Composite heat stabilizer and preparing method thereof

A compound heat stabilizer and heat stabilizer technology, which is applied in the field of heat stabilizers for synthetic resins, can solve the problems of easy precipitation, uneven dispersion, and easy sublimation of profiles, and achieve good initial stability, simple operation, and improved fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

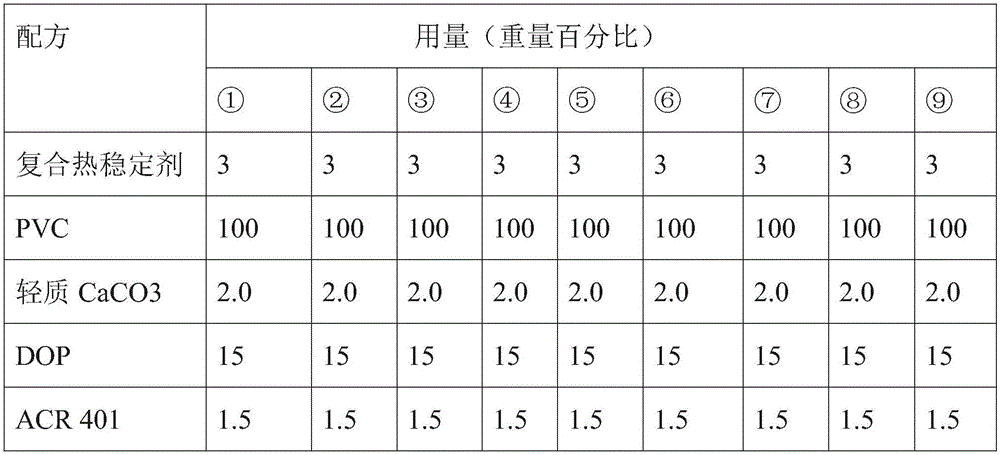

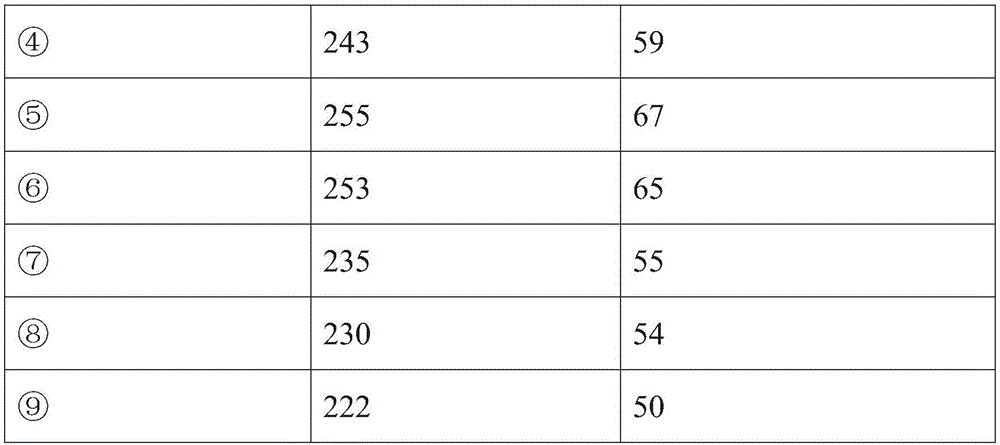

Examples

Embodiment 1

[0026] Embodiment 1, a kind of composite thermal stabilizer

[0027] This embodiment 1 provides a composite heat stabilizer, including the following components in parts by weight: 3.5 parts of heat stabilizer, 8 parts of bisphenol A diglycidyl ether, 1 part of light stabilizer, 3 parts of stearic acid amide and 10 parts of mineral oil, wherein the light stabilizer is composed of bis(2,2,6,6-tetramethylpiperidin-4-ol) and phenyl salicylate in a weight ratio of 1:1, The heat stabilizer is composed of zinc stearate, lanthanum salicylate and phosphite in a weight ratio of 1:1:4.

[0028] Preparation:

[0029] A) Preparation of lanthanum salicylate: take salicylic acid, lanthanum nitrate and sodium hydroxide in a molar ratio of 1:1:2, and dissolve sodium hydroxide in an appropriate amount of distilled water to make a 2.0mol / L NaOH solution; Put the salicylic acid into a 500mL three-necked bottle, add an appropriate amount of absolute ethanol to the three-necked bottle, add lantha...

Embodiment 2

[0031] Embodiment 2, a kind of composite thermal stabilizer

[0032]This embodiment 2 provides a composite heat stabilizer, including the following components in parts by weight: 6 parts of heat stabilizer, 12 parts of ethylene glycol diglycidyl ether, 3 parts of light stabilizer, 5 parts of stearic acid amide and 12 parts of mineral oil, wherein the light stabilizer is composed of bis(2,2,6,6-tetramethylpiperidin-4-ol) and phenyl salicylate in a weight ratio of 1:1, The heat stabilizer is composed of zinc stearate, lanthanum salicylate and phosphite in a weight ratio of 1:0.5:2.

[0033] The preparation method refers to Example 1.

Embodiment 3

[0034] Embodiment 3, a kind of composite thermal stabilizer

[0035] This embodiment 3 provides a composite heat stabilizer, including the following components in parts by weight: 7 parts of heat stabilizer, 15 parts of bisphenol A diglycidyl ether, 5 parts of light stabilizer, 6 parts of stearic acid amide and 15 parts of mineral oil, wherein the light stabilizer is composed of bis(2,2,6,6-tetramethylpiperidin-4-ol) and phenyl salicylate in a weight ratio of 1:1, The heat stabilizer is composed of zinc stearate, cerium salicylate and phosphite in a weight ratio of 1:1:4.

[0036] Preparation method: change lanthanum nitrate in step A) to cerium nitrate, and bisphenol a diglycidyl ether in step B) to ethylene glycol diglycidyl ether, and refer to the preparation method in Example 1 for the remaining operations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com