Boron nitride reinforced iron runner material

An enhanced boron nitride technology, applied in the field of boron nitride enhanced iron trench material and metal smelting, can solve the problems of poor thermal shock resistance, no corrosion resistance, limited carbon whisker generation, etc., and achieve anti-slag erosion Improved performance and thermal shock resistance, strong chemical corrosion resistance, and enhanced slag erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

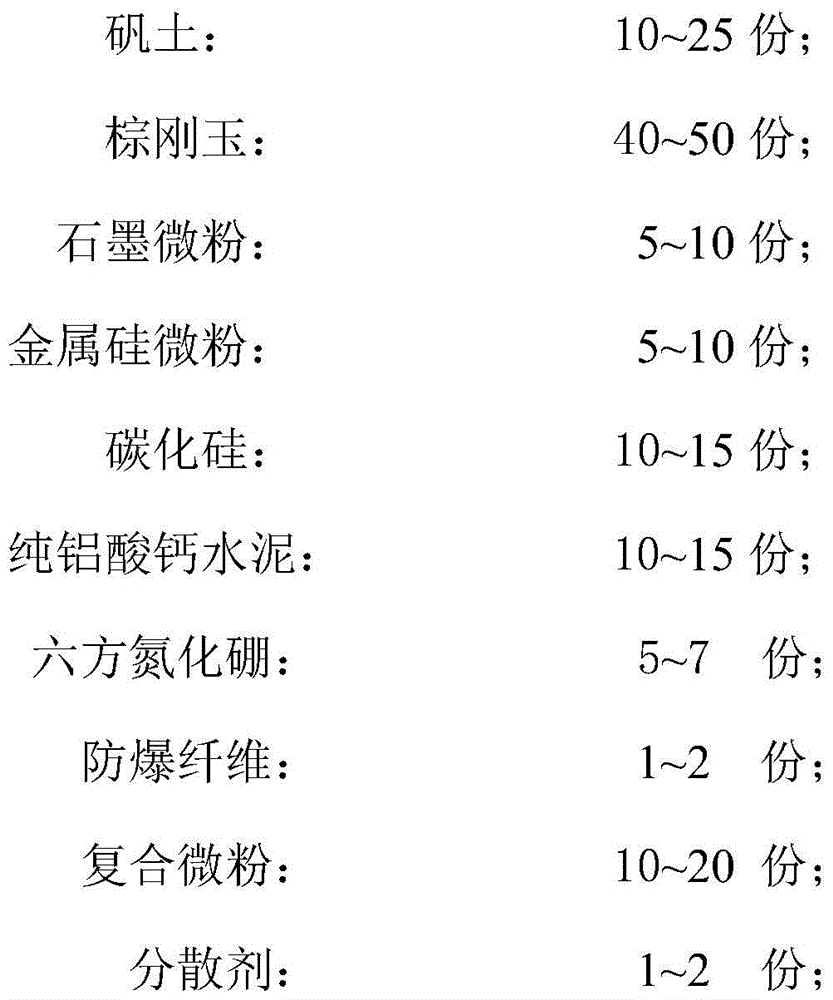

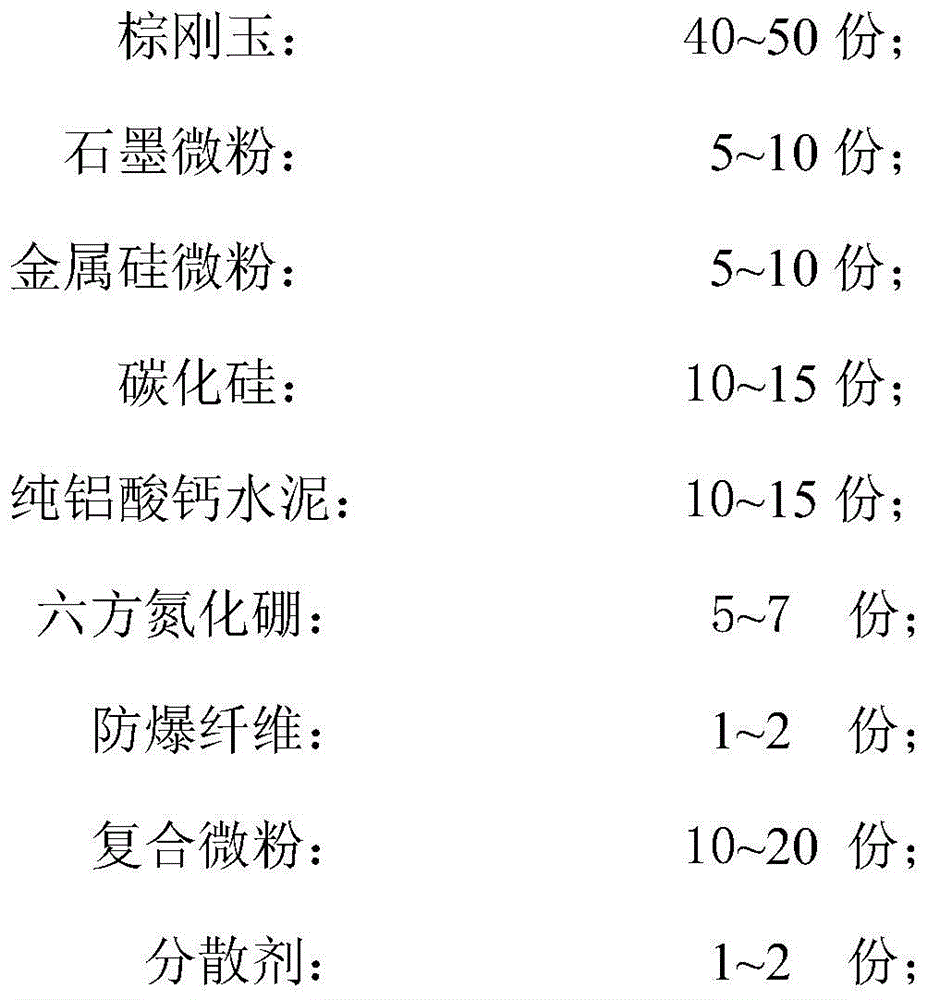

[0022] Embodiment 1: Bauxite: 15 parts; Brown corundum: 40 parts; Graphite fine powder: 5 parts; Metal silicon fine powder: 10 parts; Silicon carbide: 10 parts; Pure calcium aluminate cement: 10 parts; Hexagonal boron nitride: 5 parts parts; explosion-proof fiber: 1 part; composite micropowder: 10 parts; dispersant: 1 part.

Embodiment 2

[0023] Embodiment 2: Bauxite: 20 parts; Brown corundum: 50 parts; Graphite fine powder: 10 parts; Metallic silicon fine powder: 6 parts; Silicon carbide: 12 parts; Pure calcium aluminate cement: 15 parts; Hexagonal boron nitride: 6 parts parts; explosion-proof fiber: 2 parts; composite micropowder: 15 parts; dispersant: 1 part.

Embodiment 3

[0024] Embodiment three: bauxite: 25 parts; Brown corundum: 50 parts; Graphite fine powder: 10 parts; Metal silicon fine powder: 8 parts; Silicon carbide: 15 parts; Pure calcium aluminate cement: 15 parts; Hexagonal boron nitride: 7 parts parts; explosion-proof fiber: 2 parts; composite micropowder: 20 parts; dispersant: 2 parts.

[0025] The invention uses brown corundum, silicon carbide, silicon oxide micropowder, hexagonal boron nitride, Si micropowder, graphite, etc. as raw materials to produce iron channel material with excellent properties. After boron nitride is added to the iron channel material, under high temperature conditions, since boron nitride has a layered structure similar to graphite, the interlayer has a weak molecular bond, so the interface between boron nitride and SiC is weak, The thermal expansion coefficient of the material is small, which reduces the deformation of the material at high temperature and improves the thermal shock resistance of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com