Method for preparing insoluble dietary fiber from olea europaea pomace

A technology for soluble dietary fiber and olive fruit, applied in the field of food processing, can solve the problem of low utilization rate of waste pomace, and achieve the effects of easy industrial operation, high whiteness and good sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

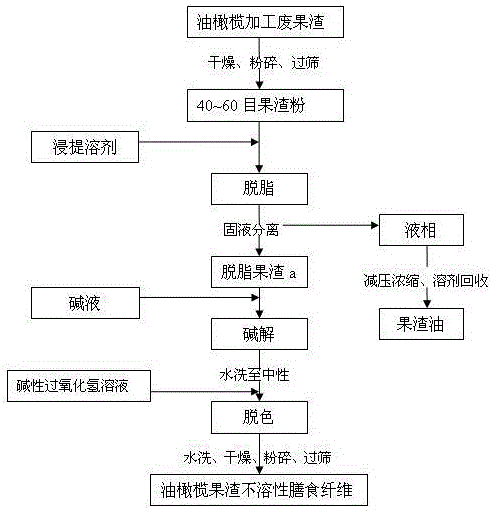

Method used

Image

Examples

Embodiment 1

[0029] (1) Pretreatment: take 500g of olive processing waste pomace, dry at 60°C for 6h~12h, until the moisture content is lower than 8%, crush and pass through a 60-mesh sieve to obtain olive pomace powder;

[0030] (2) Degreasing: take 100g of olive pomace powder obtained in step (1), add petroleum ether according to the ratio of material to liquid 1:5 (g / ml), extract three times, each time for 1h, concentrate and recover petroleum ether, and obtain olive pomace Oil 10.1g and olive degreased pomace a85g;

[0031] (3) Alkaline extraction: take 30 g of olive degreased pomace a in step (2), add a 3% sodium hydroxide solution at a material-to-liquid ratio of 1:20 (g / ml), and perform alkaline extraction at 50°C 1h, filter and wash the obtained solid phase part with water to neutrality, and dry to obtain the filter residue b;

[0032] (4) Decolorization: take the filter residue b obtained in step (3), add an alkaline hydrogen peroxide solution with a pH of 11 and a mass fraction ...

Embodiment 2

[0035] (1) Pretreatment: Take 250g of olive processing waste pomace, dry at 40°C for 6h~12h, until the moisture content is lower than 10%, crush it through an 80-mesh sieve, and obtain olive pomace powder;

[0036] (2) Degreasing: take 80g of olive pomace powder obtained in step (1), add petroleum ether according to the ratio of material to liquid 1:10 (g / ml), extract three times, each time for 2h, concentrate and recover petroleum ether, and obtain olive pomace Oil 7.4g and olive degreased pomace a69.6g;

[0037] (3) Alkaline extraction: take 10 g of olive degreased pomace a in step (2), add 5% sodium hydroxide solution at a material-to-liquid ratio of 1:25 (g / ml), and perform alkaline extraction at 80°C 1.5h, filter and wash the obtained solid phase with water to neutrality, and dry to obtain filter residue b;

[0038] (4) Decolorization: take the filter residue b obtained in step (3), add an alkaline hydrogen peroxide solution with a pH of 12 and a mass fraction of 5% acco...

Embodiment 3

[0041] (1) Pretreatment: Take 100g of olive processing waste pomace, dry at 70°C for 6h~12h, until the moisture content is lower than 5%, crush it through a 60-mesh sieve, and obtain olive pomace powder;

[0042] (2) Degreasing: take 30g of olive pomace powder obtained in step (1), add petroleum ether according to the ratio of material to liquid 1:20 (g / ml), extract three times, each time for 1.5h, concentrate and recover petroleum ether, and obtain olive fruit 2.6g of residual oil and 25.1g of olive degreased pomace;

[0043] (3) Alkaline extraction: take 20 g of olive degreased pomace a in step (2), add 8% sodium hydroxide solution at a material-to-liquid ratio of 1:10 (g / ml), and perform alkaline extraction at 70°C 1h, filter and wash the obtained solid phase part with water to neutrality, and dry to obtain the filter residue b;

[0044] (4) Decolorization: Take the filter residue b obtained in step (3), add an alkaline hydrogen peroxide solution with a pH of 11 and a mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com