Method for synthesizing alkyl pyrroles

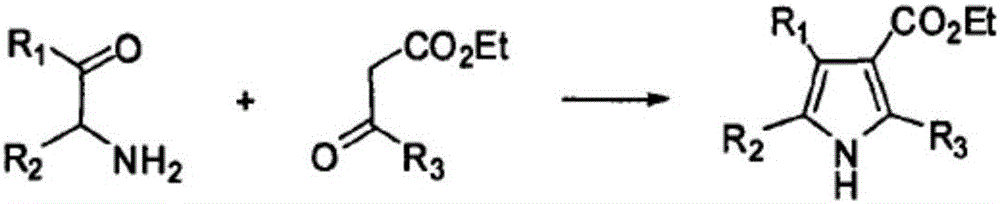

A technology for alkyl pyrroles and compounds, which is applied in the field of synthesizing alkyl pyrroles, can solve problems such as the synthesis of alkyl pyrroles that are not involved, and achieves the effects of high added value of products, simple and convenient operation process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

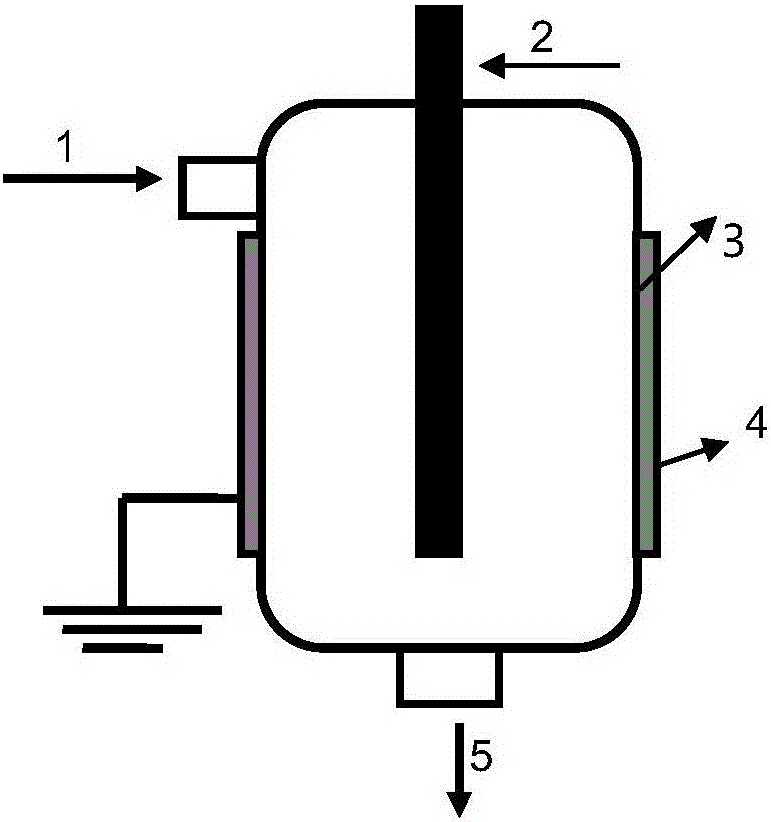

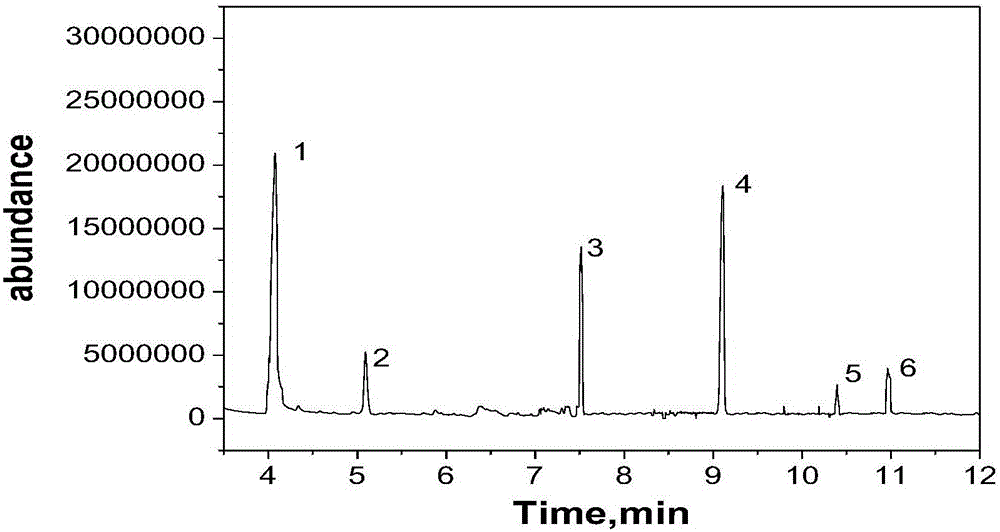

[0070] Catalyst MnSiO 2 (20-40 mesh), with a loading capacity of 5%, filled in the discharge area of the single-dielectric barrier discharge-wire barrel reactor, and the filling height is 50mm. At a pressure of 0.1MPa, ammonia gas and gaseous methanol are passed into the discharge area at a molar ratio of 4:1. After the gas flow is stable, the plasma power supply is turned on for dielectric barrier discharge. A cylindrical reactor made of quartz glass (also used as a barrier medium), in which the outer diameter of the outer tube is 11mm, the inner diameter is 9mm, the central electrode is stainless steel with a diameter of 2mm, the ground electrode is aluminum foil, and the distance between the two electrodes is 4mm. The effective discharge of the reactor The length is 50mm, the reactor structure, such as figure 1 shown.

[0071] The discharge parameters of the reactor are: discharge voltage 14.2kV, discharge power 36W, discharge frequency 12kHz, discharge zone temperature...

Embodiment 2

[0073] Repeat embodiment 1, fill the prepared CrSiO in the discharge area 2 The catalyst has a loading capacity of 5%, the particle size of the catalyst is 20-40 mesh, and the discharge zone temperature is 480-485°C. Then the reaction result is: the conversion rate of methanol is 53%. Product selectivity: formazan 9%, propionitrile 4%, N,N-dimethylaminoacetonitrile 7%, N,N-dimethylcyanamide 13%, aminoacetonitrile 7%, 2,3,5-tris Methyl pyrrole 3%, formamide 3%, methane 31%, CO 11%.

Embodiment 3

[0075] Repeat embodiment 1, fill the prepared ZnSiO in the discharge area 2 The catalyst has a loading capacity of 5%, the particle size of the catalyst is 20-40 mesh, and the discharge zone temperature is 486-487°C. Then the reaction result is: methanol conversion rate 67%, product selectivity: formazan 11%, propionitrile 3%, N,N-dimethylcyanamide 15%, aminoacetonitrile 7%, 2,3,5-trimethylcyanamide 1% pyrrole, 2%, 2,3,4,5-tetramethylpyrrole, 8% formamide, 23% methane, 28% CO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com