Honeycomb integrated low-temperature denitrification catalyst and preparation method thereof

A low-temperature denitration and catalyst technology, applied in the field of denitration catalysts, can solve the problems of the honeycomb monolithic catalyst being difficult to manufacture, the plasticity of the green body being reduced, and the denitration activity being low, and achieving the effects of low production cost, easy operation and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

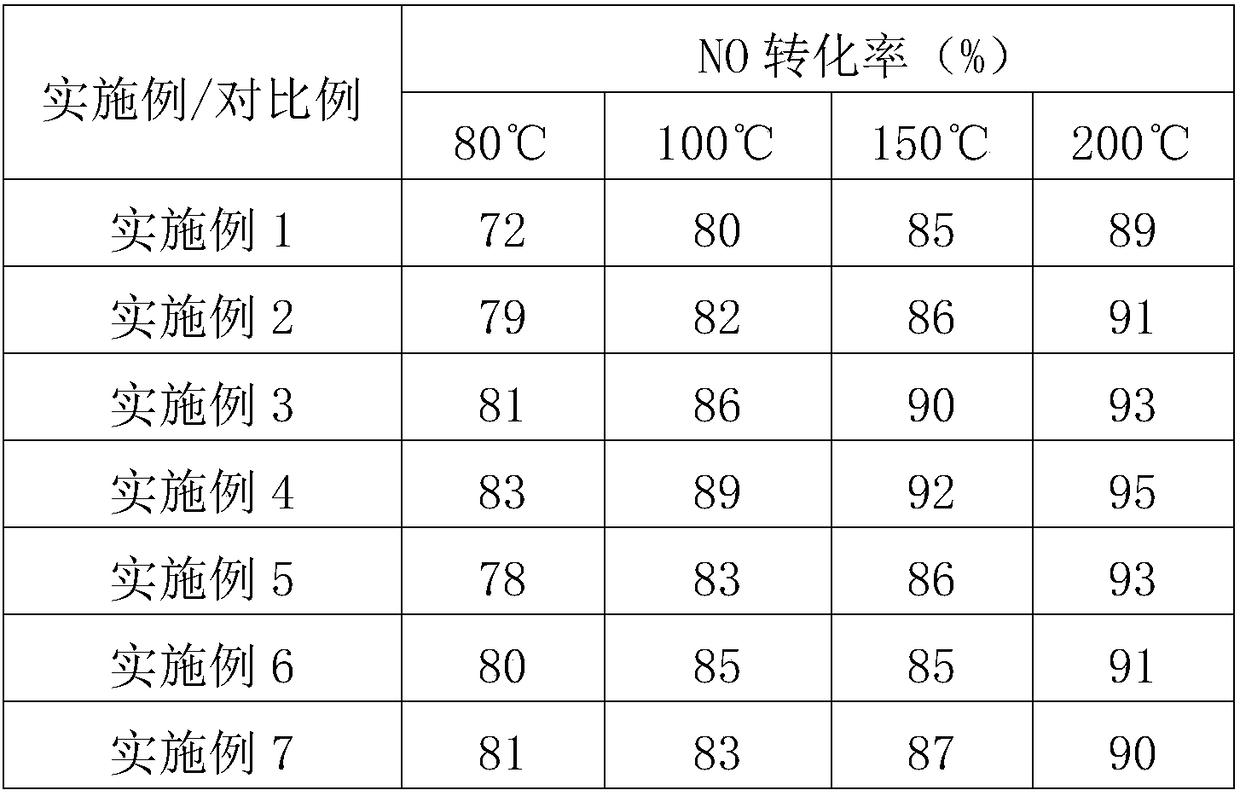

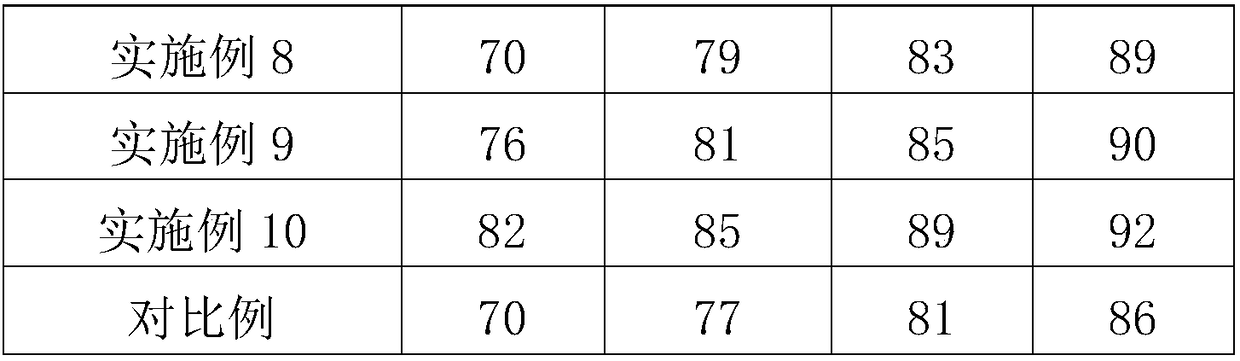

Examples

Embodiment 1

[0031] 1) 537g mass fraction is 50% Mn(NO 3 ) 2 aqueous solution and 163g of Ce(NO 3 ) 3 ·6H 2 O, 48.4g of Fe (NO 3 ) 3 Add it into 1000g of water, stir until dissolved to obtain a metal salt solution;

[0032] 2) Add 1000g of titanium dioxide to the metal salt solution to obtain a suspension, stir the suspension until uniformly dispersed, and heat at 120°C for 6h to obtain a dry catalyst powder;

[0033] 3) Mix 1000g of catalyst dry powder, 40g of aluminum sol with a mass fraction of 60%, 30g of sodium carboxymethylcellulose with a mass fraction of 1%, 15g of Tween-20 and 1800g of water, and stir for 1h to obtain a slurry , the solid content of the slurry is 35%, and the pH value is 3.5;

[0034] 4) adopt the method for vacuum extraction, artificial coating, described slurry is coated on the honeycomb cordierite carrier of 400 order 150mm*150mm*100mm, remove redundant slurry;

[0035] 5) The coated honeycomb cordierite carrier was dried at 120° C. for 4 hours, then he...

Embodiment 2

[0038] 1) 537g mass fraction is 50% Mn(NO 3 ) 2 aqueous solution and 163g of Ce(NO 3 ) 3 ·6H 2 O, 48.4g of Fe (NO 3 ) 3 Add it into 1000g of water, stir until dissolved to obtain a metal salt solution;

[0039]2) Add 1000g of titanium dioxide to the metal salt solution to obtain a suspension, stir the suspension until uniform, adjust its pH to 11 with ammonia water with a mass fraction of 25%, stir for 6 hours, wash, and filter to obtain a catalyst solid precipitation;

[0040] 3) Mix the 1000g of catalyst solid precipitation, 40g of aluminum sol with a mass fraction of 60%, 30g of sodium carboxymethylcellulose with a mass fraction of 1%, 15g of Tween-20 and 1800g of water, and stir for 1h to obtain a slurry material, the solid content of the slurry is 35%, and the pH value is 3.8;

[0041] 4) Apply the slurry to a 400-mesh 150mm*150mm*100mm honeycomb cordierite carrier by vacuum extraction and manual coating to remove excess slurry;

[0042] 5) Dry the coated honeyco...

Embodiment 3

[0045] 1) 537g mass fraction is 50% Mn(NO 3 ) 2 aqueous solution and 163g of Ce(NO 3 ) 3 ·6H 2 O, 48.4g of Fe (NO 3 ) 3 Add it into 1000g of water, stir until dissolved to obtain a metal salt solution;

[0046] 2) Add 1000g of titanium dioxide to the metal salt solution to obtain a suspension, stir the suspension until uniform, adjust its pH to 10 with ammonia water with a mass fraction of 25%, and conduct a hydrothermal reaction at 180°C in a reactor 6h, washing, filtering to obtain catalyst solid precipitation;

[0047] 3) Mix the 1000g of catalyst solid precipitation, 40g of aluminum sol with a mass fraction of 60%, 30g of sodium carboxymethylcellulose with a mass fraction of 1%, 15g of Tween-20 and 1800g of water, and stir for 1h to obtain a slurry material, the solid content of the slurry is 31%, and the pH value is 3.6;

[0048] 4) adopt the method for vacuum extraction, artificial coating, described slurry is coated on the honeycomb cordierite carrier of 400 ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com