Comprehensive environment-friendly shell powder coating

A shell powder and comprehensive technology, which is applied in the field of comprehensive environmental protection shell powder coatings, can solve the problems of resource waste, environmental and human harm, and achieve the effects of not easy aging and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A comprehensive environmental protection shell powder coating, take 325 mesh shell powder 90kg, cyclodextrin inclusion compound 10kg, barium sulfate 10kg, chitosan 10kg, hydroxypropyl methylcellulose HPMC0.5kg, redispersible latex powder 0.4kg, 0.4kg of polyvinyl alcohol powder, 2kg of sodium bentonite and 0.3kg of wood fiber are put into a mixer and stirred for 25-30 minutes to obtain the finished product.

Embodiment 2

[0019] A comprehensive environmental protection shell powder coating, take 325 mesh shell powder 95kg, cyclodextrin inclusion compound 15kg, barium sulfate 15kg, chitosan 15kg, hydroxypropyl methylcellulose HPMC0.6kg, redispersible latex powder 0.8kg, 0.8kg of polyvinyl alcohol powder, 3kg of sodium bentonite and 0.2kg of wood fiber are put into a mixer and stirred for 25-30 minutes to obtain the finished product.

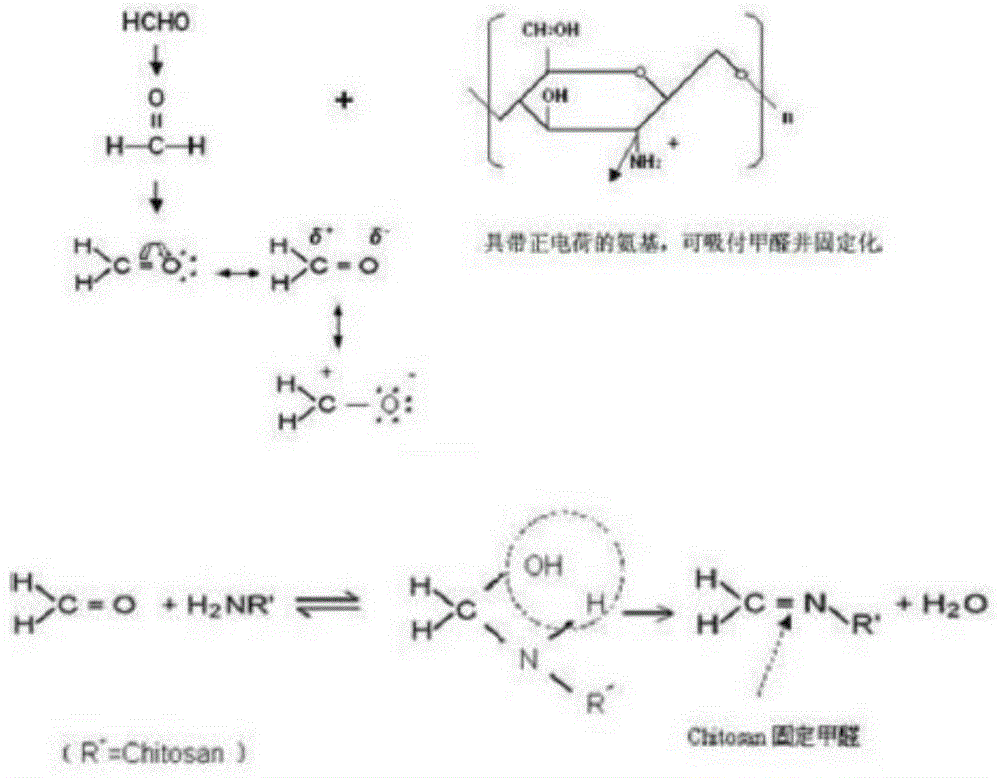

[0020] Chitosan (Chitosan), which has a special structure and a strong reactive amine group (-NH2), can chemically react with many gaseous harmful substances, so for formaldehyde, TVOC (total organic release amount), chitosan can capture and eliminate it, and finally achieve the purpose of purifying the air.

[0021] Chitosan is made from the chitin of shrimp and crab shells, and its structure is similar to polysaccharides. Its monomer structure is special, and its multiple highly polar functional groups enable it to collect formaldehyde molecules released from bui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com