Preparation method of layered composite proton exchange membrane for fuel cell

A proton exchange membrane, layered composite technology, used in fuel cells, circuits, electrical components, etc., can solve the problems of unsatisfactory mechanical properties of composite membranes, low swelling effect of membrane materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

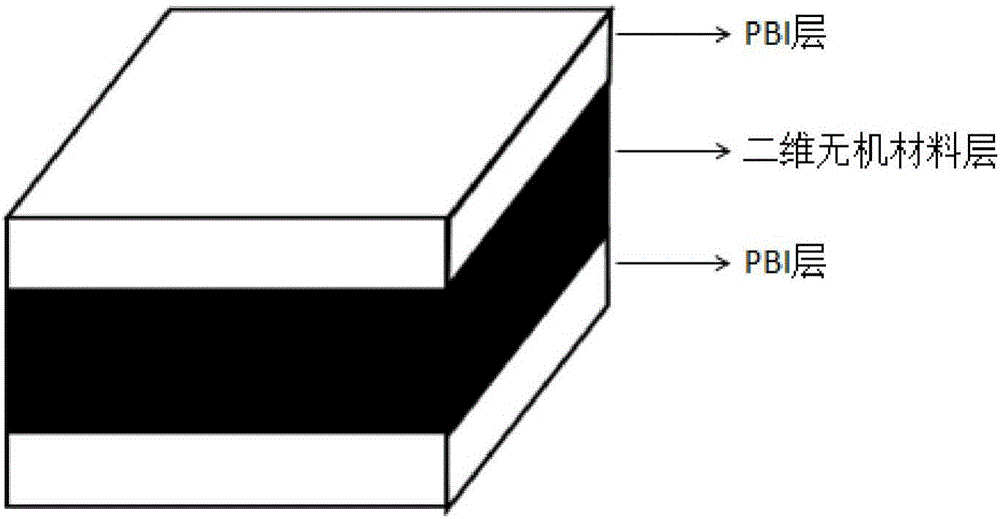

[0030] The three-layer composite proton exchange membrane used for fuel cells in this embodiment has a three-layer layered structure, which is composed of polybenzimidazole (PBI), graphene oxide and polybenzimidazole (PBI) respectively, and its preparation method is as follows :

[0031] 1. Weigh 0.2g polybenzimidazole powder (PBI) and add it into 5ml N-N dimethylacetamide solvent, stir and dissolve at 130°C for 8h, then centrifuge at 11000rpm, filter to obtain PBI solution .

[0032] 2. Take 3g of graphite powder, 18g of potassium permanganate, mix with 360ml of sulfuric acid solution with a mass concentration of 98% and 40ml of a phosphoric acid solution with a mass concentration of 85%, stir and react at 50°C for 12h, and cool to room temperature after the reaction. Pour the reaction solution into 400ml containing 10mlH 2 o 2 in ice water, washed three times with hydrochloric acid solution (37% mass concentration) and deionized water successively, and dried to obtain gra...

Embodiment 2

[0045] The five-layer composite proton exchange membrane used for fuel cells in the present embodiment has a five-layer layered structure, composed of polybenzimidazole (PBI), graphene oxide, PBI, graphene oxide and PBI, and its preparation method is as follows:

[0046] 1. Weigh 0.4g of polybenzimidazole powder (PBI) and add it to 5ml of N-N dimethylacetamide solvent, stir and dissolve at 130°C for 8h, then centrifuge at 11000 rpm, and obtain PBI solution after filtration .

[0047] 2, get 3g graphite powder, 18g potassium permanganate and the mixed solution of sulfuric acid solution of 360ml mass concentration 98% and 40ml phosphoric acid solution (85wt%) mix, stir reaction 12h at 50 ℃, cool to room temperature after reaction finishes, The reaction solution was poured into 400ml containing 10mlH 2 o 2 in ice water, washed three times with hydrochloric acid solution (37wt%) and deionized water successively, and dried to obtain graphene oxide (GO).

[0048] 3. The PBI solutio...

Embodiment 3

[0056] The three-layer composite proton exchange membrane used for fuel cells in this embodiment has a three-layer layered structure, which is composed of polybenzimidazole (PBI), MXene, and PBI respectively. The preparation method is as follows:

[0057] 1. Weigh 0.2g polybenzimidazole powder (PBI) and add it into 5ml N-N dimethylacetamide solvent, stir and dissolve at 130°C for 8h, then centrifuge at 11000rpm, filter to obtain PBI solution .

[0058] 2. Take 3gMAX (Ti n+1 AlC n (n=1, 2, 3)) After 2M concentration of ammonium bifluoride (NH 4 HF) After 6 hours of etching, Ti with quaternary ammonium groups on the surface was obtained n+1 C n T x -NH 4 , and washed repeatedly with deionized water. Soak it in 1M phosphoric acid solution, take it out, wash it with deionized water, and dry it to get MXene.

[0059] 3. Mix 0.1g MXene and PBI solution containing 0.0752g PBI evenly to obtain PBI-MXene mixture;

[0060] 4. Slowly pour the PBI solution with a mass fraction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com