Soluble granule for preventing and treating disease and insect damage to Radix Astragali

A soluble, pest-resistant technology, applied in biocides, fungicides, biocides, etc., can solve the problem of easy decomposition of active ingredients of pesticides, and achieve good storage life, high content of active ingredients in pesticides, and smooth processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

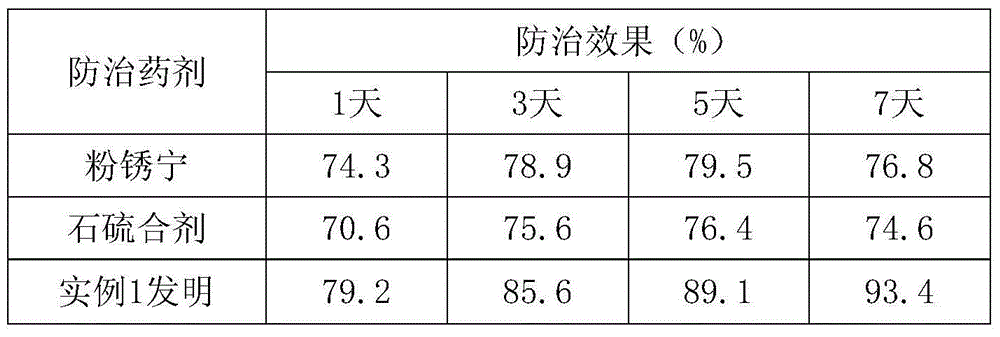

[0028] Example 1 to the prevention and control method of astragalus powdery mildew

[0029] (1) 8 kg of fenxining, 20 kg of lime sulfur mixture, after reaching 325 mesh to 400 mesh, add 5 kg of wetting and dispersing agent sodium lauryl sulfate, 5 kg of naphthalene sulfonate, and 52 kg of urea; the selected penetrant is sulfonic acid Add 5 kg of ethanol to 10 kg of dioctyl succinate sodium salt, stir, and set aside;

[0030] (2) The mixture was mixed without gravity for 10 minutes, and the prepared mixture of ethanol and penetrant was added by spraying during the mixing process.

[0031] (3) extrusion granulation, drying at 75° C. to obtain dry granules with a particle diameter of 1 mm;

[0032] (4) After the dried granules are sieved, they are packaged to obtain soluble granules; oversized granules or dust and dedusting powder are returned

[0033] Re-granulate after mixing with virgin material in a gravity-free mixer.

[0034] The preventive effect is:

[0035]

example 2

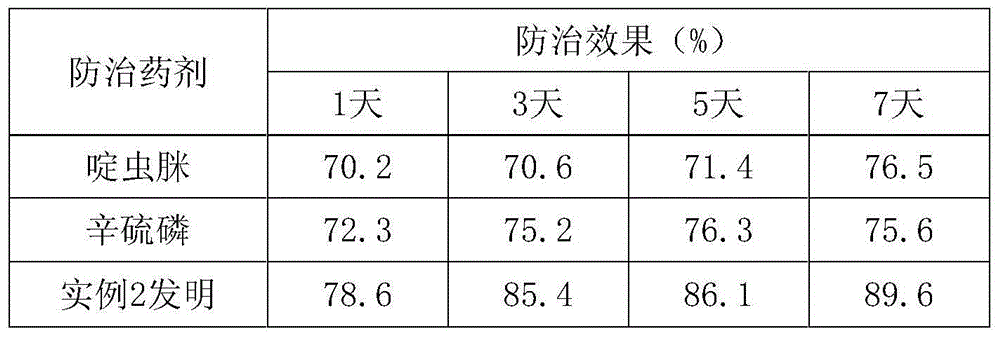

[0036] The control method of example 2 astragalus seed wasps

[0037] (1) 12kg of acetamiprid, 10kg of phoxim, and after reaching 325 mesh to 400 mesh, add 5kg of wetting and dispersing agent sodium lauryl sulfate, 5kg of naphthalenesulfonate, 22kg of urea, and 36kg of potassium sulfate; The selected penetrating agent is dioctyl sulfosuccinate sodium salt, add 5 kg of ethanol to 10 kg, stir, and set aside;

[0038] (2) The mixture was mixed without gravity for 10 minutes, and the prepared mixture of ethanol and penetrant was added by spraying during the mixing process.

[0039] (3) extrusion granulation, drying at 75° C. to obtain dry granules with a particle diameter of 1 mm;

[0040] (4) After the dried granules are sieved, they are packaged to obtain soluble granules; oversized granules or dust and dedusting powder are returned

[0041] Re-granulate after mixing with virgin material in a gravity-free mixer.

[0042] The preventive effect is:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com