Advanced treatment method for electroplating wastewater

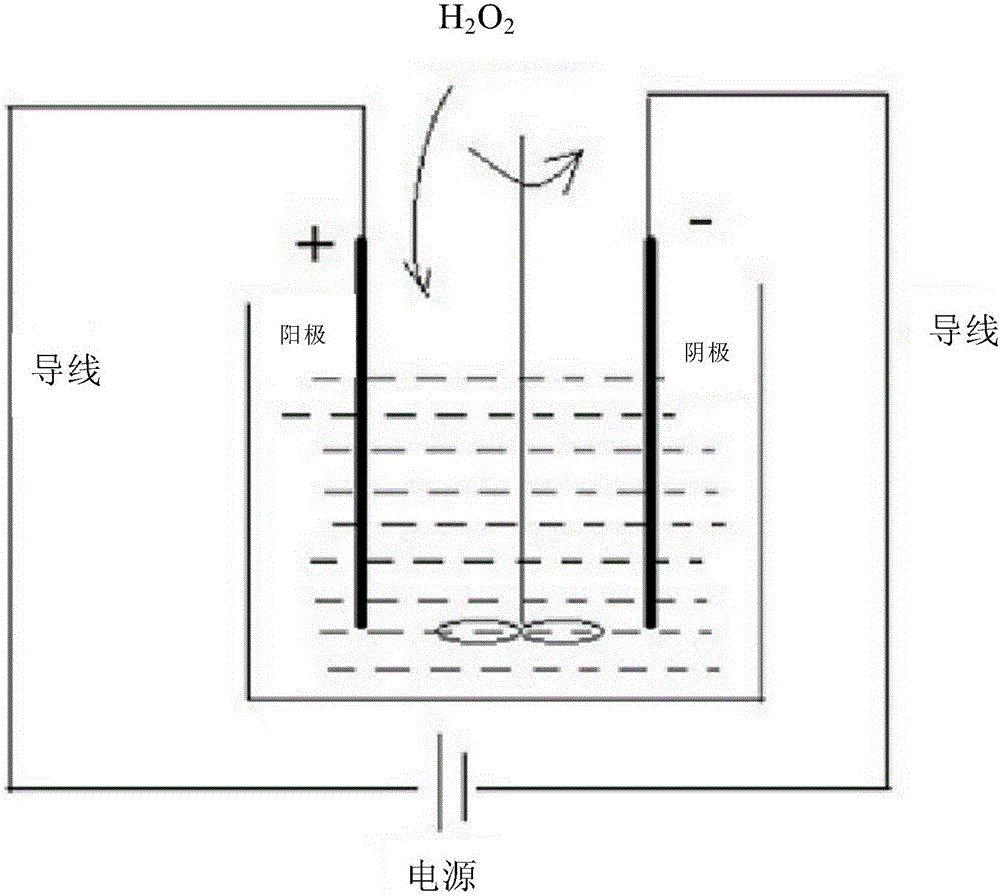

A technology for advanced treatment and electroplating wastewater, applied in metallurgical wastewater treatment, electrochemical water/sewage treatment, water/sewage treatment, etc. It can solve the problems of fluctuating pretreatment effect, high labor cost, high current density, and achieve charge utilization efficiency. High, low operating cost, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

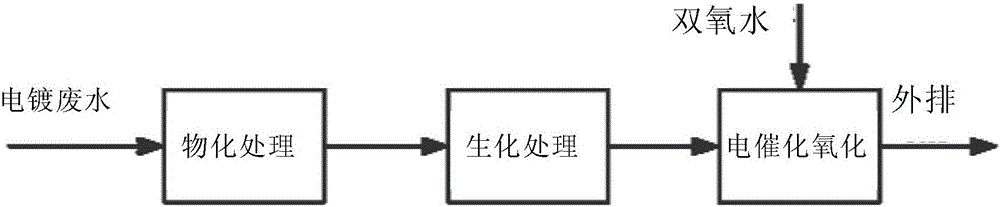

[0039] The electroplating wastewater in an electroplating park has a water volume of 2,000 tons / day. After physical, chemical and biochemical two-stage treatment, the COD is between 60-70mg / L. Electrocatalytic oxidation is used for advanced treatment. Titanium-coated ruthenium-iridium anodes are used, and the ruthenium content is 70%. , the cathode is made of stainless steel, and the current density is 200A / m 2 . After treatment, the COD is reduced to less than 50mg / L, reaching the special discharge limit of the "Electroplating Pollutant Discharge Standard", and the cost per ton of water is about 0.2-0.4 yuan.

Embodiment 2

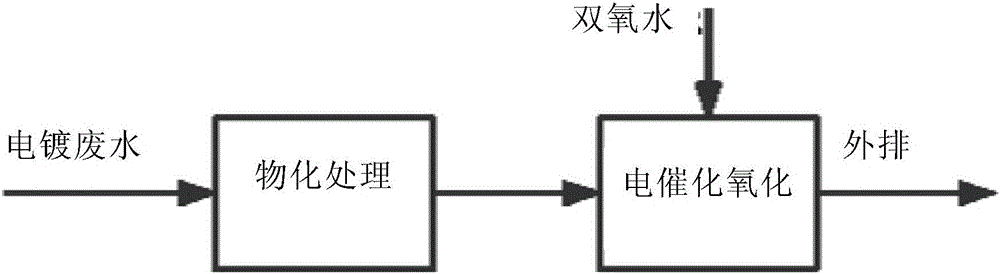

[0041] The waste water of an electroplating factory has a water volume of 80 tons / day. After physical and chemical treatment, the COD is between 100-120mg / L. Electrocatalytic oxidation is used for advanced treatment. Titanium-coated ruthenium-iridium anodes are used, with a ruthenium content of 75%, and stainless steel is used for the cathode. The current density is 220A / m 2 . After treatment, the COD is reduced to less than 80mg / L, reaching the "Electroplating Pollutant Discharge Standard", and the cost per ton of water is about 0.4-0.8 yuan.

Embodiment 3

[0043] Wastewater from an electroplating factory, the water volume is 50 tons / day, after physical and chemical treatment, the COD is between 130-150mg / L, and the advanced treatment is carried out by electrocatalytic oxidation, using titanium-coated ruthenium-iridium anode, the ruthenium content is 80%, and the cathode uses graphite. The current density is 230A / m 2 . After treatment, the COD is reduced to less than 80mg / L, reaching the "Electroplating Pollutant Discharge Standard", and the cost per ton of water is about 1.0-1.4 yuan.

[0044] It can be seen that after the advanced treatment of the present invention, the COD of electroplating wastewater has been further significantly reduced, and the cost has been greatly reduced, which has dual social and economic benefits.

[0045] In summary, by optimizing the electrode material, the present invention can also have good catalytic activity in the case of a flat electrode structure without adding fillers, and can still catalyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com