Novel wet-mixed mortar

A wet-mixed mortar, a new type of technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as high cost and difficult production control, achieve long opening time, improve construction efficiency, shorten The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

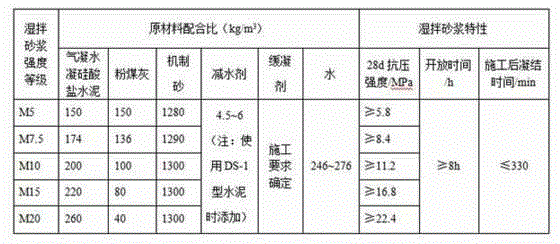

[0039] Configure M5 grade wet-mixed mortar

[0040] In this example, the components of the wet-mixed mortar are:

[0041] Air-setting hydraulic Portland cement: 150kg / m 3

[0042] Fly ash: 150kg / m 3

[0043] Machine-made sand: 1300kg / m 3

[0044] Water: 230kg / m 3

[0045] Water reducer: 4.5kg / m 3

[0046] Retarder: 0.40kg / m 3 .

[0047] The air-setting hydraulic Portland cement used is DS-1 type cement, and its ingredients include ordinary Portland cement, slaked lime, bentonite, fly ash, air-entraining agent and hydroxyethyl cellulose ether, and its weight ratio is as follows Down:

[0048] Ordinary Portland cement: 85%

[0049] Slaked lime: 5.015%

[0050] Bentonite: 1.9%

[0051] Fly ash: 8%

[0052] Air-entraining agent: 0.07%

[0053] Hydroxyethyl cellulose ether: 0.015%.

[0054] The slaked lime is calcareous slaked lime, and in the slaked lime, the sum of the mass percentages of calcium oxide and magnesium oxide is 85%.

[0055] The bentonite is sodiu...

Embodiment 2

[0064] Configure M5 grade wet-mixed mortar

[0065] In this example, the components of the wet-mixed mortar are:

[0066] Air-setting hydraulic Portland cement: 150kg / m 3

[0067] Fly ash: 150kg / m 3

[0068] Machine-made sand: 1300kg / m 3

[0069] Water: 242kg / m 3

[0070] Retarder: 0.40kg / m 3 .

[0071] The air-setting hydraulic Portland cement used is DS-2 type cement, and its components include slag Portland cement, slaked lime, bentonite, fly ash, air-entraining agent, silica fume and polyvinyl alcohol, and their weight distribution For example:

[0072] Slag Portland cement (20% slag content in cement): 91.995%

[0073] Slaked lime: 1.8%

[0074] Bentonite: 2%

[0075] Fly ash: 4%

[0076] Silica fume: 0.1

[0077] Air-entraining agent: 0.005%

[0078] Polyvinyl alcohol: 0.1%

[0079] The slaked lime is calcareous slaked lime, and in the slaked lime, the sum of the mass percentages of calcium oxide and magnesium oxide is 88.5%.

[0080] The bentonite is s...

Embodiment 3

[0089] Configure M7.5 grade wet-mixed mortar

[0090] Air-setting hydraulic Portland cement: 174kg / m 3

[0091] Fly ash: 136kg / m 3

[0092] Machine-made sand: 1290kg / m 3

[0093] Water: 240kg / m 3

[0094] Retarder: 0.42kg / m 3 .

[0095] The air-setting hydraulic Portland cement used is DS-2 cement, which includes pozzolanic Portland cement, slaked lime, bentonite, fly ash, air-entraining agent, silica fume and polyvinyl alcohol , and their weight ratio is as follows:

[0096] Portland pozzolanic cement (23% pozzolanic content in cement): 95%

[0097] Slaked lime: 3%

[0098] Bentonite: 1%

[0099] Fly ash: 0%

[0100] Silica fume: 0.94%

[0101] Air-entraining agent: 0.01%

[0102] Polyvinyl alcohol: 0.05%.

[0103] The slaked lime is calcareous slaked lime, and in the slaked lime, the sum of the mass percentages of calcium oxide and magnesium oxide is 88%.

[0104] The bentonite is sodium-based bentonite with a water absorption rate of 320% and a sieve residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com