Method of two-step production of II type ammonium polyphosphate

A technology of ammonium polyphosphate and yellow phosphorus, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low polymerization degree of APP and human hazards, and achieve high safety, low hygroscopicity, and heat resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

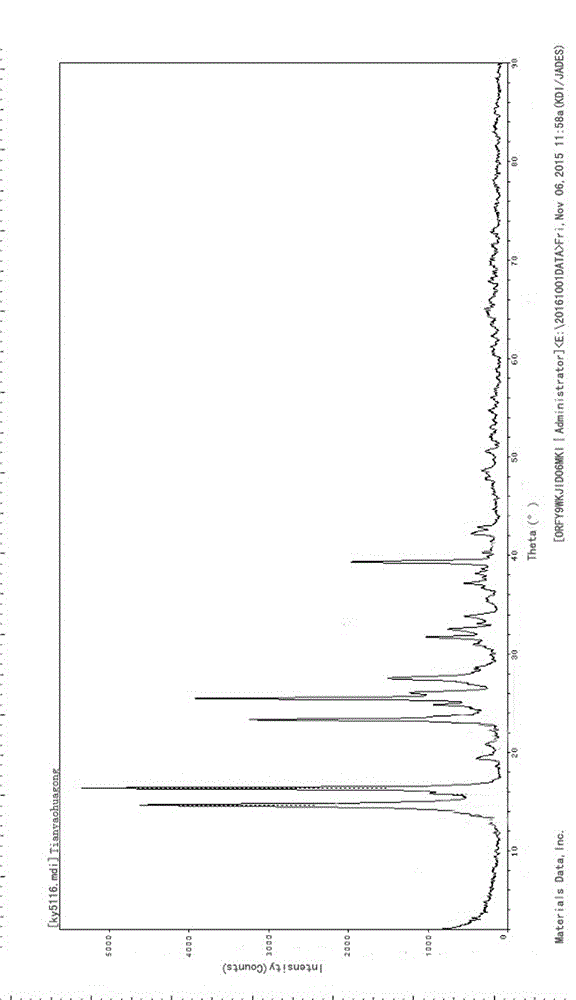

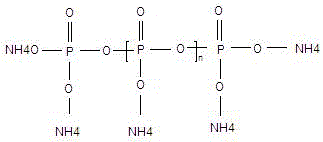

Image

Examples

Embodiment 1

[0032] After liquefied, 3kg of yellow phosphorus is sprayed into the combustion furnace through a phosphorus spray gun, and the air enters the phosphorus spray gun at the same time from the air compressor through the gas-water separator and the metering instrument. gaseous P 2 o 5 . Gaseous P 2 o 5 After cooling to 525°C with cooling water, it enters the reactor to react with ammonia gas and water vapor. The amount of ammonia gas and water vapor is 1.6kg and 0.8kg respectively, and the reaction temperature is 400°C. After 30 minutes of reaction, the white intermediate ammonium metaphosphate is obtained. Collect it after cooling, put it into the polymerization equipment, pass through ammonia to heat and polymerize. The polymerization temperature is 220°C, the gauge pressure is 0.7MPa, the rotation speed is 30r / min, and the reaction is for 2 hours. After cooling down the reaction product to 100°C, the ammonia flow is stopped, and the type II ammonium polyphosphate product is...

Embodiment 2

[0037] After liquefied, 0.08kg of yellow phosphorus is sprayed into the combustion furnace through the phosphorus spray gun, and the air enters the phosphorus spray gun through the air compressor through the gas-water separator and the meter at the same time. Combustion at ℃ to form gaseous P 2 o 5 . After cooling to 500°C with cooling water, it enters the reactor to react with ammonia gas and water vapor. The amount of ammonia gas and water vapor is 0.8kg and 0.8kg respectively, and the reaction temperature is 100°C. After 20 minutes of reaction, the white intermediate ammonium metaphosphate is obtained. Collect it after cooling, put it into the polymerization equipment, pass through ammonia to heat and polymerize. The polymerization temperature is 100°C, the gauge pressure is 0.05MPa, the rotation speed is 30r / min, and the reaction is 30min. After cooling down the reaction product to 100°C, the ammonia flow is stopped, and the type II ammonium polyphosphate product is obta...

Embodiment 3

[0041] After liquefied, 30kg of yellow phosphorus is sprayed into the combustion furnace through a phosphorus spray gun, and the air enters the phosphorus spray gun at the same time from the air compressor through the gas-water separator and metering instruments. gaseous P 2 o 5 . After cooling to 550°C with cooling water, it enters the Venturi reactor for reaction with ammonia gas and water vapor. The amount of ammonia gas and water vapor is 15kg and 3kg respectively, and the reaction temperature is 600°C. After 20 minutes of reaction, the white intermediate ammonium metaphosphate is obtained. Collect it after cooling, put it into a special polymerization equipment, and heat it with ammonia to polymerize. The polymerization temperature is 350°C, the gauge pressure is 1.5MPa, the rotation speed is 30r / min, and the reaction is carried out for 20 hours. After cooling the reaction product to 100°C, the ammonia flow is stopped, and the type II ammonium polyphosphate product is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com