Preparation method of glimepiride tablets

A technology of urea tablets and povidone, which is applied in the field of medicine and can solve problems such as low bioavailability, harsh conditions, and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

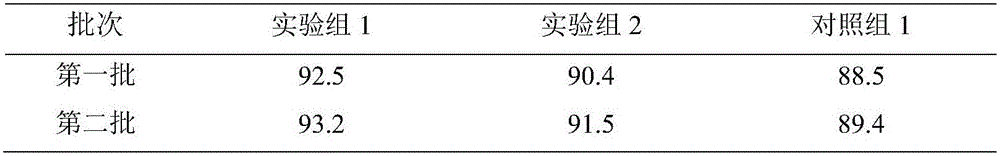

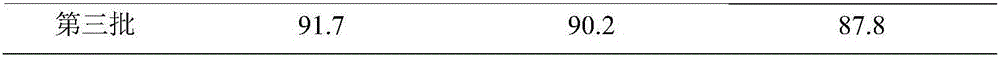

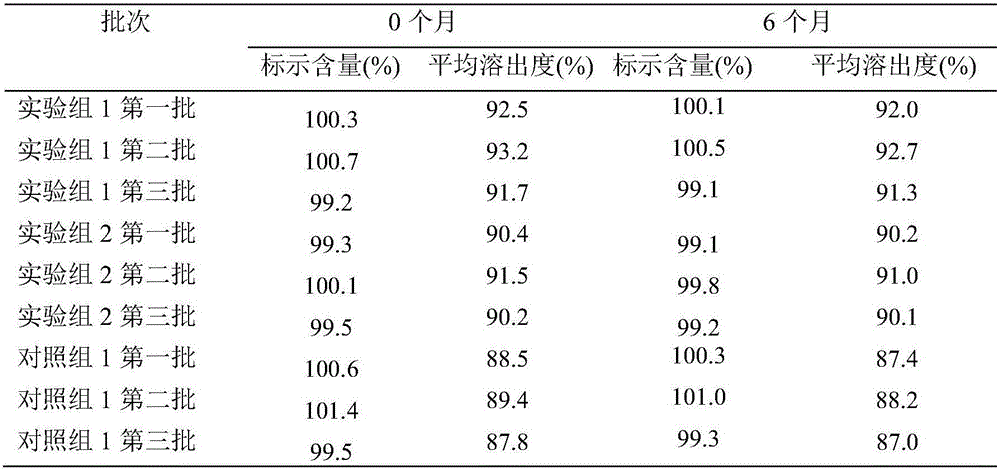

Examples

preparation example Construction

[0044] The preparation method of the glimepiride tablet announced by the patent of the present invention mainly relies on two ways to improve the dissolution rate of the main drug, one is micronization of the glimepiride raw material drug; the other is adding auxiliary materials that help to improve the dissolution rate, Specifically, adding a hydrophilic binder povidone and increasing the amount of water-soluble excipient lactose. The glimepiride raw material drug is pulverized to prepare glimepiride powder with a particle size of less than 10 μm by means of an airflow pulverization method.

[0045] The present invention also provides a glimepiride tablet prepared by the above method, the glimepiride tablet components include glimepiride raw material drug, lactose, povidone, sodium carboxymethyl starch, microcrystalline cellulose, stearin Magnesium acid magnesium, glimepiride raw material medicine, lactose, povidone, carboxymethyl starch sodium, microcrystalline cellulose, ma...

Embodiment 1

[0061] Preparation Method Ⅰ of Glimepiride Tablets (Experimental Group 1)

[0062] Micropowder the glimepiride raw material to below 10 μm, weigh 2kg of the glimepiride raw material, 55kg of lactose, 5.2kg of sodium carboxymethyl starch I (internal addition), 0.4kg of povidone, and 0.25kg of microcrystalline cellulose, Carboxymethyl starch sodium II (external addition) 1.9kg, magnesium stearate 0.325kg, glimepiride micropowder, lactose, carboxymethyl starch sodium I (internal addition) were added to the wet granulator and mixed for 20-30 minutes to obtain Glide meurea mixture;

[0063] Add povidone into 9.6kg water and dissolve to prepare 4% povidone aqueous solution (W / W);

[0064] Add 4% povidone aqueous solution to make soft material in the wet granulator, add 14 mesh screens to granulate with a swinging granulator, and dry the granules with a fluidized bed;

[0065] The dried granules are sized with 20 meshes, added with microcrystalline cellulose, sodium starch glycolat...

Embodiment 2

[0067] Glimepiride Tablets Preparation Method II (Experimental Group 2)

[0068] Micropowder the glimepiride raw material to below 10 μm, weigh 2kg of the glimepiride raw material, 55kg of lactose, 5.2kg of sodium carboxymethyl starch I (internal addition), 0.4kg of povidone, and 0.25kg of microcrystalline cellulose, Carboxymethyl starch sodium II (external addition) 1.9kg, magnesium stearate 0.325kg, glimepiride micropowder, lactose, carboxymethyl starch sodium I (internal addition) were added to the wet granulator and mixed for 20-30 minutes to obtain Glide meurea mixture;

[0069] Add povidone to 9.6kg of 75% ethanol (W / W) solution and dissolve to prepare 4% povidone ethanol solution (W / W);

[0070] Add 4% povidone ethanol solution to the wet granulator to make soft materials, add 14 mesh screens to granulate with a swing granulator, and dry the granules with a fluidized bed;

[0071] The dried granules are sized with 20 meshes, added with microcrystalline cellulose, sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com