Method for extracting albumin glue from pig dung residues and preparing biomass energy

A technology of biomass energy and protein glue, which is applied in the preparation methods of peptides, biochemical equipment and methods, microorganisms, etc., can solve problems such as high cost and pollute the environment, and achieve low production cost, short processing time, and anti-crushing performance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation materials and facilities: 5 sets of self-made stainless steel barrels 1#, 2#, 3#, 4#, 5#, volume 0.86m 3 , 1m in diameter, 1.1m in height, equipped with a stirring and scraping device with a power of 375w and 220V, and a heating device installed at the bottom; a microporous aeration pump with a power of 150w and 220V; MES-57 automatic frequency conversion temperature and pressure dual control 1 set of microwave digestion / extraction instrument; 1 set of ME6 microwave COD rapid tester; 1 set of 750w vacuum suction filter; 1 set of AKRF series biomass molding fuel granulator; 1 set of MJ-800 series hammer mill; One set of HWIR200A small conveyor belt drying equipment; several beakers, measuring cups, reagents, and trays.

[0038] Take 500Kg of pig manure samples with a moisture content of 96.5% and put them into the 1# bucket, start stirring, add 20Kg of urban sludge residue with a moisture content of 75%, stir at a constant speed for 6 hours, and the stirring ...

Embodiment 2

[0049] Take 1000Kg of pig manure residue from a farming and animal husbandry company in Hengtian, Hunan, with a water content of 96.5%; take 50Kg of urban sludge from an urban sewage treatment plant in Hengyang County, with a water content of 75%. Take 100Kg of landscaping residue dry branches on the spot. Test according to the procedures and methods described in Example 1, add 2.1Kg of self-made modified digestive enzymes; obtain protein glue 11.85Kg, measure moisture content 87.5%, protein content 39.76%, seal with barrels. The hydrolyzate was filtered and dehydrated with a vacuum filter to obtain 61.7Kg of dry dung residue with a moisture content of 47.5%. See Table 3 for specific indicators.

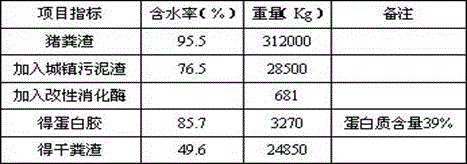

[0050] Table 3 List of indicators of pig manure treatment process

[0051]

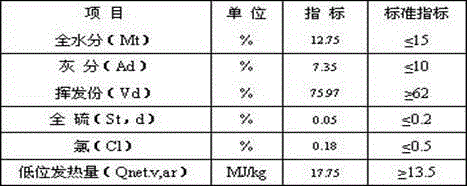

[0052] Use the MJ-800 series hammer mill to crush 100Kg of dry branches and 61.7Kg of dry dung residue respectively. After stirring, add 11.85Kg of protein glue, stir for 10 minutes, and send the materi...

Embodiment 3

[0057] Take 200Kg of pig manure residue from a farm in Loudi, Hunan Xinwufeng Group, with a water content of 95.5%; take 30Kg of urban sludge from a sewage treatment plant in Changsha County, with a water content of 78.5%. Dried peanut shells 50Kg.

[0058] Test according to the procedures and methods described in Example 1, add 0.46Kg of self-made modified digestive enzymes; obtain protein glue 3.5Kg, measure moisture content 83.5%, protein content 42.6%, seal with barrel. The hydrolyzate was filtered and dehydrated with a vacuum filter to obtain 27.8Kg of dry dung residue with a moisture content of 48.5%. See Table 5 for specific indicators.

[0059] Table 5 List of indicators of pig manure treatment process

[0060]

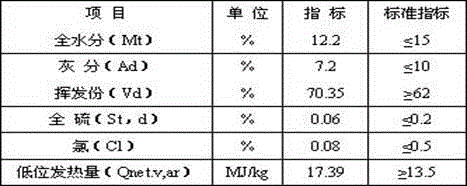

[0061] Use the MJ-800 series hammer mill to crush 50Kg of dried peanut shells and 27.8Kg of dried feces respectively. After stirring, add 3.5Kg of protein glue, stir for 10 minutes, and send the materials to the HWIR200A small conveyor belt drying equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com