Solar selective absorbing coating on ceramic substrate surface and preparation method thereof

A technology of ceramic substrate and absorbing coating, applied in the field of solar selective absorbing coating on the surface of ceramic substrate and its preparation, can solve problems such as large heat radiation loss, and achieve the effects of reducing emissivity and preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

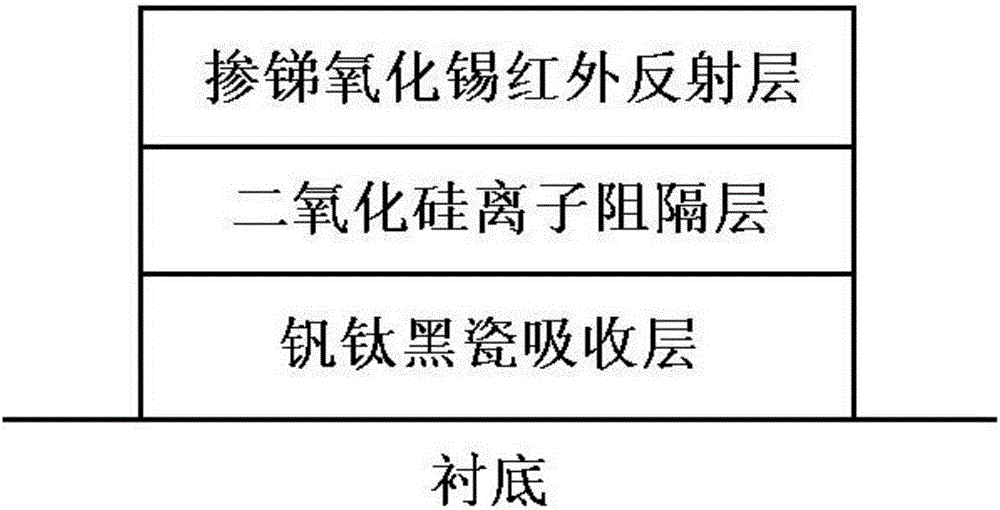

[0029] The film layer structure is ceramic substrate / vanadium titanium black porcelain / SiO 2 / ATO, prepared as follows:

[0030] (1) Preparation of vanadium-titanium black porcelain absorption layer: mix 100g base material, 0.1-0.5g sodium carboxymethyl cellulose and 40-80g water to obtain glaze slurry; wherein, the composition of the base material is: SiO 2 25-49%, Al 2 o 3 20-25%, Fe 2 o 3 20~25%, V 2 o 5 2-4%, TiO 2 4~8%, GaO1~3%, MgO1~3%, K 2 O1~3%, Na 2 O2 ~ 4%. The vanadium-titanium glaze slurry is applied on the surface of the blank to form a green body by the method of spraying glaze, and the green body is trimmed and dried to obtain a fine body. Send the compact into the kiln, complete sintering at a high temperature of 1200°C, and obtain a vanadium-titanium black porcelain absorbing layer after cooling;

[0031] (2) Preparation of silicon dioxide ion barrier layer: Take 50ml tetraethyl orthosilicate and add it to 200mL ethanol, adjust the pH value of the s...

Embodiment 2

[0035] Referring to Example 1, the difference is that when preparing the antimony-doped tin oxide infrared reflective layer, the volume ratio of glacial acetic acid to ethylene glycol is 1:2, and the reaction temperature is 60°C. The prepared solar selective absorbing coating has an absorptivity of 92% and an emissivity of 21%.

Embodiment 3

[0037] Referring to Example 1, the difference is that when preparing the antimony-doped tin oxide infrared reflective layer, the volume ratio of glacial acetic acid to ethylene glycol is 1:3, and the reaction temperature is 100°C. The prepared solar selective absorbing coating has an absorptivity of 90% and an emissivity of 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com