Thermal desorption method and device for activated carbon

A technology of activated carbon and thermal analysis, which is applied in separation methods, chemical instruments and methods, and other chemical processes, and can solve problems such as loss of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

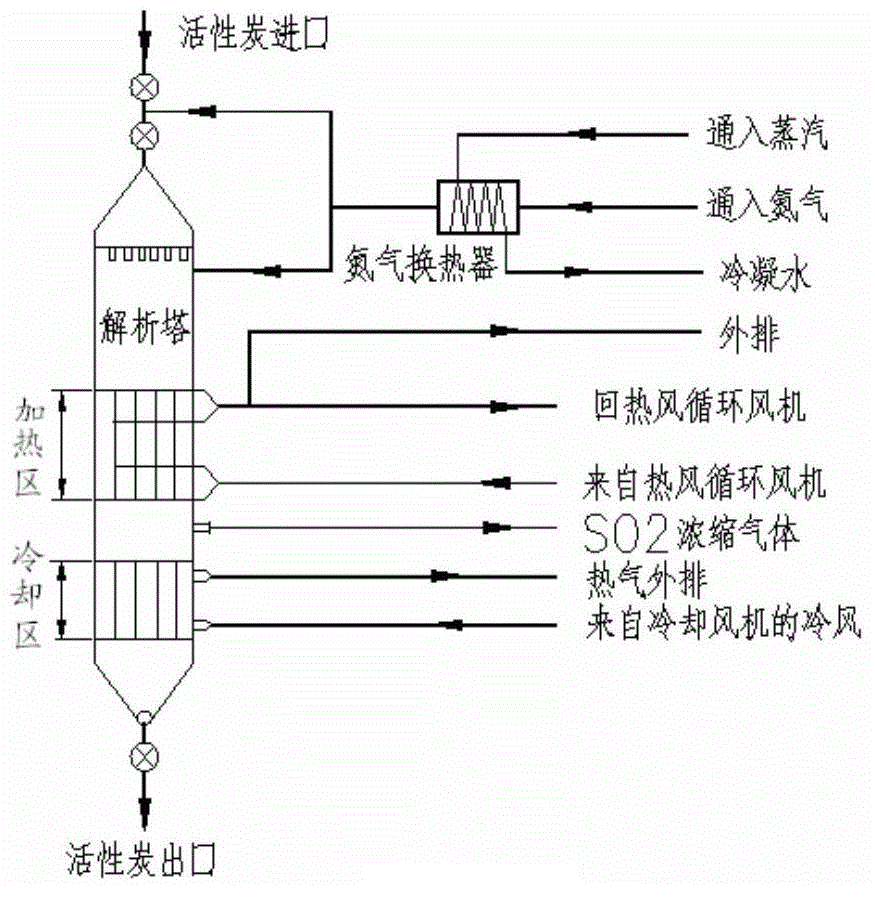

[0183] In addition, according to the first embodiment of the present invention, there is also provided a thermal analysis method comprising activated carbon utilizing waste heat utilizing the above-mentioned device, the method comprising the following steps:

[0184] 1) In the activated carbon adsorption tower of the desulfurization and denitrification device, the activated carbon that has adsorbed pollutants including sulfur oxides, nitrogen oxides and dioxins from the sintering flue gas is transferred from the bottom of the adsorption tower to the activated carbon analysis tower. In the heating zone, wherein the desulfurization and denitrification devices include an activated carbon adsorption tower and a desorption tower, and wherein the desorption tower (or regeneration tower) has an upper heating zone and a lower cooling zone;

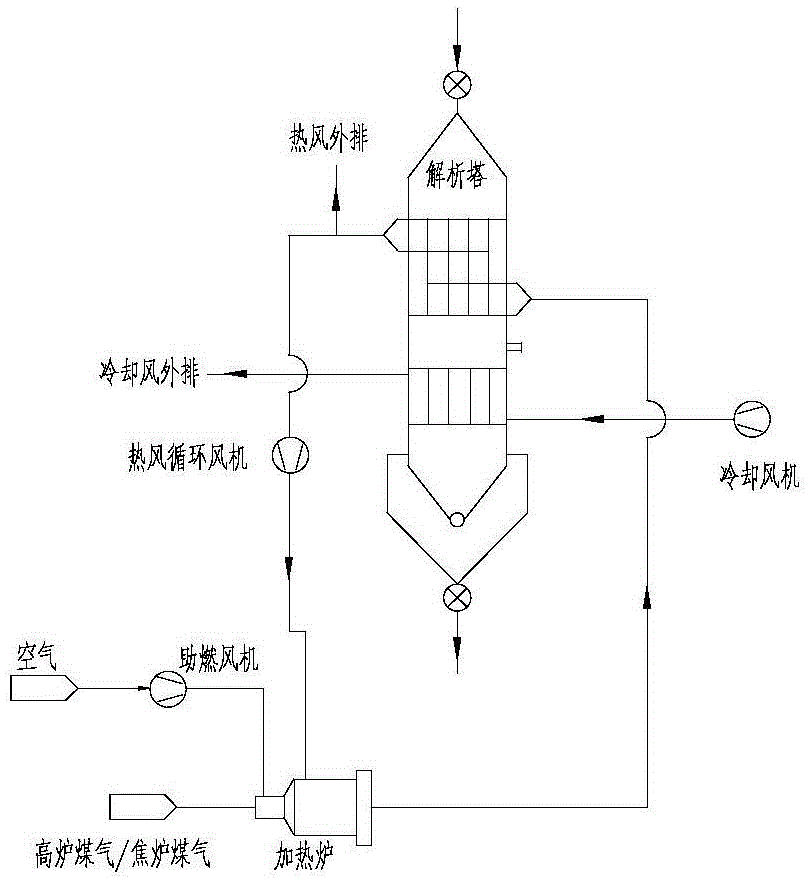

[0185] 2) Blast furnace gas or coke oven gas (optionally after being preheated by flowing through a gas heat exchanger) is delivered to the heatin...

Embodiment 1

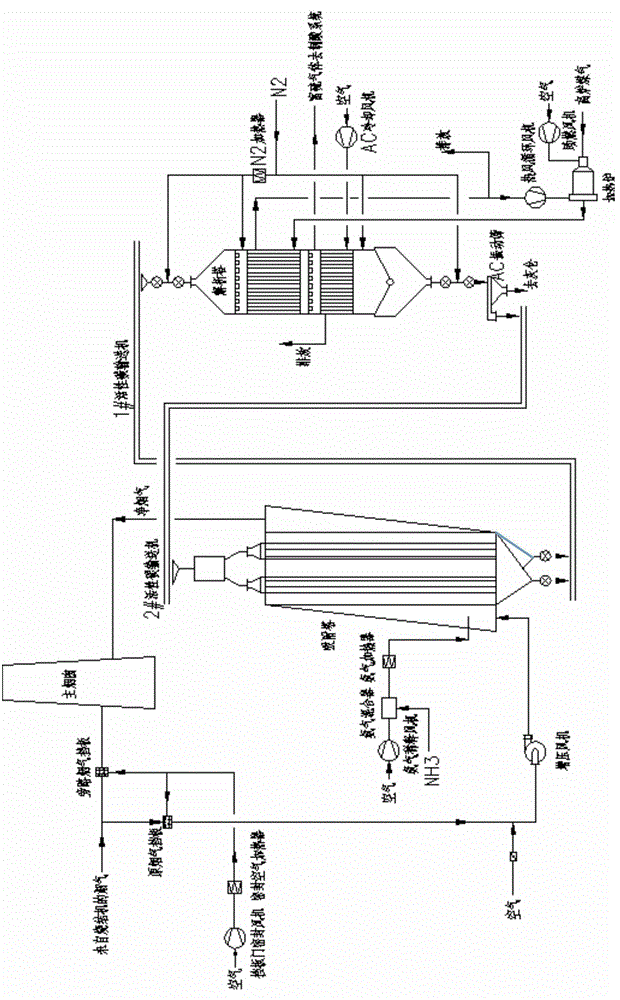

[0210] Such as Figure 5 Shown in, desulfurization, denitrification device comprises activated carbon adsorption tower (20) (tower height 30 meters, cross-sectional area 120m 2 ) and analytical tower (as shown in Figure 2, the tower is 20 meters high and the cross-sectional area is 15m 2 ). The tower body of activated carbon adsorption tower (see Figure 8 ) has a multi-layered chamber structure parallel to each other in the vertical direction, that is, the left air outlet chamber B ← denitration chamber c ← desulfurization, denitration chamber b ← desulfurization chamber a ← intake chamber A → desulfurization chamber a → desulfurization, denitration Chamber b → denitrification chamber c → right outlet chamber B, in which the flue gas flows from the inner air inlet chamber A substantially horizontally outward along the left and right directions (to the B outlet chamber). For drawing convenience, Figure 5 The reaction tower (or adsorption tower) in is described as a single...

Embodiment 2

[0220] Repeat embodiment 1, just, wherein: all of the hot blast G1 ' that is exhausted from the hot blast outlet of the heating zone of desorption tower is divided into two hot blast airflows, i.e. the first hot blast airflow and the second hot blast airflow, both according to 15: The volume ratio or flow ratio of 85, wherein the first hot air flow (about 300°C) (accounting for 15vol% of the total external hot air volume or flow) is sent to the gas heat exchanger (11) upstream of the heating furnace (6) It is used to preheat the coke oven gas, and the second hot air flow (about 300°C) is sent to the temperature regulation zone (or mixing, buffer zone) at the end of the heating furnace (6) and discharged from the combustion chamber and enters the temperature regulation zone. The high-temperature hot air (G0) (about 1900°C) in the zone is mixed to adjust the temperature to 415-420°C, thus forming the hot air (G1) of the mixture, and the hot air (G1) is transported to the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com