Thermal management system for power battery of pure electric vehicle

A thermal management system, pure electric vehicle technology, applied in the field of pure electric vehicle power battery thermal management system, can solve problems such as constant temperature or temperature fluctuation is difficult to achieve, heat accumulation cannot be effectively released, and liquid fluidity control requirements are high. Achieve the effect of improving charge and discharge efficiency, simple structure, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

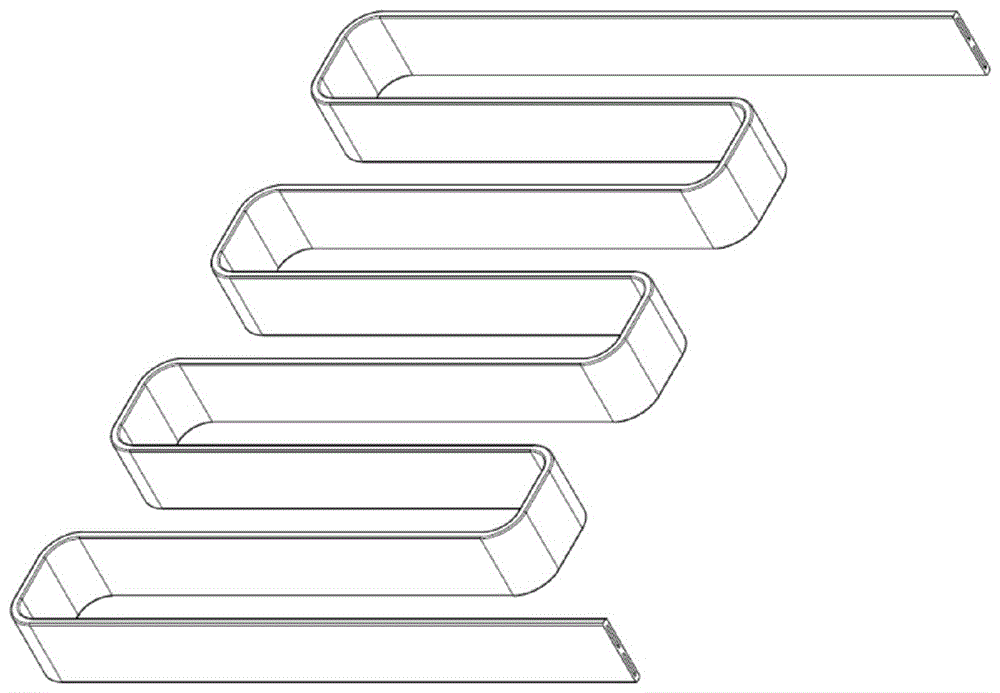

[0024] Embodiment two, see Figure 1~8 As shown, it is basically the same as the first embodiment, the difference is that the heat-conducting silicone tube is a profile-type tube made of polymer elastic material, and the profile-type tube is provided with multiple parallel lumens, see Figure 4 and Figure 5 As shown, according to actual use requirements, the inner cavity can have an elliptical or circular cross-section.

[0025] As mentioned above, the heat-conducting silicone hose belt is a profile-type hose belt made of special silicone rubber material, which has excellent high temperature resistance (250-300°C) and low temperature resistance (-40-60°C) performance, and has good Physiological stability, excellent resilience and small permanent deformation (less than 50% in 48 hours at 200°C), breakdown voltage (20-25KV / mm), ozone resistance, UV resistance, radiation resistance, oil resistance, The pipe tape is soft, and high thermal conductivity silicone pipe tape can be ...

Embodiment 2

[0026] As mentioned above, the combined reducing joint includes fixed tailstock 1 and fixed tailstock 2, the pipe belt joint is fixedly connected with fixed tailstock 1, the outer circulation pipe joint is fixedly connected with fixed tailstock 2, fixed tailstock 1 and fixed tailstock The second is sealed and connected through fasteners, and the tailstock is fixed; the second is fixed to the battery module shell through bolts.

[0027] As mentioned above, there is an O-shaped sealing ring between the fixed tailstock 1 and the fixed tailstock 2. The fixed tailstock 1 and the fixed tailstock 2 are integrated structures. Variable-diameter sealing connection, good sealing effect, avoid foreign matter, dust, etc. from entering, safety and reliability are further guaranteed.

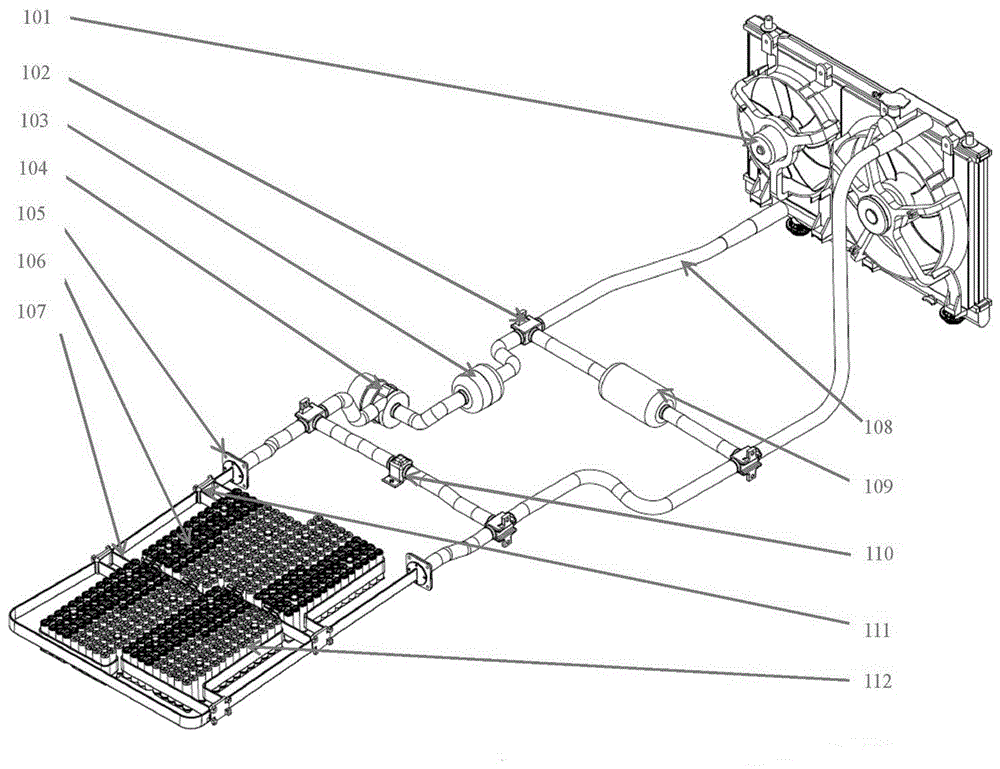

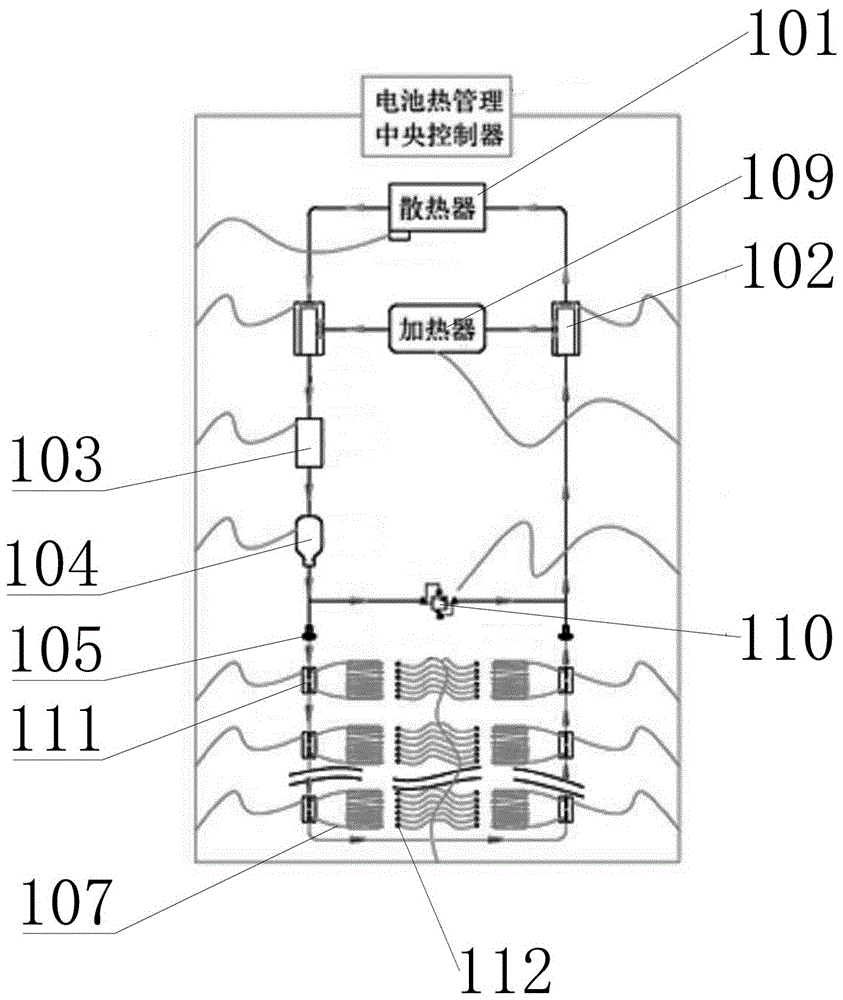

[0028] Working principle: The coolant is stored by the radiator 101, and through the external circulation pipeline 108, it passes through the two-position three-way solenoid valve 102, the coolant filter 103, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com