Zinc-nickel alloy coating and zinc coating nano modified sealant, and preparation and application methods thereof

A zinc-nickel alloy, nano-modified technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of low lubricity and wear resistance of the sealing layer, increase the hardness and self-lubrication of the film layer, etc. , to increase the hardness and self-lubrication, solve the low lubricating performance and wear resistance, and eliminate unstable factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] For a better understanding of the present invention, the present invention will be further specifically described through the following examples, but it should not be understood as a limitation of the present invention, and some non-essential improvements and adjustments made by those skilled in the art according to the content of the above invention are also accepted. deemed to fall within the protection scope of the present invention.

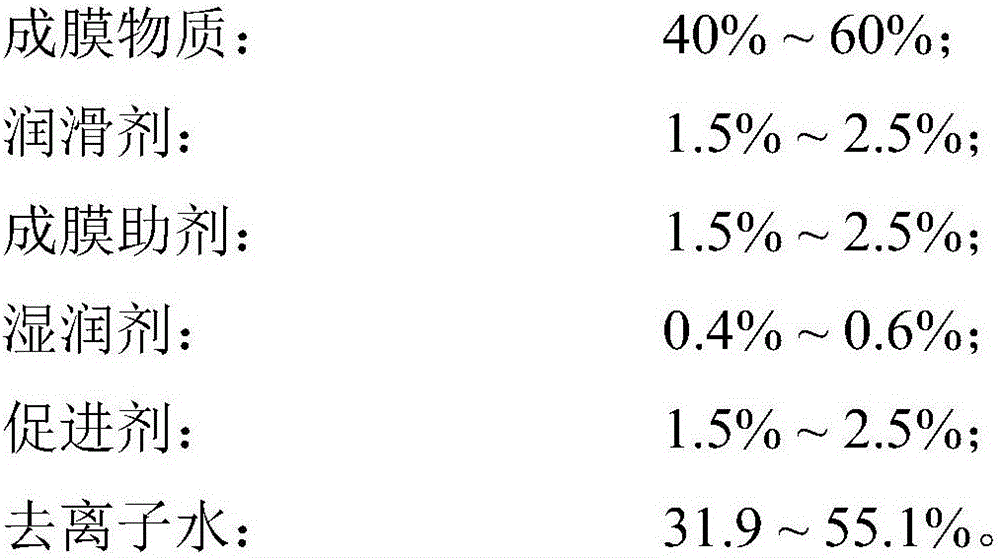

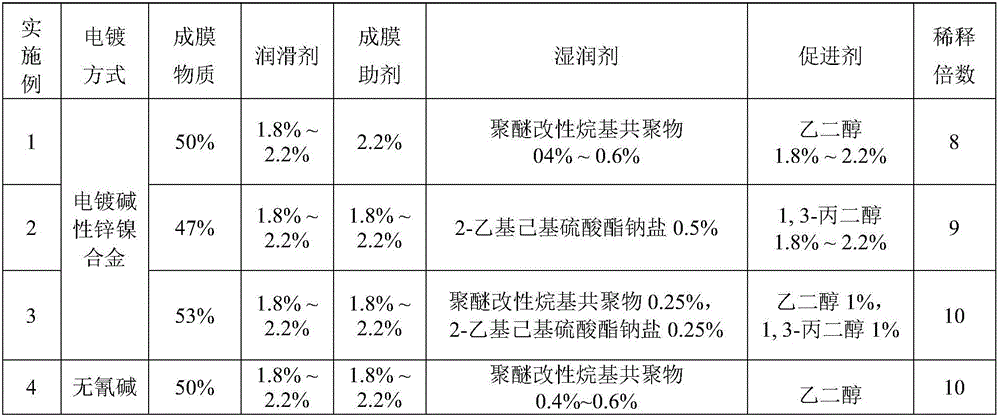

[0039] According to the proportioning of each of the following examples, the sealing agent is prepared:

[0040] Table 1 The composition and proportioning of the nano-modified sealing agent of the present invention

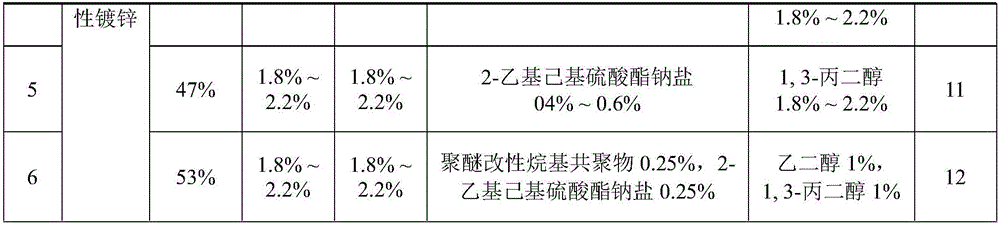

[0041]

[0042]

[0043] Unless otherwise specified in the table, the film-forming substances include water-soluble polyurethane and water-soluble silane polymers, in which water-soluble polyurethane accounts for 75% to 85% of the mass fraction of film-forming substances, and water-soluble silane polymers account for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com