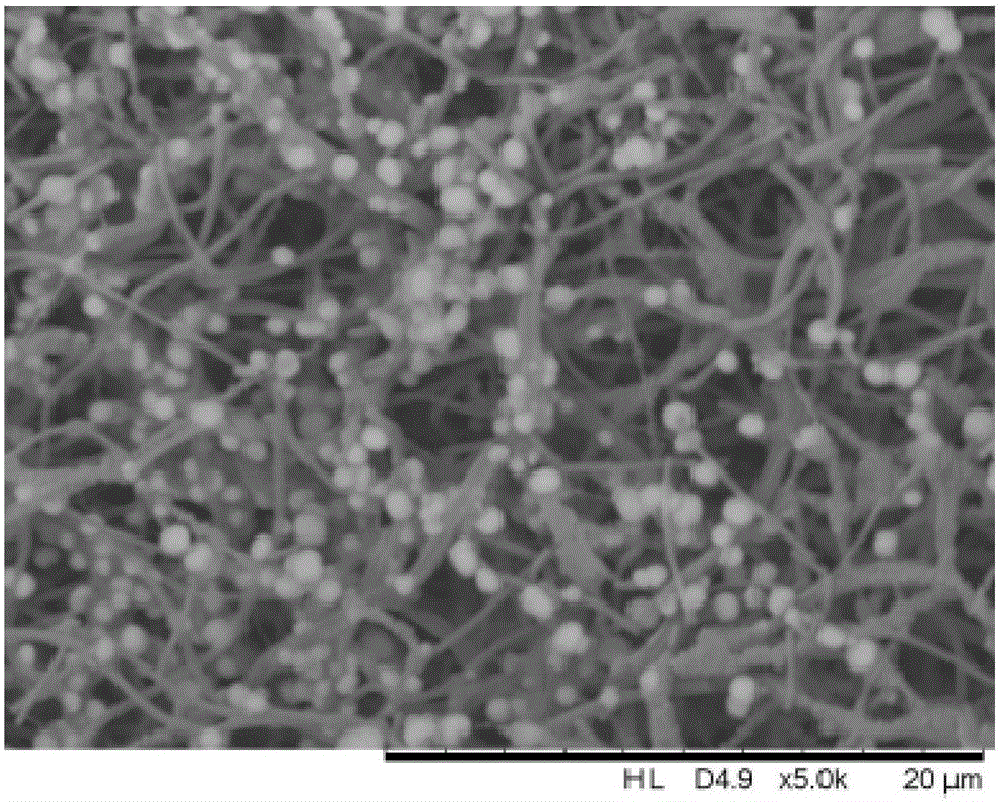

Preparation method for ZnO/perfluoropolymer nanofiber photocatalytic membrane

A technology of perfluoropolymer and nanofiber membrane, which is applied in the field of photocatalysis, can solve the problems of easy degradation of fiber carrier, insufficient coating stability, and inability to control the loading amount, and achieve good photocatalytic performance, controllable loading amount, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of ZnO / perfluoropolymer nanofiber photocatalytic film, comprising the steps of:

[0034] A. Preparation of spinning solution

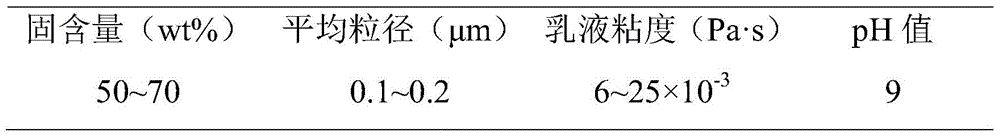

[0035] Take by weighing 5g polyvinyl alcohol (model: 1788, be abbreviated as PVA), utilize distilled water to be mixed with the aqueous solution that mass fraction is 10%; Add polytetrafluoroethylene (PTFE) water dispersion emulsion (solid content is 60wt%) 50g, (equivalent When the total solid content is 35.00%, PVA:PTFE is 1:6) to obtain a mixed solution, then add 20 g of zinc acetate (accounting for 20% of the mass of the mixed solution), and after continuous stirring, stand for defoaming for 12 hours to obtain a spinning solution;

[0036] B. Preparation of precursor nanofiber membrane

[0037] Inject the spinning solution obtained in step A into a 5ml electrospinning syringe device, set the spinning parameters as follows: the voltage is 25KV, the distance between the spinneret and the receiving disc is 10cm, the extrus...

Embodiment 2

[0042] A preparation method of ZnO / perfluoropolymer nanofiber photocatalytic film, comprising the steps of:

[0043] A. Preparation of spinning solution

[0044]Take by weighing 5g polyvinyl alcohol (model: 1788, abbreviated as PVA), be mixed with the aqueous solution that mass fraction is 10%, add polytetrafluoroethylene (PTFE) water dispersion emulsion 50g (solid content is 60wt%), (equivalent to total The solid content is 35.00%, wherein PVA: PTFE is 1:6) to obtain a mixed solution, then add 10 g of zinc acetate (accounting for 10% of the mixed solution mass) and continue to stir evenly, then stand for defoaming for 12 hours to obtain a spinning solution.

[0045] B. Preparation of precursor nanofiber membrane

[0046] The spinning solution obtained in step A was injected into three 5ml electrospinning syringe devices for multi-needle spinning. The spinning parameters are set as follows: the voltage is 20KV, the distance between the spinneret and the receiving disc is 8cm...

Embodiment 3

[0051] A preparation method of ZnO / perfluoropolymer nanofiber photocatalytic film, comprising the steps of:

[0052] A. Preparation of spinning solution

[0053] Take by weighing 2g polyvinyl alcohol (model: 1799), utilize distilled water to be mixed with the aqueous solution that mass fraction is 8%; Add polytetrafluoroethylene (PTFE) aqueous emulsion 26.67g (solid content is 60wt%), (equivalent to total solid content 34.84%, where PVA: PTFE is 1:8), to obtain the mixed solution, then add 5.17g of nano-ZnO powder (nano-ZnO powder accounts for 10% of the mass of the mixed solution), after continuous stirring, stand for defoaming for 12h, to obtain spinning solution;

[0054] B. Preparation of precursor nanofiber membrane

[0055] Inject the spinning solution obtained in step A into three 5ml electrospinning syringe devices, set the spinning parameters as follows: the voltage is 25KV, the distance between the spinneret and the receiving disc is 8cm, the extrusion speed is 6μl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com