Drag reducer for slickwater fracturing fluid and synthesis method for drag reducer

A synthesis method and hydraulic fracturing technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as poor drag reduction effect, small molecular weight, energy consumption, etc., to avoid post-processing difficulties and fast dissolution speed. , good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

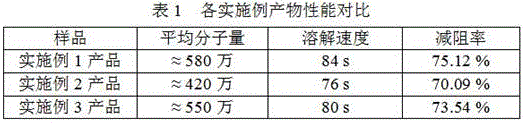

Examples

Embodiment 1

[0023] A drag reducer for slick water fracturing fluid, the raw materials include the following composition by mass ratio:

[0024] 25wt% acrylamide, 23wt% methacrylic acid, 60wt% dispersion medium (composed of ethanol 20wt%, potassium chloride 20wt%, water 60wt%) and 1.5wt% polydimethyldiallyl chloride ammonium chloride.

[0025] The synthesis method is as follows: first, 25wt% of acrylamide, 23wt% of methacrylic acid, 60wt% of dispersion medium (which consists of ethanol 20wt%, potassium chloride 20wt%, water 60wt%) and 1.5wt% polydimethyl Diallyl ammonium chloride is sequentially added to the reaction kettle to form a mixture, and the mixture is evenly stirred. The reaction temperature inside the reaction kettle is controlled within the range of 40-45°C under the protection of nitrogen, and then 0.5wt% is added dropwise to the mixture to initiate Agent (ammonium persulfate oxidizing agent and sodium sulfite reducing agent mass ratio is 1:1) for polymerization reaction, aft...

Embodiment 2

[0027] A drag reducer for slick water fracturing fluid, the raw materials include the following composition by mass ratio:

[0028] 5wt% methylolacrylamide, 30wt% 2-methyl-2acrylamide-1-propanesulfonic acid, 59wt% dispersion medium (which consists of 10wt% isopropanol, 40wt% sodium sulfate, and 50wt% water %) and 5.0wt% polymethacrylamidoethyltrimethylammonium chloride

[0029] The synthesis method is as follows: first, 5wt% of methylolacrylamide, 30wt% of 2-methyl-2 acrylamido-1-propanesulfonic acid, 59wt% of dispersion medium (which is composed of isopropanol 10wt%, sulfuric acid Sodium 40wt%, water 50wt%) and 5.0wt% polymethacrylamidoethyltrimethylammonium chloride were added to the reactor in turn to form a mixture, stirred evenly, and the reaction temperature inside the reactor was controlled at 55-55°C under nitrogen protection. Within the range of 60°C, 1.0wt% initiator (wherein the mass ratio of the oxidant potassium permanganate and the reducing agent sodium thiosulf...

Embodiment 3

[0031] A drag reducer for slick water fracturing fluid, the raw materials include the following composition by mass ratio:

[0032] 10wt% methacrylamide, 13wt% N,N-dimethylacrylamide, 10wt% acrylic acid, 13wt% sodium p-vinylbenzenesulfonate, 50wt% dispersion medium (which consists of 20wt% ethanol, 15wt% isobutanol, 25wt% potassium chloride, 40wt% water) and 3.8wt% polymethacryloyloxyethyl benzyl dimethyl ammonium chloride.

[0033] The synthesis method is as follows: 10wt% methacrylamide, 13wt% N,N-dimethylacrylamide, 10wt% acrylic acid, 13wt% sodium p-vinylbenzenesulfonate, 50wt% dispersion medium (the Composed of ethanol 20wt%, isobutanol 15wt%, potassium chloride 25wt%, water 40wt%) and 3.8wt% polymethacryloxyethylbenzyl dimethyl ammonium chloride were added to the reaction kettle in sequence to form a mixture, Stir evenly, control the reaction temperature in the reaction kettle within the range of 50-55°C under the protection of nitrogen, and then add 0.2wt% initiator dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com