Resin concrete for quick maintenance of bridge expansion joints

A resin concrete and expansion joint technology, which is applied in the engineering field, can solve the problems such as the difficulty of fast and durable replacement of expansion joints, single concrete material, secondary damage, etc., to delay or inhibit the oxidation process, and to achieve excellent impact toughness. , the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

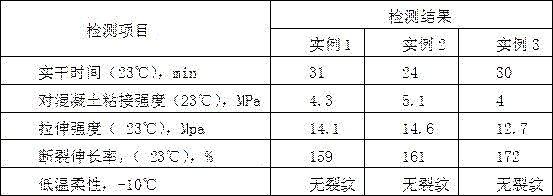

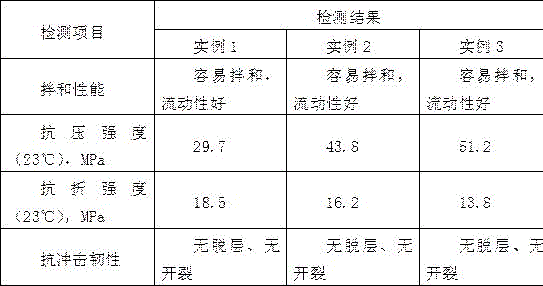

Embodiment 1

[0030] The weight content of each component in the expansion joint rapid repair resin concrete is:

[0031] Synthetic resin 50kg, mineral material 50kg.

[0032] Among them, the synthetic resin is composed of component A: the proportion of component A is as follows, including hard monomer methyl methacrylate 19.5kg, hard monomer styrene 0.73kg, soft monomer butyl methacrylate 9.76kg, soft monomer acrylic acid - 2-ethylhexyl ester 2.44kg, crosslinking monomer trimethylolpropane triacrylate 1.71kg, prepolymer polyether polyurethane diacrylate 12.2kg, prepolymer bisphenol A epoxy diacrylate 1.46 kg, accelerator N,N-dimethylaniline 0.49kg, coupling agent γ-propylmethacrylate trimethoxysilane 0.24kg, oxygen inhibitor melting point 55°C paraffin 0.17kg, polymerization inhibitor 4-methoxy Base phenol 0.02kg, defoamer BYK-0880.05kg.

[0033] Synthetic resin component B: 50% dibenzoyl peroxide 1.23kg.

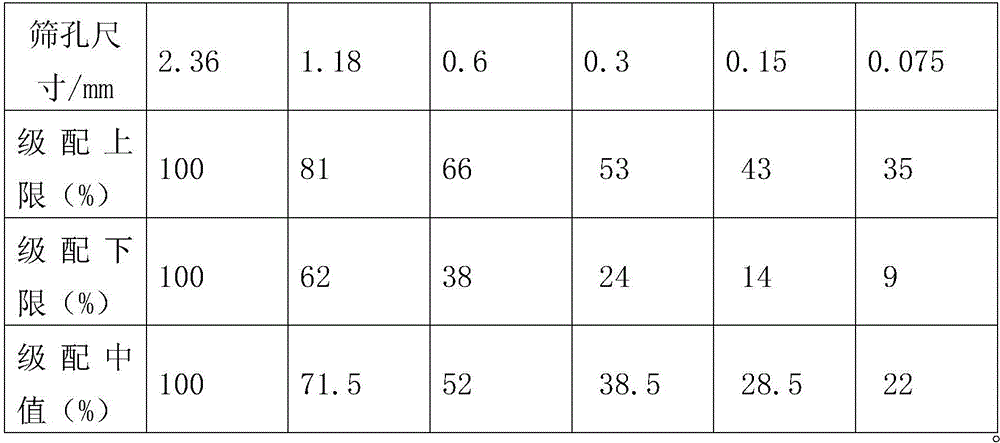

[0034] Among them, the mineral material is composed of: basalt 32.5kg, titanium ...

Embodiment 2

[0044] The weight content of each component in the expansion joint rapid repair resin concrete is:

[0045] Synthetic resin 30kg, mineral material 70kg.

[0046]The synthetic resin is composed of component A: hard monomer methyl methacrylate 10.19kg, hard monomer ethyl methacrylate 1.46kg, hard monomer styrene 0.44kg, soft monomer butyl methacrylate 4.36kg, Soft monomer butyl acrylate 1.46kg, soft monomer 2-ethylhexyl acrylate 3.35kg, prepolymer polyether polyurethane diacrylate 5.83kg, prepolymer bisphenol A epoxy diacrylate 1.46kg, Accelerator N,N-dimethylaniline 0.29kg, coupling agent γ-propylmethacrylate trimethoxysilane 0.15kg, oxygen inhibitor polyethylene wax 0.10kg, polymerization inhibitor 4-methoxyphenol 0.01 kg, defoamer BYK-0880.03kg.

[0047] Synthetic resin component B: 0.87kg of 50% dibenzoyl peroxide.

[0048] The mineral materials are composed of: 56kg of quartz sand and 14kg of kaolin.

[0049] The specific preparation method is as follows:

[0050] Step...

Embodiment 3

[0059] The weight content of each component in the expansion joint rapid repair resin concrete is:

[0060] Synthetic resin 15kg, mineral material 85kg.

[0061] The synthetic resin is composed of component A: hard monomer methyl methacrylate 4.39kg, hard monomer ethyl methacrylate 1.46kg, hard monomer styrene 0.22kg, soft monomer butyl methacrylate 2.93kg, Soft monomer isobornyl acrylate 0.22kg, prepolymer aliphatic polyurethane diacrylate 4.39kg, bisphenol A epoxy diacrylate 0.73kg, accelerator N,N-dimethyl-p-toluidine 0.15kg, coupling Agent γ-propylmethacrylate trimethoxysilane 0.07kg, oxygen inhibitor polyethylene wax 0.05kg, polymerization inhibitor 4-methoxyphenol 0.01kg, defoamer BYK-0880.01kg.

[0062] Synthetic resin component B: 0.37kg of 50% dibenzoyl peroxide.

[0063] The mineral materials are composed of: 76.5kg of quartz sand and 8.5kg of kaolin.

[0064] The specific preparation method is as follows:

[0065] Step 1: Preparation of component A: (1) Feed mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com