Diseased animal pyrolysis and charring treatment system

A technology of pyrolytic carbonization and treatment system, which is applied in the field of pyrolytic carbonization treatment system for sick animals, can solve problems such as cost increase, waste of resources, complex equipment, etc., and achieve the effects of improving utilization efficiency, avoiding leakage corrosion, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

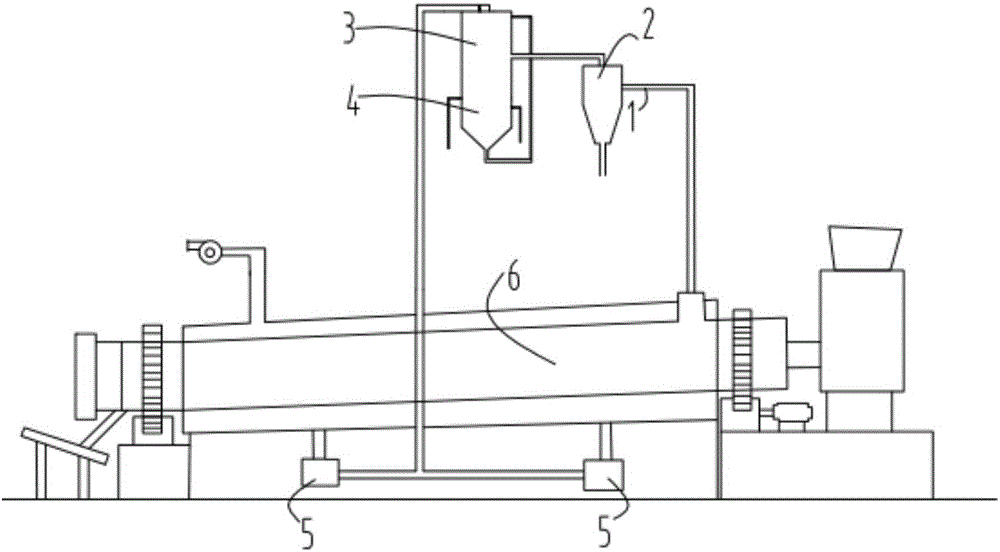

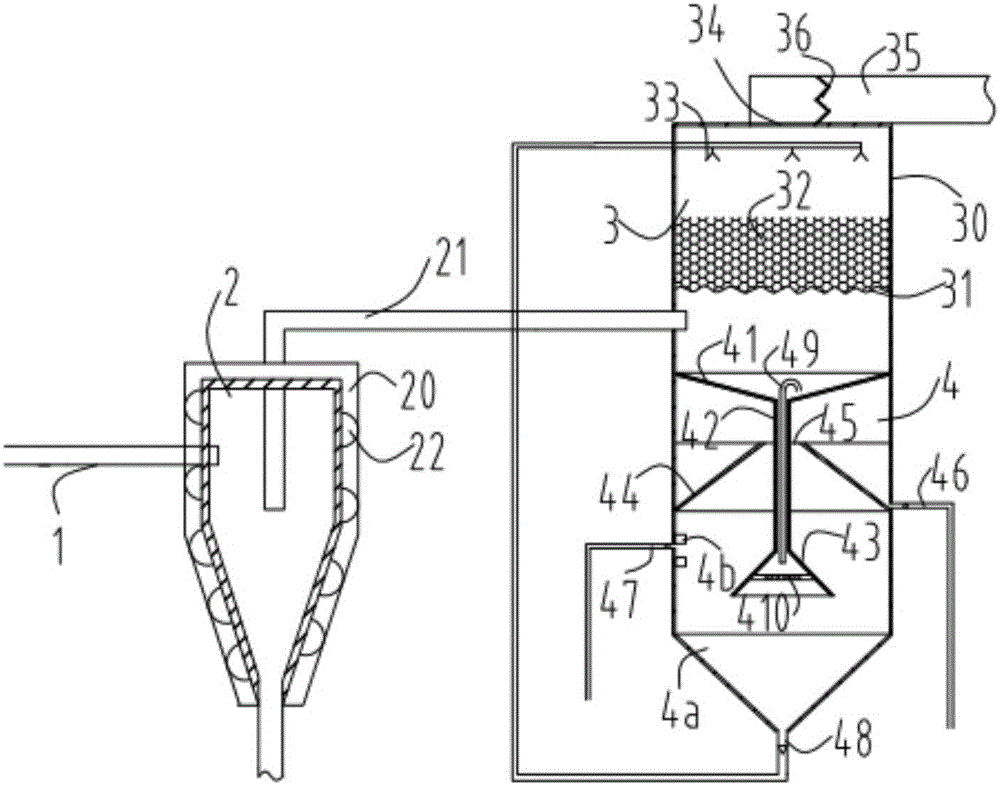

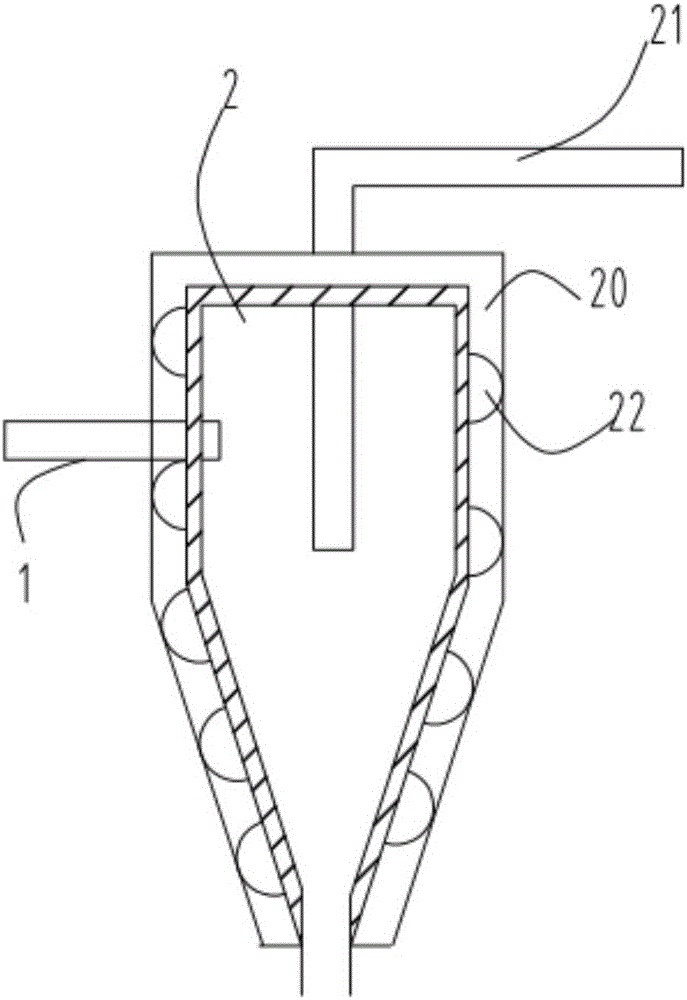

[0035] figure 1 It is a schematic diagram of the overall structure of a kind of sick animal pyrolysis carbonization treatment system of the present invention, figure 2 It is a schematic diagram of the structure of the cyclone dust collector, the spray treatment tower and the oil-water separator, image 3 Schematic diagram of the overall structure of the cyclone dust collector, Figure 4 Schematic diagram of the overall structure of the burner, Figure 5 It is a schematic diagram of the structure of the spray treatment tower and the oil-water separator, Figure 6 It is a schematic view of the burner from the right side, Figure 7 Schematic diagram of the burner venturi tube. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, what is provided in the present embodiment is a kind of pyrolysis carbonization treatment system for sick animals, comprising cyclone dust collector 2, spray treatment tower 3, oil-water separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com