Method for producing aluminum oxide by means of granulating and sintering of low-grade bauxite

A low-grade bauxite and bauxite technology, applied in the field of smelting, can solve the problems of high production cost, complex and huge production system, complicated process flow, etc., and achieves reduction of production cost and investment in plant construction, and obvious economic benefits. , the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

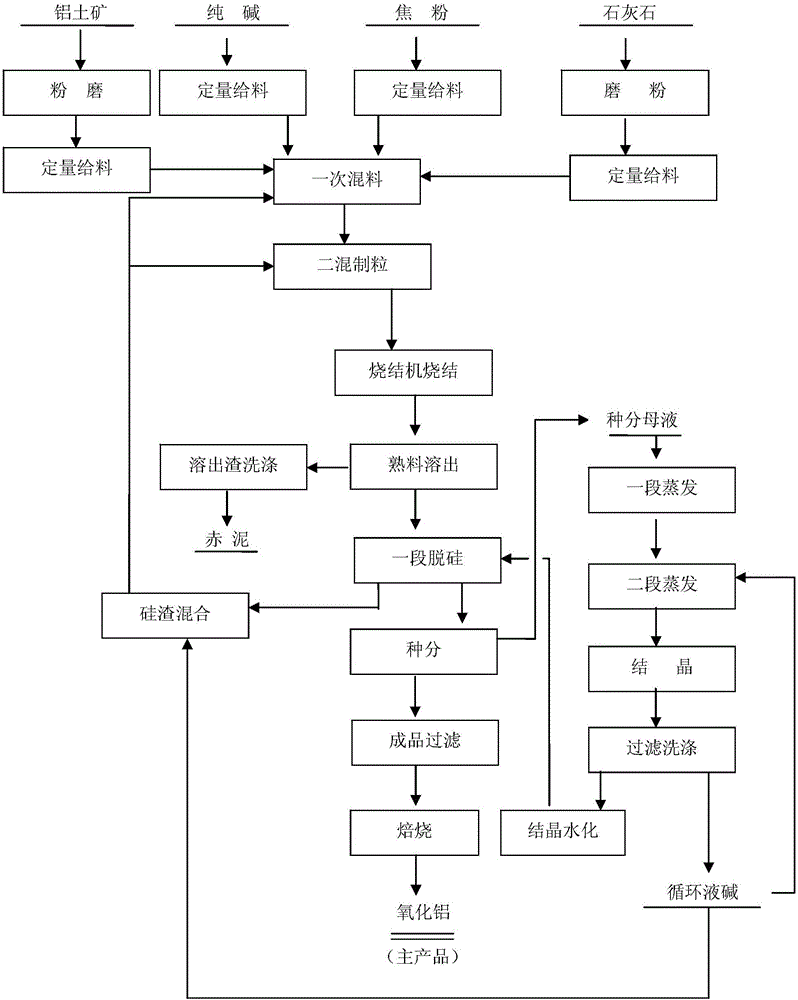

Image

Examples

Embodiment 1

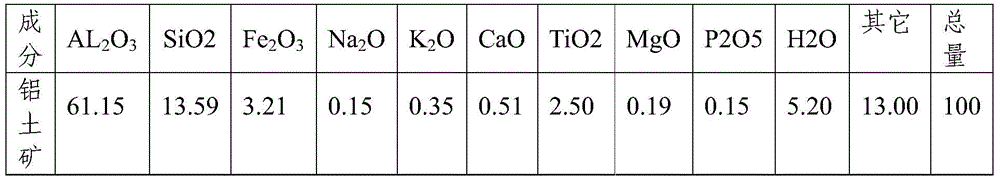

[0037] Table 1: Bauxite Composition

[0038]

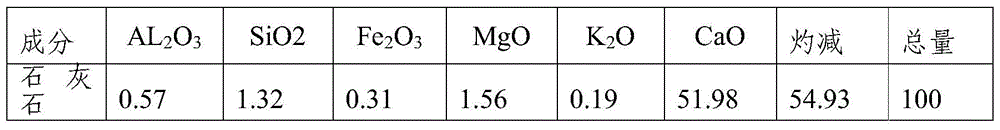

[0039] Table 2: Limestone Composition

[0040]

[0041] First, crush bauxite (composition as shown in Table 1) and limestone (composition as in Table 2) to 2-5 mm respectively, then grind them to a particle size of -0.074 mm and account for more than 85%, and crush the coke powder to 1-5 mm. 3mm. Then fully mix bauxite powder, limestone powder, coke powder, and soda ash powder according to the mass ratio of dry powder: bauxite 35: limestone 26: soda ash 6: coke powder 8, and then prepare lye, which is a circulating sodium aluminate solution , the concentration is Na 2 O510g / L, αk=14, the batching moisture that obtains is 30%, and alkali ratio is 1, and calcium ratio is 2.

[0042] Put the prepared material into the mixer for the first mixing, and the first mixed material enters the secondary mixer, and the secondary mixer machine is sprayed with lye at the same time, and the amount is 3 / 17 of the ingredient amount; The g...

Embodiment 2

[0053] Table 3: Bauxite composition

[0054]

[0055] First, crush bauxite (composition as shown in Table 3) and limestone (composition as in Table 2) to 2-5 mm respectively, then grind them to a particle size of -0.074 mm and account for more than 85%, and crush the coke powder to 1-5 mm. 3mm. Then bauxite powder, limestone powder, coke powder, and soda ash powder are fully mixed according to the ratio of bauxite 40: limestone 30: soda ash 10: coke powder 10 according to the dry powder mass ratio, and the concentration of the lye is Na 2 O550g / L, αk=20, the batching moisture that obtains is 28%, and alkali ratio is 1, and calcium ratio is 2.

[0056] Put the prepared material into the mixing machine for the first mixing, and the mixed material enters the secondary mixing machine, and the secondary mixing machine sprays the lye that accounts for 13 / 87 of the batching lye at the same time. The granulation is carried out in the mixer, and the particle distribution is 3-8mm....

Embodiment 3

[0064] Table 4: Bauxite composition

[0065]

[0066] First, crush bauxite (composition as shown in Table 4) and limestone (composition as in Table 2) to 2-5 mm respectively, then grind them to a particle size of -0.074 mm and account for more than 85%, and crush the coke powder to 1-5 mm. 3mm. Then bauxite powder, limestone powder, coke powder, and soda ash powder are fully mixed according to the dry powder mass ratio of bauxite 45: limestone 35: soda ash 15: coke powder 12%, and then prepare lye with a concentration of Na 2 O550g / L, αk=20, and the lye is divided into two parts by volume, and the distribution ratio is 90:10. The ingredient moisture is 26%, the alkali ratio is 1, the calcium ratio is 2, and the coke powder ratio is 12%.

[0067] Put the prepared material together with 90% lye into the mixer for the first mixing, and the first mixed material enters the secondary mixer, and the secondary mixer sprays the remaining 10% lye at the same time , Carry out granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com