All-lyophobic bionic anti-fouling self-cleaning coating and preparation method thereof

A self-cleaning coating, bionic antifouling technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of difficult large area preparation, long cycle, harsh conditions, etc. The effect of good performance, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

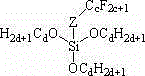

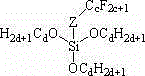

[0033] Under the protection of nitrogen, mix the silane coupling agent, short fluorocarbon chain substituted silane coupling agent, silica sol and solvent at 30°C, add water dropwise while reacting, and hydrolyze and condense for 2 hours to obtain a hydrophobic coating; the above The components are in mass percentage, 3% silane coupling agent, 10% short fluorocarbon chain substituted silane coupling agent, 40% silica sol, 10% solvent and 37% water.

[0034] The hydrophobic coating prepared above was spin-coated on the surface of a glass slide, and heat-treated at 120° C. for 2 hours to obtain the first coating, which was a hydrophobic coating, and then soaked in the perfluorinated lubricant. By removing excess lubricating fluid, a fully lyophobic biomimetic antifouling self-cleaning coating is obtained.

[0035] In this example, the silane coupling agent is methyltriethoxysilane; the silica sol component is a silica propanol solution with a pH=2, a solid content of 50%, and a ...

Embodiment 2

[0037] Under the protection of nitrogen, mix the silane coupling agent, short fluorocarbon chain substituted silane coupling agent, silica sol and solvent at 40°C, add water dropwise while reacting, and hydrolyze and condense for 1 hour to obtain a hydrophobic coating; the above Components by mass percentage, silane coupling agent 6%, short fluorocarbon chain substituted silane coupling agent 6%, silica sol 25%, solvent 30% and water 33%.

[0038] The hydrophobic coating prepared above was spin-coated on the surface of a glass slide, and heat-treated at 120 ° C for 3 hours to obtain the first coating, which was a hydrophobic coating, and then soaked in the perfluorinated lubricant, By removing excess lubricating fluid, a fully lyophobic biomimetic antifouling self-cleaning coating is obtained.

[0039] In this example, the silane coupling agent is dimethyldimethoxysilane; the silica sol component is a silica isopropanol solution with a pH=3, a solid content of 30%, and a parti...

Embodiment 3

[0041] Under the protection of nitrogen, mix the silane coupling agent, short fluorocarbon chain substituted silane coupling agent, silica sol and solvent at 10°C, add water dropwise while reacting, and hydrolyze and condense for 5 hours to obtain a hydrophobic coating; the above Components by mass percentage, silane coupling agent 10%, short fluorocarbon chain substituted silane coupling agent 3%, silica sol 12%, solvent 21% and water 56%.

[0042] Spin-coat the hydrophobic coating prepared above onto the surface of the silicon wafer, and heat-treat it at 80°C for 5 hours to obtain the first coating, which is a hydrophobic coating. By removing excess lubricating fluid, a fully lyophobic bionic anti-fouling self-cleaning coating is obtained.

[0043]In this embodiment, the silane coupling agent is phenyltriethoxysilane; the silica sol component is a silica isopropanol solution with a pH=6, a solid content of 5%, and a particle size of 70nm; a short fluorocarbon chain The subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com