Water-borne epoxy resin emulsion, anticorrosive paint and preparing method thereof

A water-based epoxy resin and anti-corrosion coating technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of coagulation, uneven curing, poor storage stability, etc., and achieve simple production process, excellent workability, and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The preparation method of the above-mentioned emulsion can be achieved by reacting epoxy resin and methoxy poly(oxyethylene / oxypropylene)-2-propylamine in the solution, and the temperature is preferably in the range of 50-70°C, so as to realize that it cannot be directly dissolved in water. The epoxy resin is "hydrophilic" bridged with methoxypoly(oxyethylene / oxypropylene)-2-propylamine, using -COOH, -OH at one end of the epoxy resin and methoxypoly(oxyethylene / oxypropylene) )-2-propylamine reaction, one end generates a salt, and the other end of methoxy poly(oxyethylene / oxypropylene)-2-propylamine contains a large number of hydrophilic groups, so that the original water-insoluble epoxy resin can be very good soluble in water.

[0083] After the reaction is completed, it is mixed with defoamer, neutralizer, and deionized water to prepare a modified epoxy resin emulsion, preferably using a phase inversion emulsification method. First, a W / O type emulsion can be obtained...

Embodiment 1~7

[0124] Examples 1-7 This example is used to illustrate the preparation of different modified epoxy resin emulsions

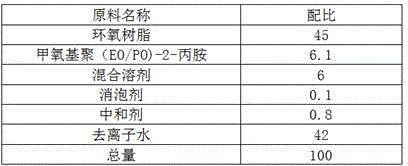

[0125] The raw materials are as follows:

[0126] Epoxy 128 (E51), Nan Ya Epoxy Resin

[0127] Methoxy poly(EO / PO)-2-propylamine adopts the following different A components and B components and their combinations:

[0128] A component:

[0129] ; Among them, x=6, y=35;

[0130] B component:

[0131] ; Among them, x=6, y=35;

[0132] Table 1: Weight ratio of component A to component B of methoxy poly(EO / PO)-2-propylamine in each example

[0133]

[0134] Defoamer (2550 BASF)

[0135] Neutralizer (DMAE Haimingsi Chemical)

[0136] Mixed solvent (ethylene glycol monobutyl ether: ethylene glycol: acetone = 40: 40: 20)

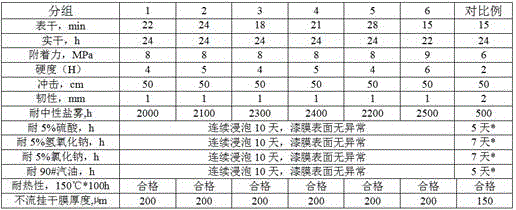

[0137] Table 2: Example 1-Example 7 Waterborne Epoxy Resin Emulsion Formula Ratio (weight percent)

[0138]

[0139] Preparation:

[0140] Step 1, mix the epoxy resin and solvent, heat up to 60°C, and stir well;

[0141] Step 2: Ad...

Embodiment 8

[0143] Embodiment 8 waterborne epoxy zinc-rich primer formula

[0144] The first component: water-based epoxy resin emulsion (the emulsion prepared in the above-mentioned Examples 1-7)

[0145] The raw materials for the second component are as follows:

[0146] High-purity zinc powder (500 mesh high-purity zinc powder Jiangsu Kecheng Zinc Industry)

[0147] Water-based zinc phosphate (PZ04 Huanqi Chemical)

[0148] Dispersant (755W Tego)

[0149] Second defoamer (0670 US OMG)

[0150] Wetting agent (2817 American Hexion)

[0151] Corrosion inhibitor (142DA Shanghai Yingshui)

[0152] Water-based polyamide wax paste (AQH-800 Lihuaxin)

[0153] Coalescing agent (Ethylene glycol monobutyl ether American Dow)

[0154] Waterborne epoxy curing agent (EK8538-Y-68 Hexion, USA)

[0155] Anti-flash rust agent (AH10 Shanghai Yingshui)

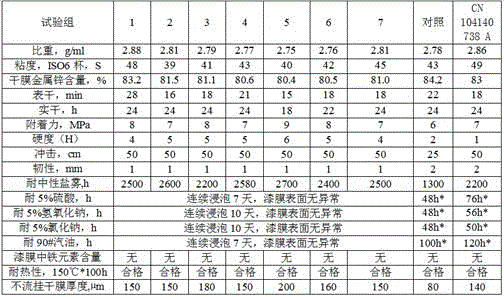

[0156] Table 3: The second component formula ratio (weight percent) of embodiment 8

[0157]

[0158] The preparation method is:

[0159] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com