Graphene oxide-modified silicone rubber composite and preparation method thereof

A graphene modification and composite material technology, applied in the field of materials science, can solve problems such as reliability, UV resistance, thermal aging performance that cannot meet packaging requirements, and achieve significant technological progress, improved dispersibility, and no decrease in light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

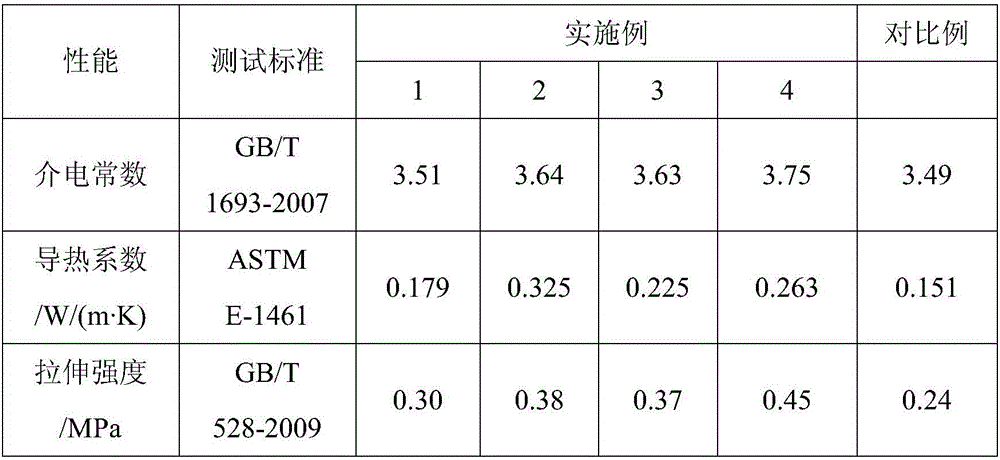

Embodiment 1

[0030] Add 0.2g of graphene oxide and 200g of absolute ethanol into a 500mL four-necked flask, and disperse into a uniform solution under ultrasonic wave of 500W for 30min. Put the flask in an oil bath, add 2 g of silane coupling agent KH550 dissolved in 5 g of absolute ethanol under mechanical stirring, and heat up at 80° C. for 24 h under reflux. Cool down after the reaction, centrifuge the mixture at a centrifugal speed of 10,000r / min for 6min, wash the precipitate repeatedly with absolute ethanol, dry the precipitate at 60°C for 24h in vacuum, and grind to obtain the silane coupling agent-modified Graphene oxide.

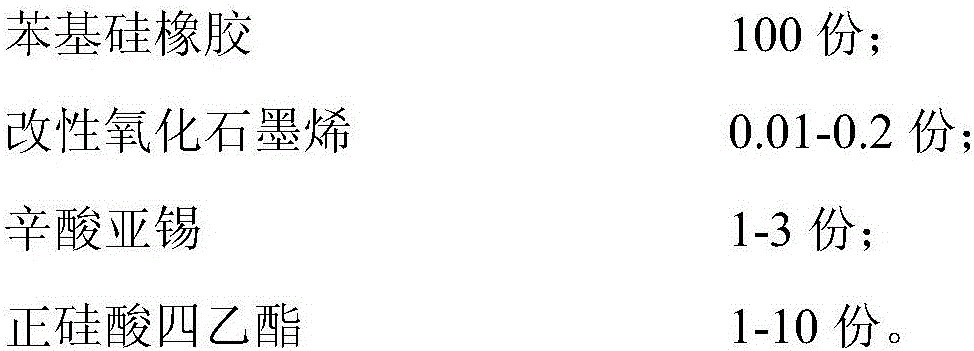

[0031] Weigh 100g of phenyl silicone rubber, add 0.01% modified graphene oxide to 5g of acetone for ultrasonic dispersion for 30min, add it into the silicone rubber and ultrasonically disperse for 30min, then raise the temperature to 60°C to remove the solvent. After the solvent is evaporated to dryness, add 1g of stannous octoate and 1g of tetraethyl orthosili...

Embodiment 2

[0033] Add 0.2g of graphene oxide and 200g of absolute ethanol into a 500mL four-necked flask, and disperse into a uniform solution under ultrasonic wave of 500W for 30min. Put the flask in an oil bath, add 2 g of silane coupling agent KH550 dissolved in 5 g of absolute ethanol under mechanical stirring, and heat up at 80° C. for 24 h under reflux. Cool down after the reaction, centrifuge the mixture at a centrifugal speed of 10,000r / min for 6min, wash the precipitate repeatedly with absolute ethanol, dry the precipitate at 60°C for 24h in vacuum, and grind to obtain the silane coupling agent-modified Graphene oxide.

[0034] Weigh 100g of phenyl silicone rubber, add 0.1% modified graphene oxide to 10g of acetone for ultrasonic dispersion for 30min, add it into the silicone rubber and ultrasonically disperse for 30min, then raise the temperature to 60°C to remove the solvent. After the solvent is evaporated to dryness, add 2g of stannous octoate and 5g of tetraethyl orthosili...

Embodiment 3

[0036] Add 0.2g of graphene oxide and 200g of N,N-dimethylformamide (DMF) into a 500mL four-neck flask for ultrasonic dispersion for 30min, place in an oil bath, heat up to 80°C with mechanical stirring, fill with nitrogen, add 5g of DMF to dissolve 2g of diphenylmethane diisocyanate (MDI) was added dropwise to 5 drops of dibutyltin dilaurate, and reacted for 24h under a nitrogen atmosphere. After the reaction, the reaction solution was centrifuged at a speed of 10000r / min, and the reaction solution was repeatedly washed with DMF and then acetone until the residual MDI was completely washed away, and the solid obtained by centrifugation was dried at 50°C for 24 hours in vacuum, and it was ready after grinding. Isocyanate-modified graphene oxide was obtained.

[0037] Weigh 100g of phenyl silicone rubber, add 0.1% modified graphene oxide into 10g of acetone for ultrasonic dispersion for 30min, add it into the silicone rubber and ultrasonically disperse for 30min, and raise the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com