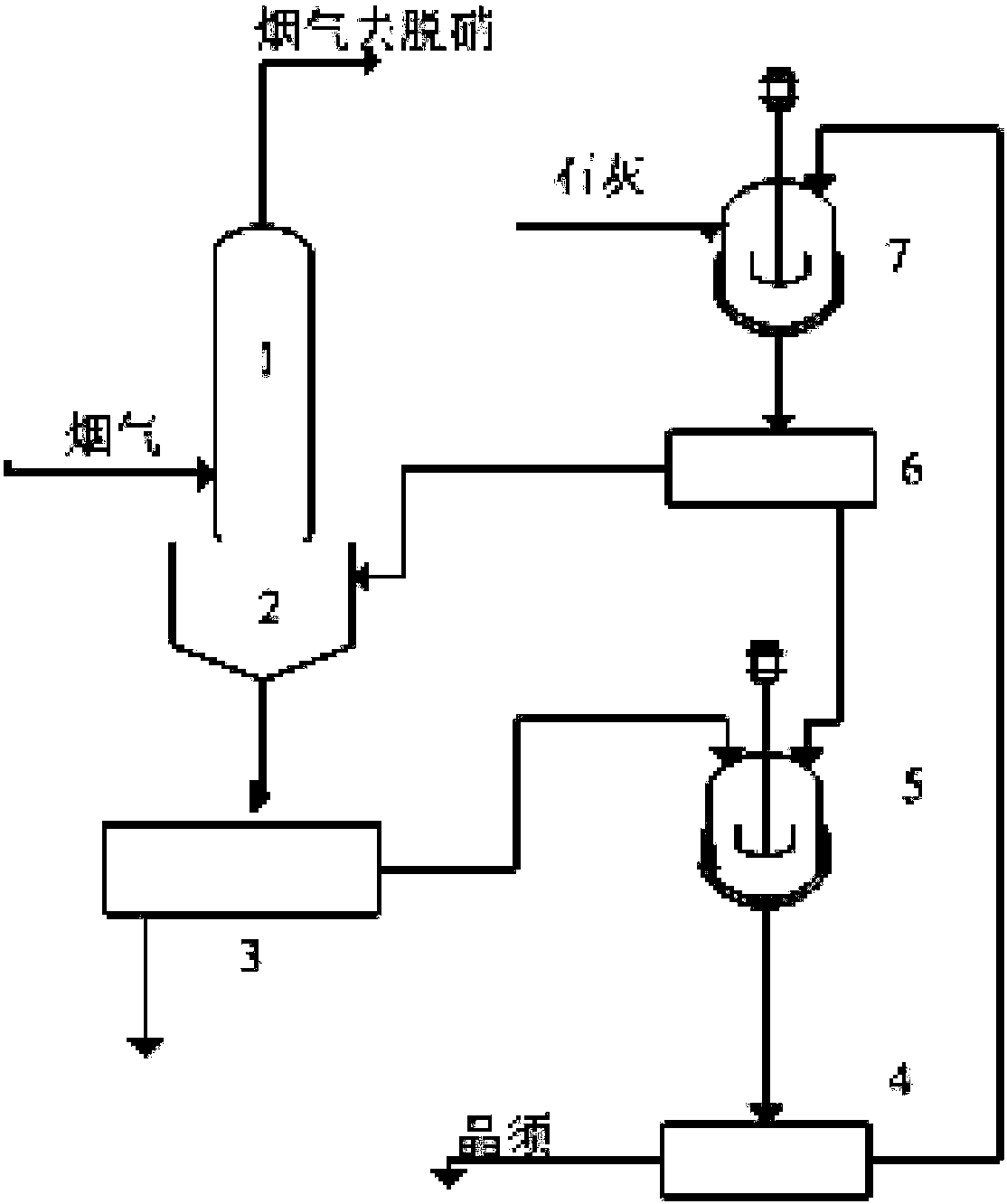

A method for deep removal of SO2 co-production gypsum whiskers in flue gas by calcium-magnesium fusion method

A technology of gypsum whiskers and flue gas, which is applied in the field of deep removal of SO2 in flue gas and co-production of gypsum whiskers by calcium-magnesium fusion method, can solve the problems affecting the quality, usage and sales price of gypsum whiskers, and achieve The effect of improving the quality of follow-up products, improving desulfurization efficiency, and expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Desulfurization tower packing height 2000mm, Mg(OH) 2 The slurry concentration is 2%, the operating temperature is 50°C, and the 2 1.2% simulated mixed gas 100L / min, liquid-gas ratio (L / G) = 1.5, measuring tower outlet SO 2 The concentration is 138PPM, and the desulfurization efficiency is 98.85%. Gradually add magnesium hydroxide to 10L slurry to keep Mg(OH) 2 The slurry concentration is about 1-2%, add Mg(OH) at 15h 2 1200g, measuring tower outlet SO 2 The concentration is 152PPM, and the desulfurization efficiency is 98.73%. Take the desulfurization mother liquor, pass through the air to oxidize and filter to get MgSO 4 Solution, measured concentration 1.62mol / L. MgSO 4 Solution 1L and 2.0mol / L calcium nitrate Ca(NO 3 ) 2 810mL of aqueous solution was heated to 98°C, added together into a 5000ml reactor, kept for 30 minutes, then filtered, washed, and dried at 105°C to obtain 216g of hemihydrate gypsum whiskers. The measured whisker whiteness is 96%, and th...

Embodiment 2

[0035] The flue gas flow into the desulfurization tower is 12000NM 3 / h,SO 2 1.03%, the temperature is 150°C, it is passed into the middle of the desulfurization tower, and it is in countercurrent contact with the circulating liquid sprayed from the upper part, the concentration of magnesium sulfate in the circulating liquid is 1.2mol / L, Mg(OH) 2 Slurry concentration 1-2%, operating temperature 50°C, liquid-gas ratio (L / G) = 1.5, measuring tower outlet SO 2 The concentration is 118PPM, and the desulfurization efficiency is 98.85%.

[0036] Take 10L of the desulfurization mother liquor after air oxidation, filter it, and dry the filter residue to obtain an off-white powder; the filtrate is measured for MgSO 4 The concentration is 1.22mol / L. Take calcium nitrate Ca(NO) adjusted to 2.0mol / L 3 ) 2 6.1L of aqueous solution was heated to 100°C, added together into a 20L reactor, kept warm and stirred for 30 minutes, filtered, washed, and dried at 105°C to obtain 1645g of hemihy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com