Waterborne polyurethane as well as preparation method and application thereof

A water-based polyurethane and water-based technology, applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of non-sustainable development and dependence on anti-corrosion coatings, achieve good pencil hardness, improve corrosion resistance, and source of raw materials wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

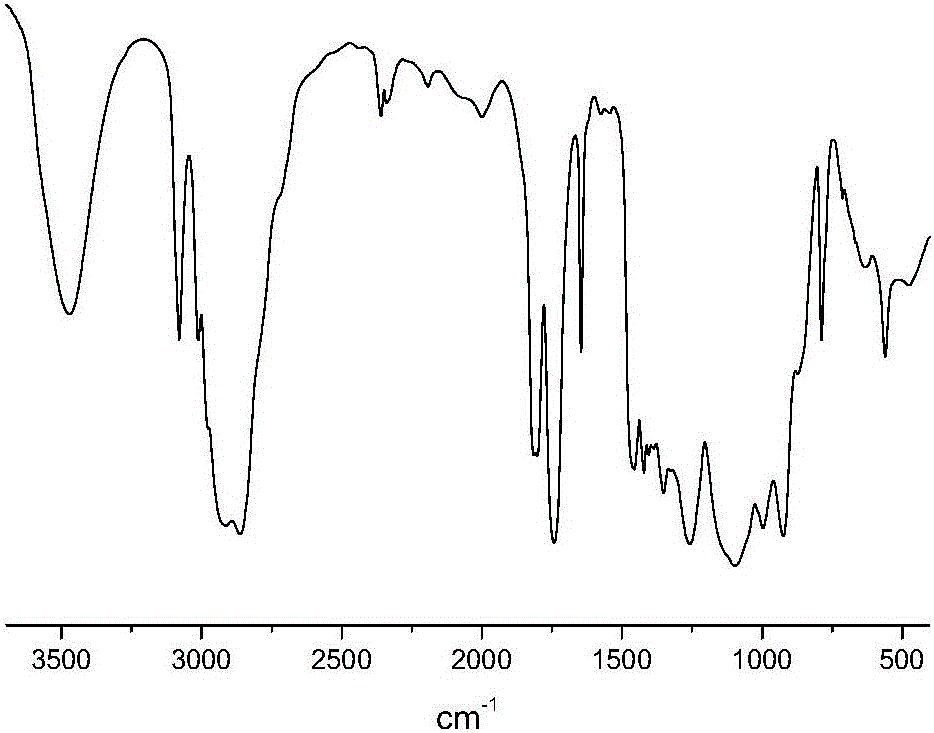

Image

Examples

preparation example Construction

[0057] The present invention also provides a kind of preparation method of waterborne polyurethane, comprising:

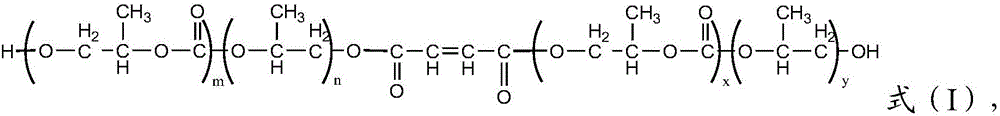

[0058] 1) will have the H-R of formula (I) structure 2 -H, ONC-R 1 -CNO and a solvent are mixed and reacted to obtain a first reaction mixture;

[0059]

[0060] Among them, 1≤m≤30, 1≤n≤35, 1≤x≤30, 1≤y≤35;

[0061] The R 1 It is an arylene group of C6-C35, a cycloalkylene group of C5-C30 or an alkylene group of C3-C12;

[0062] 2) reacting the first reaction mixture, the hydrophilic chain extender N-methyldiethanolamine and the catalyst to obtain the second reaction mixture;

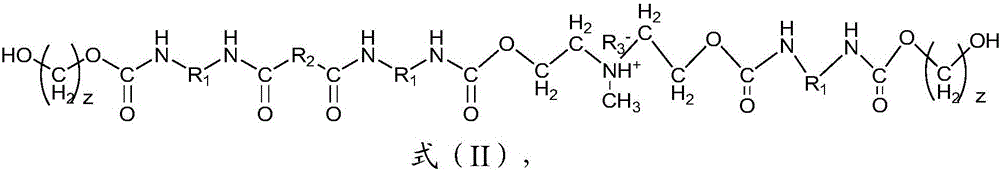

[0063] 3) react the second reaction mixture with diol, use R 3 -H is neutralized to obtain water-based polyurethane with a structure of formula (II);

[0064] The R 3 -R in H 3 is halogen or has a structure of formula (b),

[0065]

[0066] where the R b C1-C5 alkyl or C1-C5 haloalkyl;

[0067]

[0068] According to the present invention, the present invention will have H-...

Embodiment 1

[0077] Embodiment 1 waterborne polyurethane preparation

[0078] 1) Preparation of poly(carbonate-ether) glycol

[0079] The Zn of 0.12g terephthalic acid chain transfer agent and 0.015g [Co (CN) 6] 2 bimetallic catalysts join in the autoclave, add the 16g propylene oxide that contains 5.5g maleic anhydride in the still, then to Fill the kettle with 5.8 g of carbon dioxide and react for 24 hours at a pressure of 2 MPa and a temperature of 55° C. to obtain poly(carbonate-ether) glycol.

[0080] 2) Preparation of waterborne polyurethane:

[0081] Add 120 grams of prepared poly(carbonate-ether) glycol with a molecular weight of 1500 Daltons into the three-necked flask, heat to 100°C, dehydrate at -0.98MPa for 1 hour, cool to 75°C, and protect the mixture under nitrogen , add 200 grams of butanone and 62 grams of diphenylmethane diisocyanate, react for 2 hours, then cool down to 30 ° C, dropwise add 0.0018 grams of dibutyltin dilaurate catalyst, add 9.5 grams of N-methyldiethano...

Embodiment 2

[0083] 139 grams of water-based polyurethane prepared in Example 1, 3 grams of water-based polyaniline powder (prepared according to Patent 201210215967.2 Example 2) were put into a sand mill jar, stirred at a speed of 900 rpm for 2 hours; then at 1300 rpm Add 6.9 grams of photoinitiator Irfacure184, 2 grams of leveling agent BYK-380N, 3 grams of defoamer BYK-019 at a speed of 1000 rpm, and add 100 grams of water-based curing agent Bayhydur3100 at a stirring speed of 1000 rpm , continue stirring for 2 minutes to obtain light-thermal dual curing polyaniline anti-corrosion coating, denoted as WP1.

[0084] Spray the obtained water-based UV-heat dual-curing polyaniline coating WP1 on a pre-polished, degreased, and derusted metal steel plate, level it at 50°C for 3 minutes, irradiate with a 3kw UV lamp, and cure for 20 seconds, then Bake at 55°C for 3 minutes to obtain a WP1 anti-corrosion coating. The paint film performance test was carried out on the coating, and the test resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com