Method for preparing oxygen deficiency semiconductor nitrogen dioxide gas-sensitive coating

A nitrogen dioxide and semiconductor technology, used in measuring devices, instruments, material analysis by electromagnetic means, etc., can solve the problems of aging, inconvenient use and application limitations of gas sensors, and achieve absorption, fast response speed, Controlled effect of coating porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

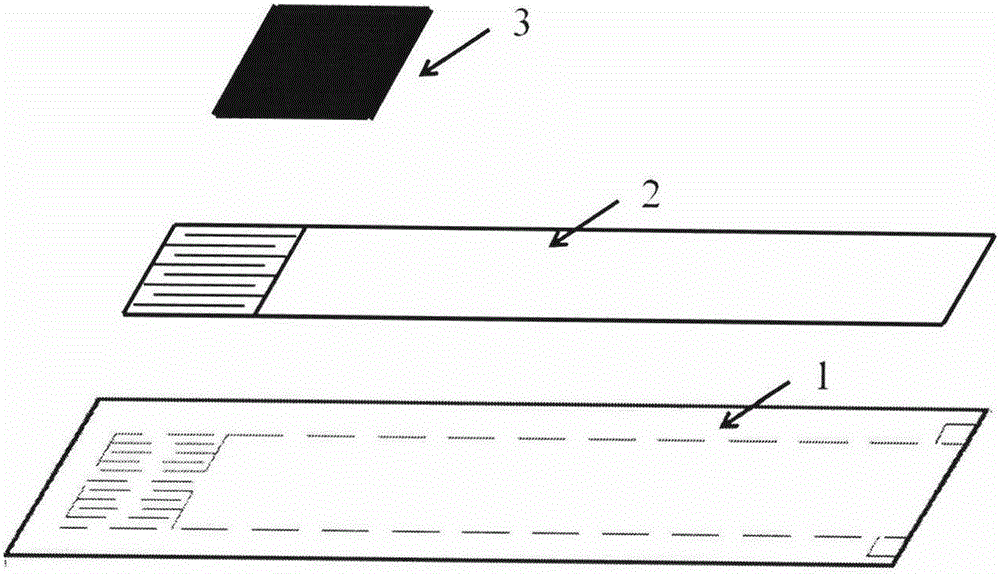

[0051] 1. Use alumina as the insulating substrate 1, wash 30×20×1mm alumina flakes in deionized water and ethanol in turn, and assist with ultrasonic cleaning for 5 minutes, and dry at 80°C for later use.

[0052] 2. Using the method of vacuum coating and metal mask pattern, first prepare a layer of chromium with a thickness of 0.3 μm to improve the bonding strength, and then vapor-deposit a layer of 0.5 μm gold to obtain the interdigitated electrode 2 .

[0053] 3. Weigh 22.14g crystalline zinc acetate Zn (CH 3 COO)·2H 2 O, dissolved in 500ml deionized water, using magnetic stirring to obtain a colorless and transparent solution precursor.

[0054] 4. Using the solution precursor plasma spraying method, spray the ZnO coating directly above the interdigitated electrode, the spraying distance is 75mm, the plasma generation gas is 40ml / min argon and 2ml / min hydrogen, the substrate temperature is room temperature, and the spraying power is 25KW, a ZnO coating with a thickness o...

Embodiment 2

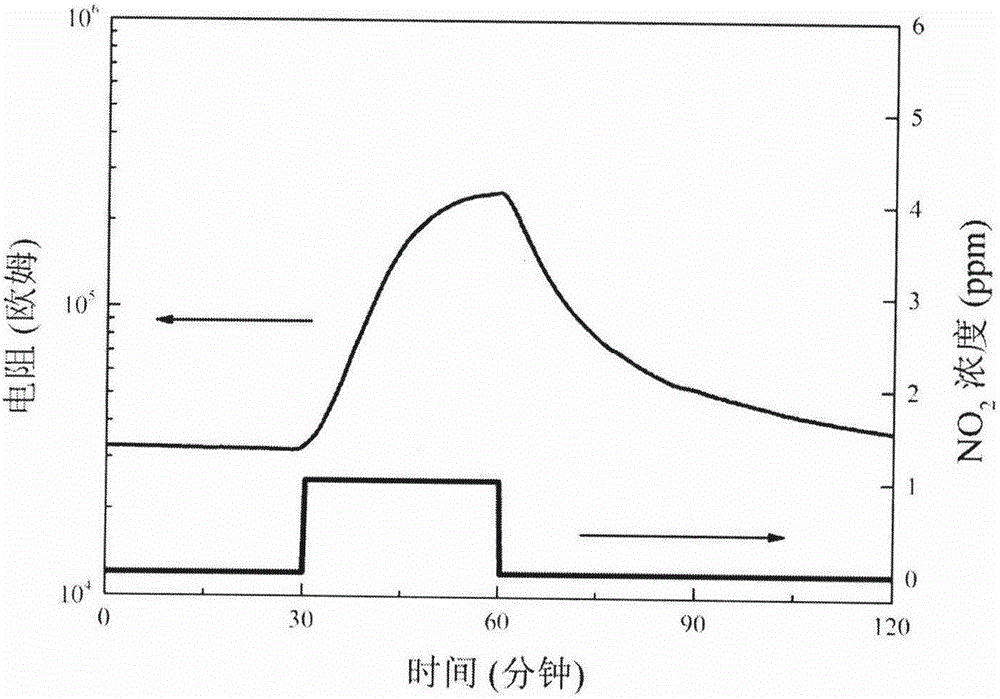

[0060] The difference between this embodiment and embodiment 1 is: in step 3, take by weighing 30.42g crystalline ammonium tungstate, H 40 N 10 o 41 W 12 ·xH 2 O was dissolved in 500ml deionized water, and the colorless and transparent solution precursor was obtained by magnetic stirring; in step 4, the solution plasma spraying method was used to spray WO on the interdigitated electrode 2. 3 Coating, the spraying distance is 100mm, the plasma generation gas is 50mL / min argon and 4mL / min hydrogen, the substrate temperature is 50 degrees, the spraying power is 27KW, and the thickness of 10.0μm is obtained on the interdigitated electrode. 3 coating; the concentration of oxygen defects was 30%, and in step 8, the coating pairs 0.2ppm and 0.5ppmNO 2 When , the sensitivity of the sensor is 3.1 and 5.6 respectively.

Embodiment 3

[0062] The difference between this embodiment and Example 1 is: in step 3, 50.28g crystalline tin dichloride (SnCl 2 ) was dissolved in 500ml deionized water, and a colorless and transparent solution precursor was obtained by magnetic stirring; in step 4, the solution plasma spraying method was used to spray SnO directly above the interdigitated electrode 2 Coating, the spraying distance is 120mm, the plasma generation gas is 40ml / min argon and 3ml / min hydrogen, the substrate temperature is 200 degrees, the spraying power is 26KW, and the SnO with a thickness of 5.0μm is obtained on the interdigitated electrode 2 coating; the concentration of oxygen deficiency was 17%; in step 8, the coating was applied to 2ppm and 5ppmNO 2 , the sensitivities of the sensors were 8.5 and 14.9, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com