Heat-resisting protective agent for TGEV and PEDV bigeminy freeze-drying live vaccine and preparing method and application of heat-resisting protective agent

A heat-resistant protective agent, TGEV technology, applied in the field of vaccines, can solve the problem of lack of heat-resistant protective agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

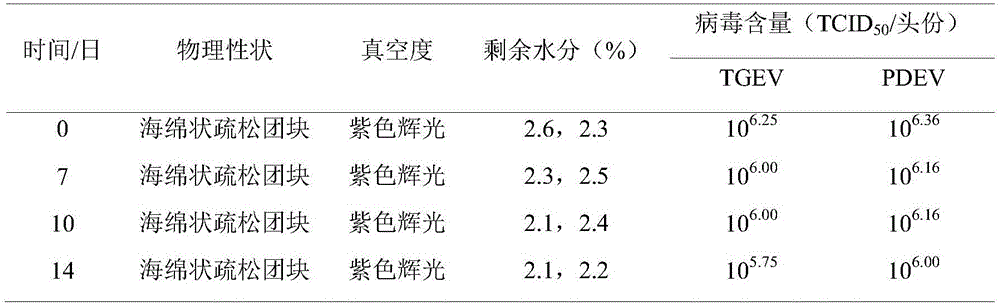

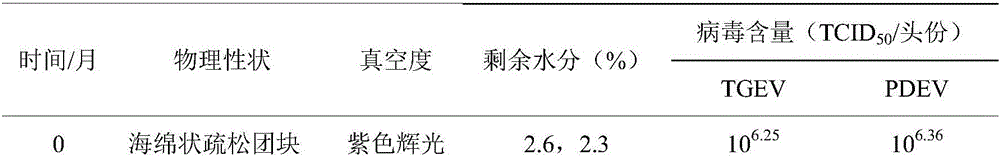

[0036] Embodiment 1 (preparation and inspection of porcine transmissible gastroenteritis, epidemic diarrhea dual heat-resistant protective agent live vaccine)

[0037] 1. Preparation of heat-resistant protective agent

[0038] 1.1 Weigh macromolecular substances such as gelatin and polyvinylpyrrolidone, dissolve them in water for injection in proportion, and sterilize under high pressure at 115°C for 20 minutes, as liquid A.

[0039] 1.2 Dissolve small molecular substances such as lactose, hydrolyzed milk protein, trehalose, L-arginine, and sodium glutamate in water for injection in proportion, and filter and sterilize with a 0.22 μm filter membrane as liquid B.

[0040] 1.3 Mix the above-mentioned liquid A and liquid B at a ratio of 1:1 to obtain a heat-resistant protective agent for porcine transmissible gastroenteritis and epidemic diarrhea dual live vaccine, wherein the proportions of each component are gelatin 2%, PVPK305%, lactose 6%, hydrolyzed milk protein 1%, trehalo...

Embodiment 2

[0063] Embodiment 2 (preparation and inspection of porcine transmissible gastroenteritis, epidemic diarrhea dual heat-resistant protective agent live vaccine)

[0064] 1. Preparation of heat-resistant protective agent

[0065] 1.1 Dissolve macromolecular substances such as gelatin and polyvinylpyrrolidone in proportion with ultrapure water, and sterilize under high pressure at 116°C for 20 minutes, as liquid A;

[0066] 1.2 Dissolve lactose, hydrolyzed milk protein, trehalose, L-arginine, sodium glutamate and other small molecular substances in ultrapure water in proportion, and filter and sterilize with a 0.22 μm filter membrane as liquid B;

[0067] 1.3 Mix the above liquid A and liquid B at a ratio of 1:1 to obtain the heat-resistant protective agent for porcine transmissible gastroenteritis and epidemic diarrhea dual live vaccine, wherein the proportions of each component are gelatin 1.5%, gelatin PVPK306%, lactose 8%, hydrolyzed milk protein 1.5%, trehalose 2%, L-arginin...

Embodiment 3

[0089] Example 3 Preparation and inspection of porcine transmissible gastroenteritis and epidemic diarrhea dual heat-resistant protective agent live vaccine

[0090] 1. Preparation of heat-resistant protective agent

[0091] 1.1 Dissolve macromolecular substances such as gelatin and polyvinylpyrrolidone in proportion with ultrapure water, and sterilize under high pressure at 121°C for 15 minutes, as liquid A;

[0092] 1.2 Dissolve small molecular substances such as lactose, hydrolyzed milk protein, trehalose, L-arginine, and sodium glutamate in proportion to ultrapure water, and filter and sterilize with a 0.22 μm filter membrane as liquid B;

[0093] 1.3 Mix the above-mentioned liquid A and liquid B at a ratio of 1:1 to obtain a heat-resistant protective agent for porcine transmissible gastroenteritis and epidemic diarrhea dual live vaccine, wherein the proportions of each component are gelatin 1%, gelatin 1%, PVPK308%; of which lactose 4%, hydrolyzed milk protein 3%, trehal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com