Composite photo-catalyst with molybdenum disulfide (MoS2) nanosheet/cadmium sulfide (CdS) nanowire core-shell structure

A core-shell structure and nanowire technology, which is applied in the field of MoS2 nanosheet/CdS nanowire core-shell structure composite photocatalyst and its preparation, can solve the problem of not having special properties of core-shell structure, difficult CdS photostability, and complex preparation methods etc. to achieve good photostability, improve photocatalytic activity, and improve photostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of CdS Nanowire Precursor

[0030] Dissolve the copper reagent (sodium diethyldithiocarbamate) in an appropriate amount of deionized water at room temperature, then add chromium chloride at a molar ratio of copper reagent to chromium chloride of 2:1, and stir magnetically for 2 hours to obtain CdS precursor Cd(S 2 CNEt 2 ) 2 , the obtained product was washed three times with deionized water and ethanol respectively, the precipitate was collected by centrifugation, and dried in vacuum.

Embodiment 2

[0031] Example 2 Preparation of CdS nanowires

[0032] With the Cd(S) that makes in embodiment 1 2 CNEt 2 ) 2Add 0.9g~1.3g into the polytetrafluoroethylene reactor, add ethylenediamine to 80% of the volume of the reactor, magnetically stir until it is completely dissolved, react it at 180°C for 24 hours, and cool the obtained product to room temperature naturally, respectively Wash with deionized water and ethanol several times, collect the precipitate by centrifugation, and dry in vacuum to obtain CdS nanowires.

Embodiment 3

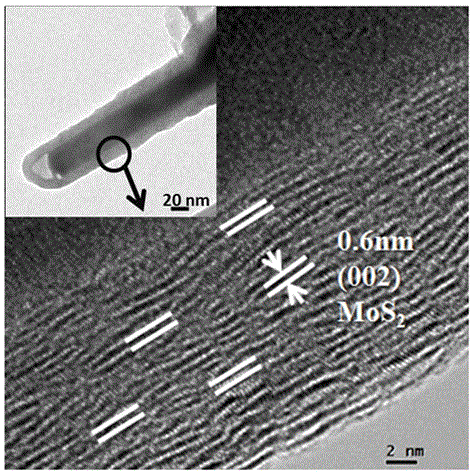

[0033] Example 3 Preparation of MoS 2 / CdS composite material

[0034] Ultrasonic disperse 50 mg of the CdS nanowires prepared in Example 2 in hydrochloric acid at pH=1, and magnetically stir for 24 hours to obtain acid-treated CdS nanowires, and ultrasonically disperse the acid-treated CdS nanowires in 40 mL of water , then add 25mg sodium molybdate dihydrate and 50mg thioacetamide successively, stir evenly, transfer to a polytetrafluoroethylene reactor, heat up to 200°C, and keep the temperature for 24 hours; the obtained product is naturally cooled to room temperature, and used respectively Wash with ionized water and ethanol several times, collect the precipitate by centrifugation, and dry in vacuum to obtain MoS 2 Nanosheet / CdS nanowire core-shell structure composite photocatalyst.

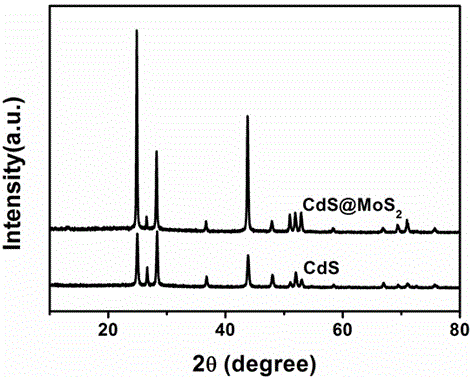

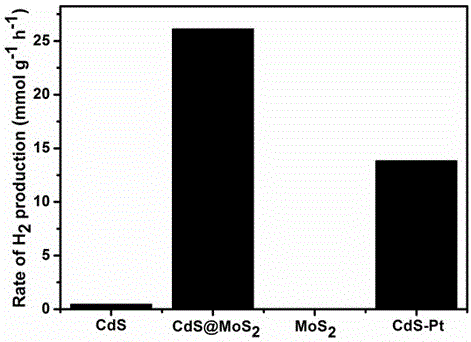

[0035] figure 1 For the pure CdS nanowires obtained in Example 2 and the two-dimensional MoS obtained in Example 3 2 X-ray diffraction pattern of nanosheet / CdS nanowire core-shell struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com