Making method of cotton fabric having conductive and electromagnetic shielding properties

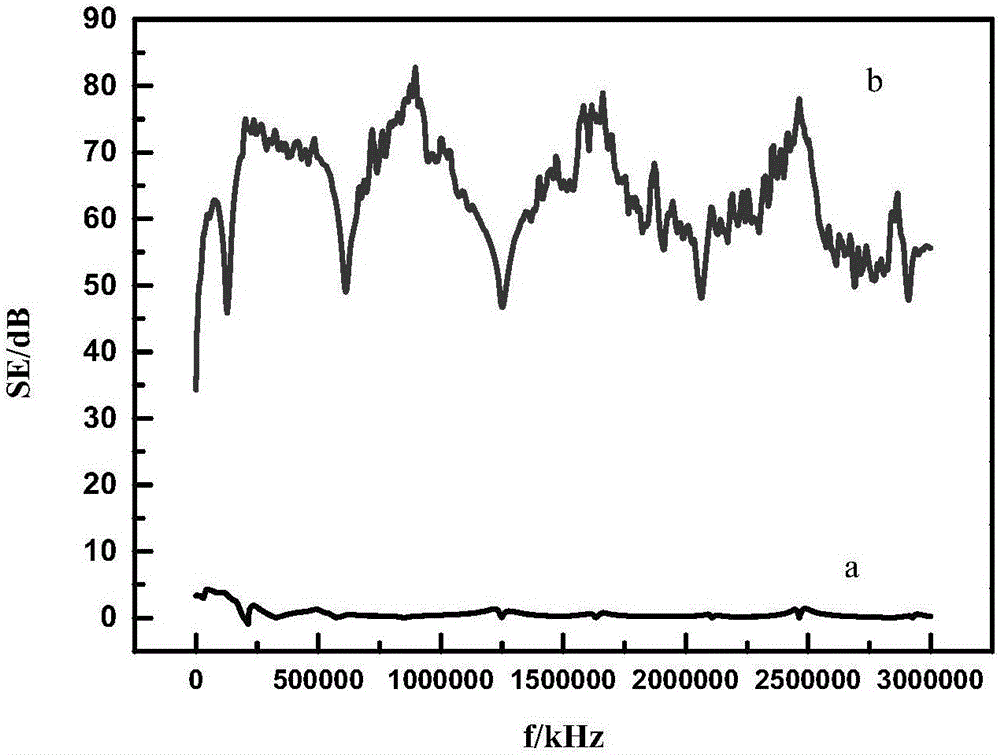

An electromagnetic shielding and cotton fabric technology, applied in the field of preparation of functional cotton fabrics, can solve the problems of low electromagnetic shielding efficiency, cumbersome steps, high cost, etc., and achieve good electromagnetic shielding effect, good corrosion resistance and uniform size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

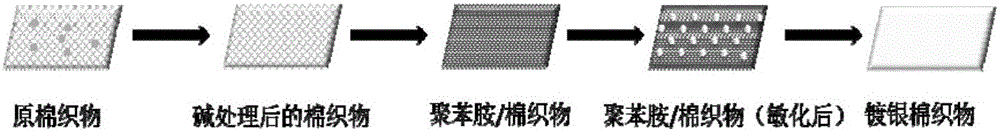

[0037] A kind of processing method of plain cotton fabric, concrete steps are:

[0038] (1) Pretreatment of cotton fabric:

[0039] a. Put the raw cotton fabric in a sodium hydroxide (40g / L) solution with a bath ratio of 1:100, and treat it at 80°C for 1 hour; remove surface impurities, and perform etching;

[0040] b. Dry the treated cotton fabric in an oven at 60° C. for 30 minutes.

[0041] (2) In-situ polymerization of polyaniline on cotton fabric:

[0042] a. Soak the alkali-treated cotton fabric in 200ml of mixed solution containing 0.5M hydrochloric acid and 0.25M aniline for 1h;

[0043] b. Add 40ml of 0.25M ammonium persulfate solution and polymerize for 3h.

[0044] c. After the polymerization reaction is finished, wash repeatedly with deionized water, and dry at room temperature to obtain a polyaniline / cotton fabric.

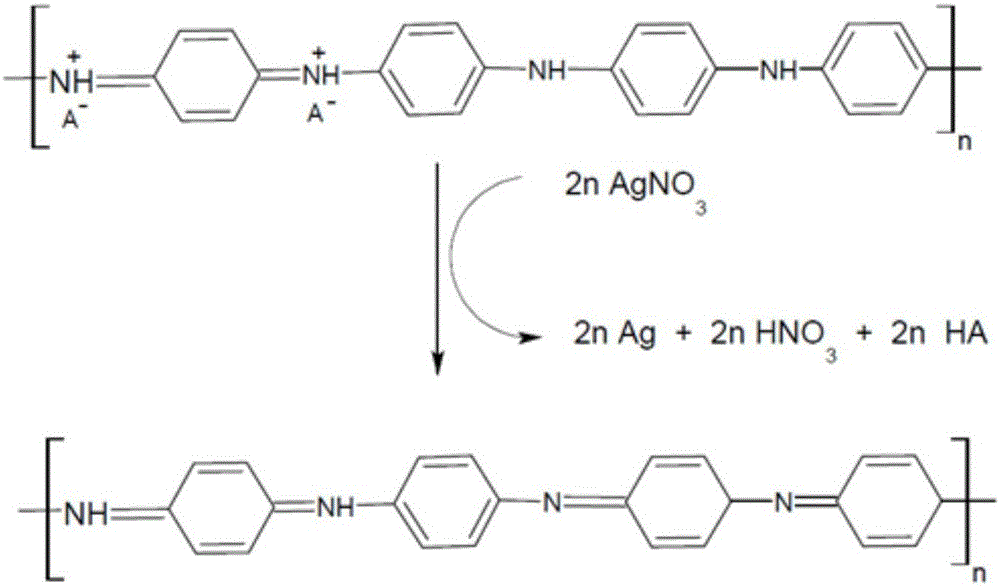

[0045] (3) Electroless silver plating:

[0046] a. Sensitization: put the polyaniline / cotton fabric into 1g / L silver nitrate solution for 5h;

...

Embodiment 2

[0063] A kind of processing method of twill cotton fabric, concrete steps are:

[0064] (1) Pretreatment of cotton fabric:

[0065] a. Put the raw cotton fabric in a sodium hydroxide (50g / L) solution with a bath ratio of 1:100, and treat it at 100°C for 1 hour; remove surface impurities, and perform etching;

[0066] b. Dry the treated cotton fabric in an oven at 60° C. for 30 minutes.

[0067] (2) In-situ polymerization of polyaniline on cotton fabric:

[0068] a. Soak the alkali-treated cotton fabric in 250ml of mixed solution containing 0.5M hydrochloric acid and 0.25M aniline for 1h;

[0069] b. Add 50ml of 0.25M ammonium persulfate solution and polymerize for 5h.

[0070] c. After the polymerization reaction is finished, wash repeatedly with deionized water, and dry at room temperature to obtain a polyaniline / cotton fabric.

[0071] (3) Electroless silver plating:

[0072] a. Sensitization: Put the polyaniline / cotton fabric in 2g / L silver nitrate solution for 5h;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com