Method for preparing boride coating on stainless steel surface

A stainless steel and coating technology, which is applied in the field of stainless steel surface modification treatment, can solve the problems of high brittleness, easy peeling, easy formation of micro cracks or deformation of the coating, and achieve the effect of improving electrical conductivity, improving compactness and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Surface pretreatment of stainless steel substrate

[0024] Cut the 304L stainless steel into samples of length × width × height 10mm × 10mm × 5mm, and use 400, 2000 # Grind with SiC sandpaper step by step to remove the surface oxide layer, then put it in acetone solution to degrease and clean for 3 minutes, wash with deionized water and dry;

[0025] (2)TiB 2 Preparation of deposited electrodes

[0026] Pure TiB 2 The powder is loaded into a steel mold, held at a pressure of 7 MPa for 4 minutes for compression molding, and then the compressed TiB 2 Under the protection of argon, it firstly rises from room temperature (25°C) to 450°C in 1.5 hours, then rises to 1600°C in 2 hours, then rises from 1600°C to 1900°C in 1.5 hours, and keeps it at 1900°C for 4 hours. Cool to room temperature;

[0027] (3) Connect the 304L stainless steel after surface treatment in step (1) to the cathode of high-energy micro-arc alloying equipment, and the TiB prepared in step (2) 2 ...

Embodiment 2

[0030] (1) Surface pretreatment of stainless steel substrate

[0031] Concrete operation is with embodiment 1;

[0032] (2)TiB 2 / C deposition electrode preparation

[0033] TiB 2 , After the toner is sieved through an 80-mesh filter, the TiB 2 The powder and carbon powder are doped and mixed uniformly, among which TiB 2 Powder is 98.0wt.%, carbon powder is 2.0wt.%,

[0034] Compression molding after ball milling again, ball milling adopts planetary ball mill, grinding medium is zirconia ball, wherein the ratio of large ball, medium ball and small ball is 1:2:4, adjust the rotating speed of ball mill to be 200r / min, and the ball milling time is 2h; TiB after ball milling 2 / C powder is loaded into a steel mold, held at a pressure of 7MPa for 4 minutes and pressed into shape;

[0035] Then the pressed TiB 2 / C Under the protection of argon, first rise from room temperature (25°C) to 450°C in 1.5 hours, then rise to 1600°C in 2 hours, then rise from 1600°C to 1900°C in 1...

Embodiment 3

[0040] (1) Surface pretreatment of stainless steel substrate

[0041] Concrete operation is with embodiment 1,

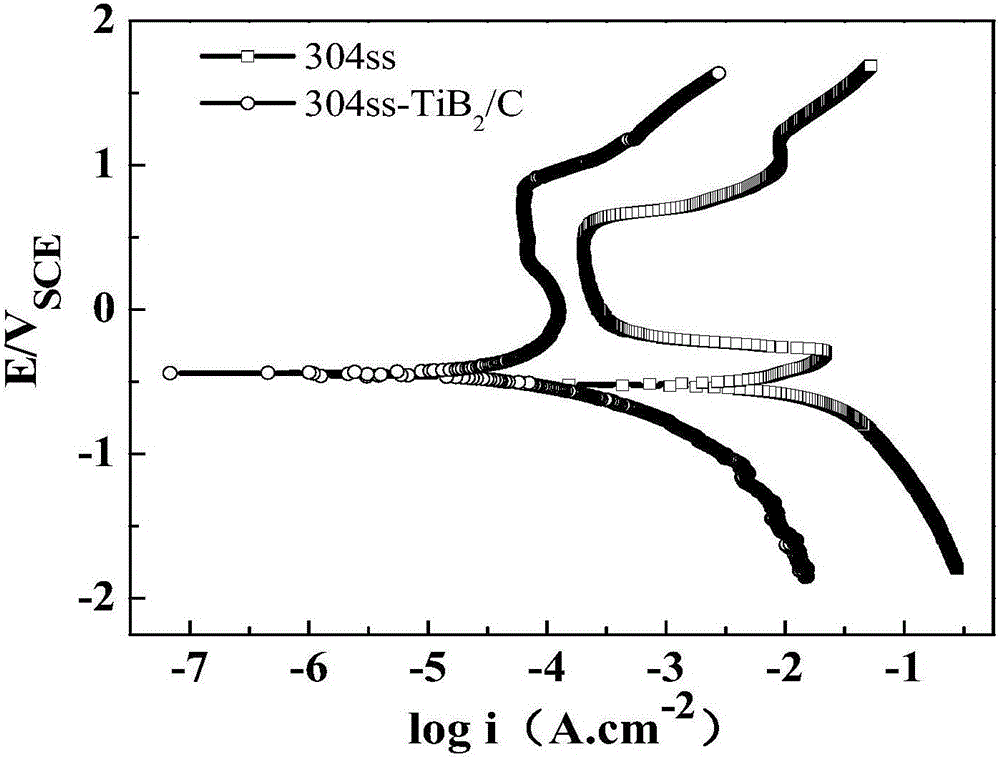

[0042] At this time, the stainless steel substrate is at 0.3MH 2 SO 4 Corrosion polarization curve in +2ppmF solution is attached figure 1 shown in;

[0043] (2)TiB 2 / C deposition electrode preparation

[0044] TiB 2 , After the toner is sieved through an 80-mesh filter, the TiB 2 The powder and carbon powder are doped and mixed uniformly, among which TiB 2 The powder is 96.0wt.%, the carbon powder is 4.0wt.%, and the ball milling, pressing molding, and sintering processes are the same as in Example 2;

[0045] (3) High-energy micro-arc alloying deposition

[0046] Concrete operation is with embodiment 2,

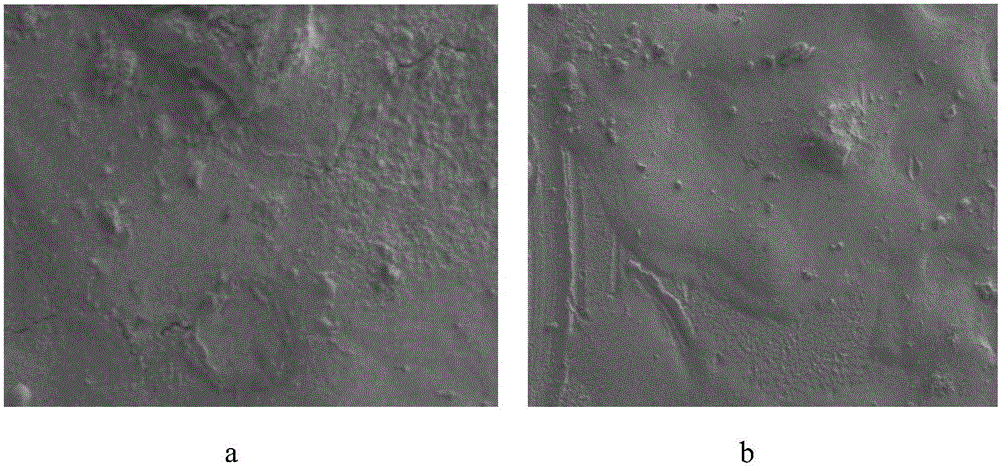

[0047] A layer of 18 μm thick and uniform and dense TiB was obtained after deposition for 4 minutes 2 / C coating, the coating surface has no obvious defects (if attached figure 2 shown in b), and provide good protection for the matrix under acidic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com