Method for one-step hydrothermal synthesis preparation of composite anode material of solid oxide fuel cell

A technology of solid oxide and composite cathode, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reduced reactive sites, reduced three-phase interface, uneven cathode mixing, etc., to achieve improved performance, uniform distribution, and avoid The effect of active site reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

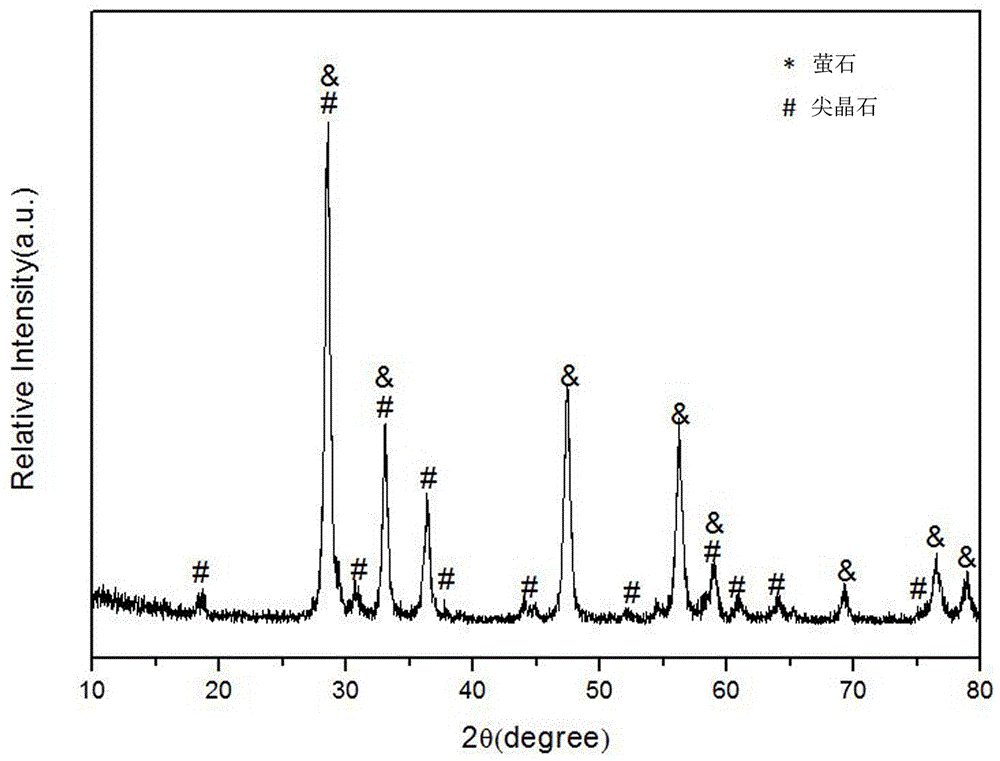

[0027] Preparation of Mn by one-step hydrothermal synthesis 1.5 co 1.5 o 4 / SDC=50:50wt% composite cathode material, where Mn 1.5 co 1.5 o 4 is 0.0014mol, weigh 0.5147gMn(CH 3 COO) 2 4H 2 O (analytically pure), 0.6112gCo(NO 3 ) 2 ·6H 2 O (analytically pure), 0.6600gCe (NO 3 ) 3 ·6H 2 O (analytical grade), 0.1689gSm (NO 3 ) 3 ·6H 2 O (analytically pure), be dissolved in the deionized water of 50ml completely, stir 30min, then slowly drip the NaOH of 3mol / L and adjust the pH value of solution to be 10-11 under strong stirring state, continue to stir 30min, form uniform Suspension, transfer the precursor solution to a 200ml reaction kettle, seal it and place it in an oven to heat up to 180°C, keep it for 12h, then cool it down naturally, after the reaction is completed, filter the product, wash it, and dry it at 80°C for 6-7h. After uniform grinding, the cathode powder was collected, and the powder was characterized by XRD. figure 1 For the obtained XRD spectrum....

Embodiment 2

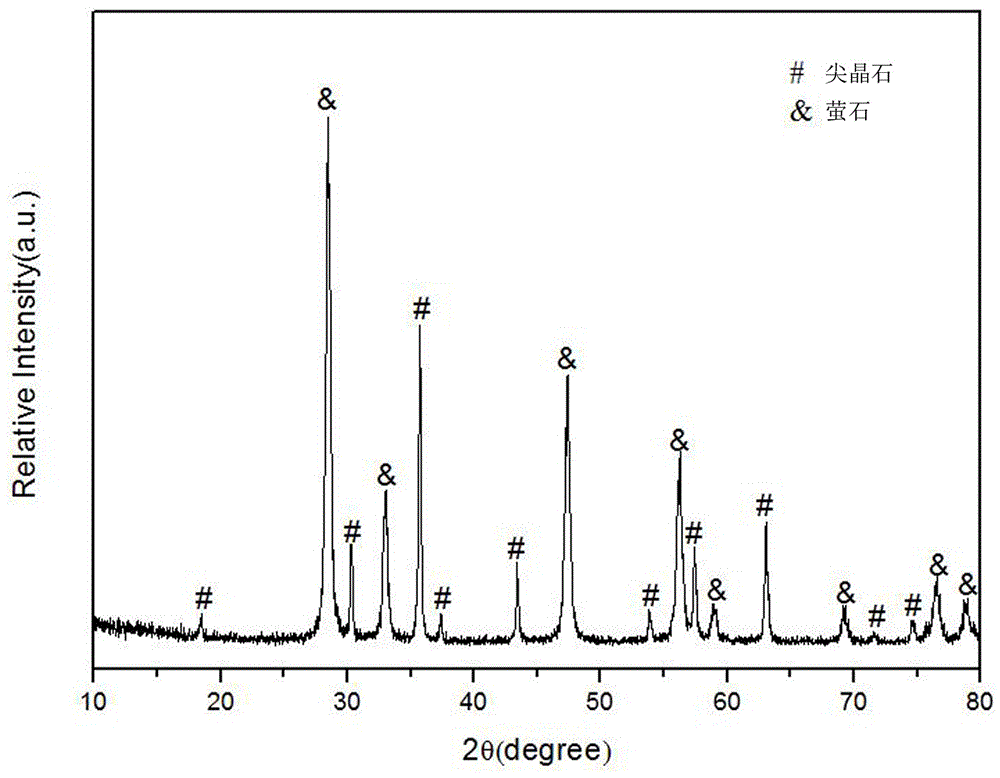

[0029] Preparation of Mn by one-step hydrothermal synthesis 1.5 co 1.5 o 4 / SDC=50:50wt% composite cathode material, where Mn 1.5 co 1.5 o 4 is 0.0014mol, weigh 0.5147gMn(CH 3 COO) 2 4H 2 O (analytically pure), 0.6112gCo(NO 3 ) 2 ·6H 2 O (analytically pure), 0.6600gCe (NO 3 ) 3 ·6H 2 O (analytical grade), 0.1689gSm (NO 3 ) 3 ·6H 2O (analytically pure), completely dissolved in the mixed solution of 26ml of deionized water and 40ml of absolute ethanol, stirred for 30min, then slowly added dropwise 25%-28% ammonia water under strong stirring and adjusted the pH value of the solution 10-11, continue to stir for 30 minutes to form a uniform suspension, transfer this precursor solution to a 100ml reaction kettle, seal it and place it in an oven to heat up to 180°C, keep it for 12 hours, and then cool it down naturally. The product is filtered, washed, dried at 80° C. for 6-7 hours, ground evenly and collected to obtain cathode powder.

[0030] Mn can also be prepare...

Embodiment 3

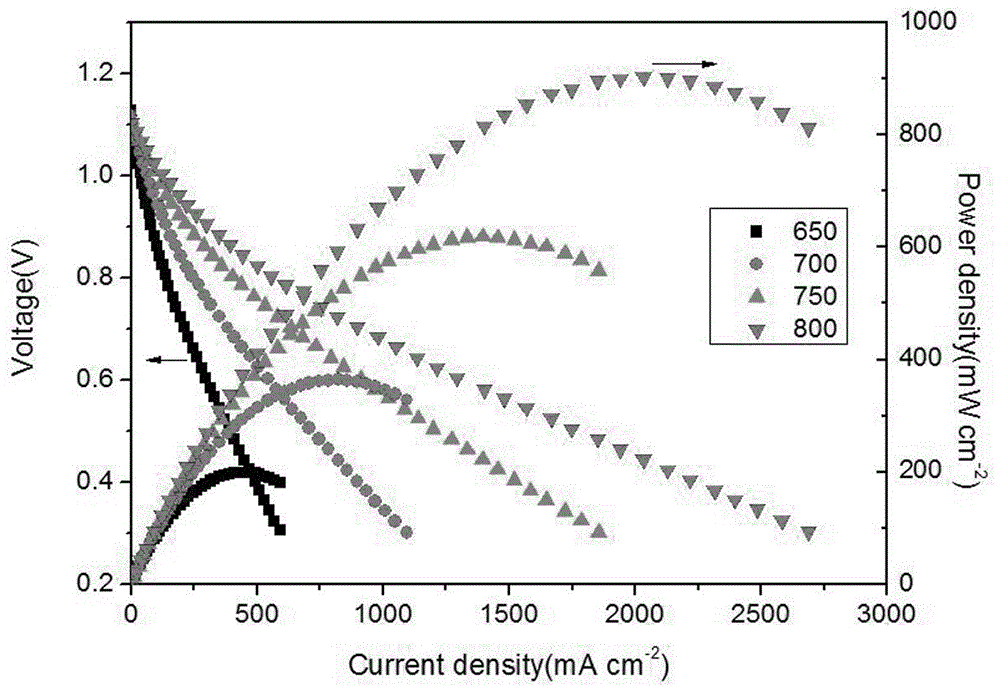

[0034] Preparation of NiFe by one-step hydrothermal synthesis 2 o 4 / SDC=50:50wt% composite cathode material, in which NiFe 2 o 4 is 0.006mol, weigh 1.7447gNi(NO 3 ) 2 ·6H 2 O (analytically pure), 4.848gFe (NO 3 ) 3 9H 2 O (analytically pure), 2.8137gCe (NO 3 ) 3 ·6H 2 O (analytically pure), 0.7200gSm (NO 3 ) 3 ·6H 2 O (analytically pure), completely dissolved in 60ml deionized water and stirred evenly. Take another beaker to weigh a certain amount of sodium hydroxide, dissolve it in deionized water, then add it dropwise into the mixed solution under vigorous stirring and adjust the pH value of the solution to 10-11, and continue stirring for 30 minutes to form a uniform suspension. For turbid liquid, transfer the precursor solution to a 100ml reaction kettle, seal it, place it in an oven and heat it up to 180°C, keep it for 12 hours, then cool it down naturally, after the reaction is completed, filter the product, wash it, dry it at 80°C for 6-7 hours, and grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com